Automatic bundling machine and method of strip coil

A strapping machine, automatic technology, applied in the direction of strapping materials, strapping machine parts, paper/cardboard containers, etc., can solve the problems of poor use effect, high temperature radiation annealing, low working life of equipment, etc., to achieve long life, equipment The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

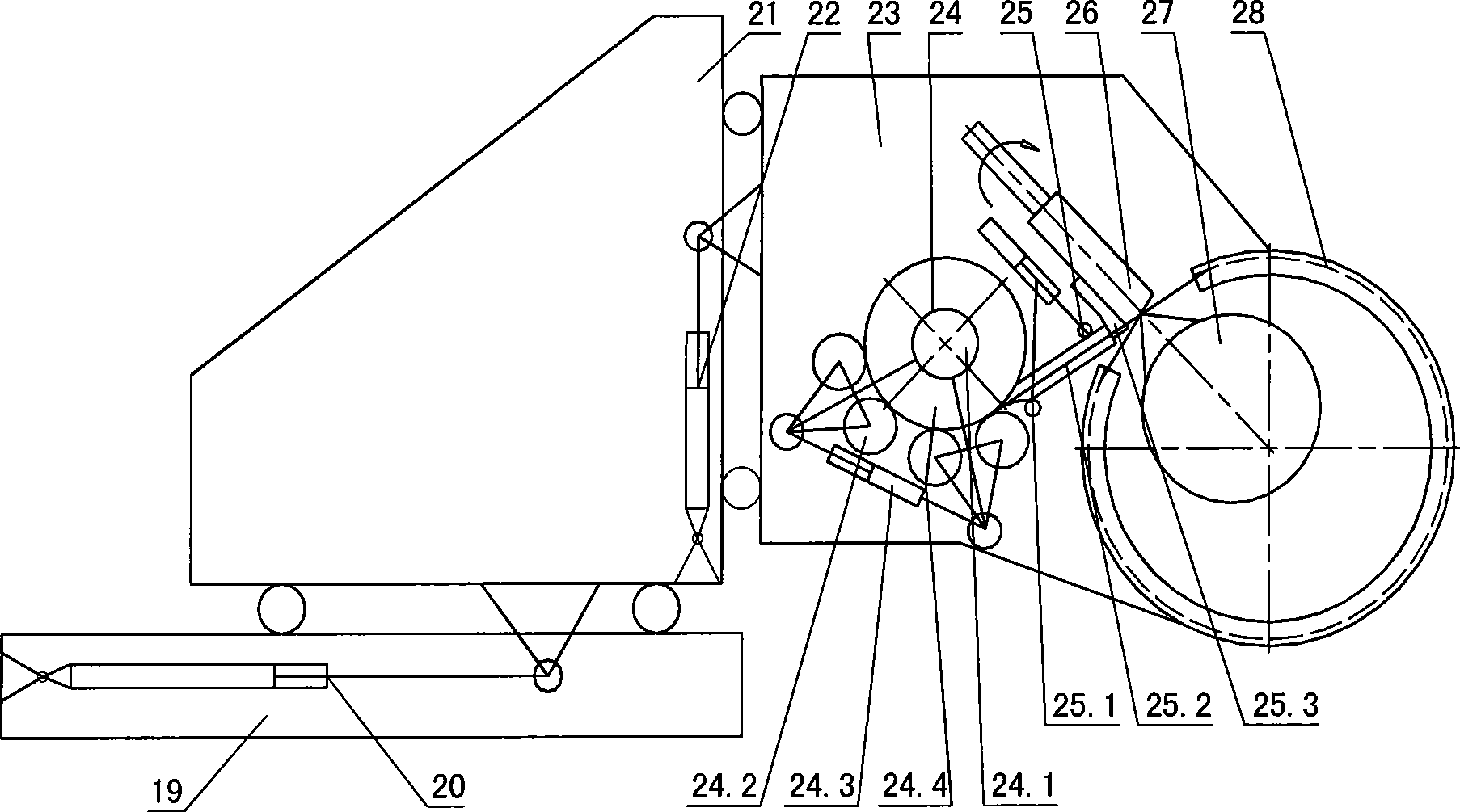

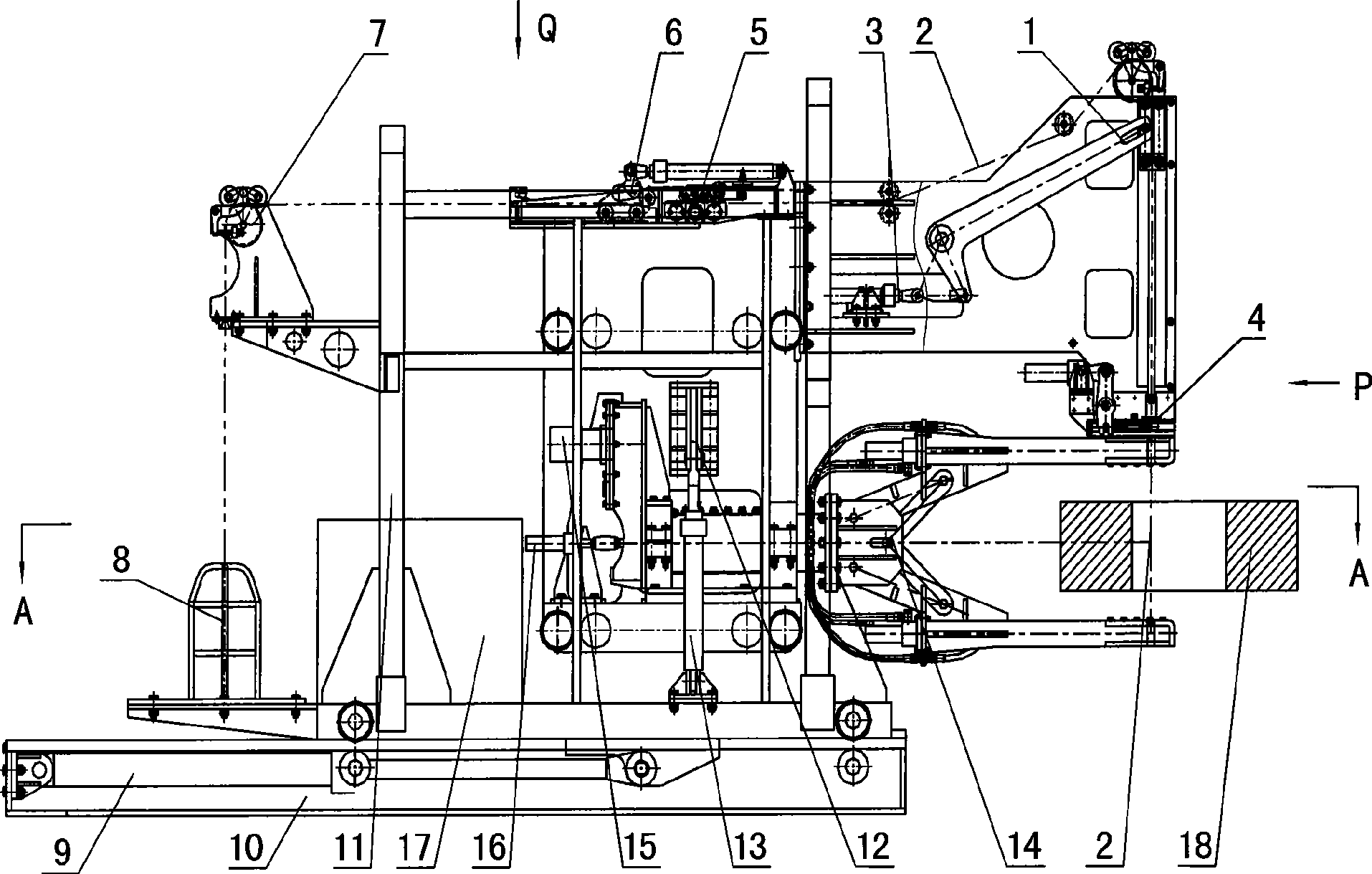

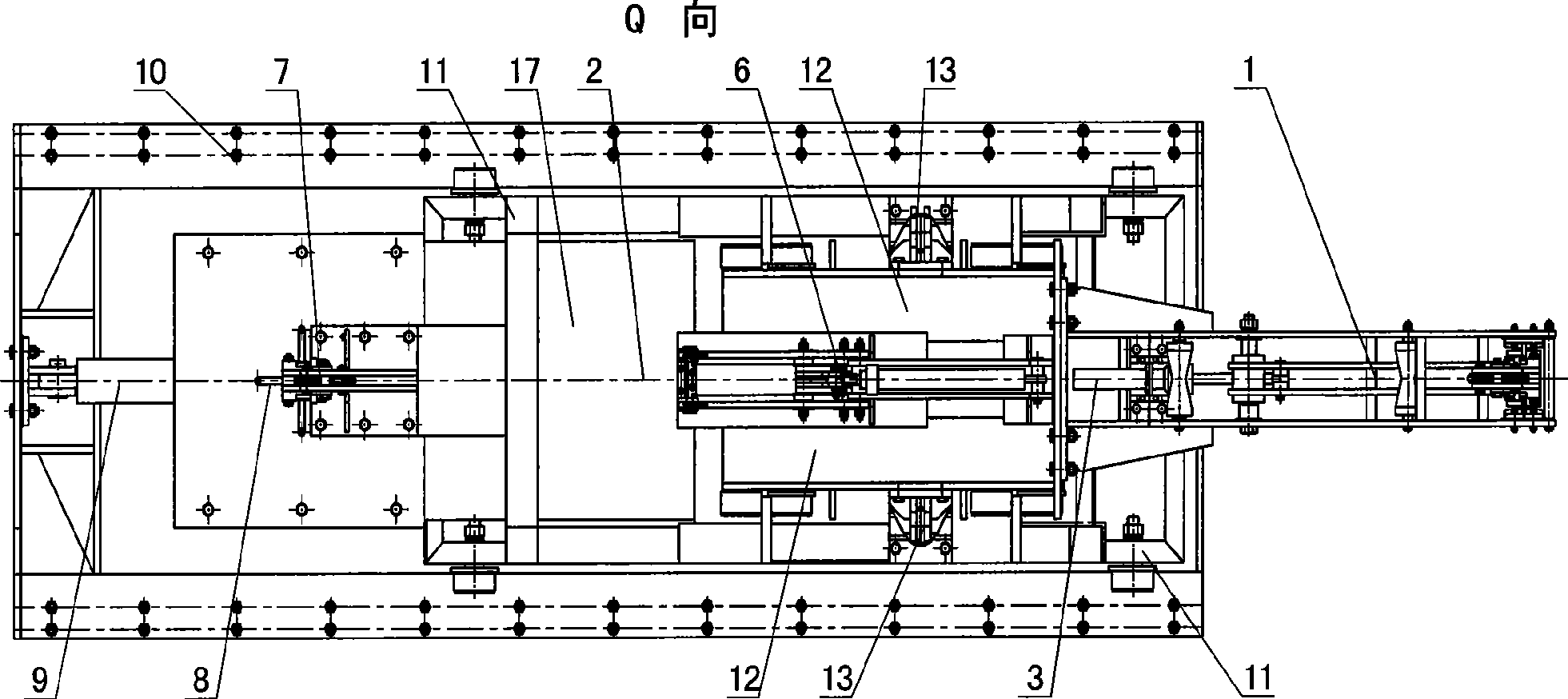

[0012] The embodiment of the present invention "a strip coil automatic bundling machine and bundling method" will be further described in detail below in conjunction with the accompanying drawings: Figure 2 to Figure 5 The big car body 11 of the shown a kind of strip coil automatic bundling machine is placed on the track 10 through the roller, the piston of the oil cylinder 9 is connected with the lower end of the big car body 11, and the tail of the oil cylinder 9 is connected with the left end of the track 10. A small car body 12 is installed in the middle of the big car body 11, the piston of the oil cylinder 13 is connected with the small car body 12, the tail of the oil cylinder 13 is connected with the big car body 11, and the two sides of the small car body 12 are respectively equipped with 4 sets of rollers. Every group has two pairs of rollers, the outer diameters between the two pairs of rollers are in contact with the two sides of the vertical guide rails on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com