Casting-rolling aluminum alloy blank and producing method thereof

A production method and technology of aluminum alloy, applied in the field of aluminum alloy materials, can solve the problems of unclear product performance, unfavorable promotion and application, lack of process parameters, etc., and achieve the effect of improving the quality of the board surface, shortening the production cycle, and improving the production efficiency.

Inactive Publication Date: 2010-08-25

HENAN MINGTAI AL INDUSTRIAL CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The process is more complex and consumes more energy, which is not conducive to popularization and application

The patent document with application number 200710022619.2 discloses a casting and rolling process of 6061 high-strength aluminum alloy plate. The necessary process parameters and the performance of the obtained product are not clear, so the process is difficult to implement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Login to View More

Abstract

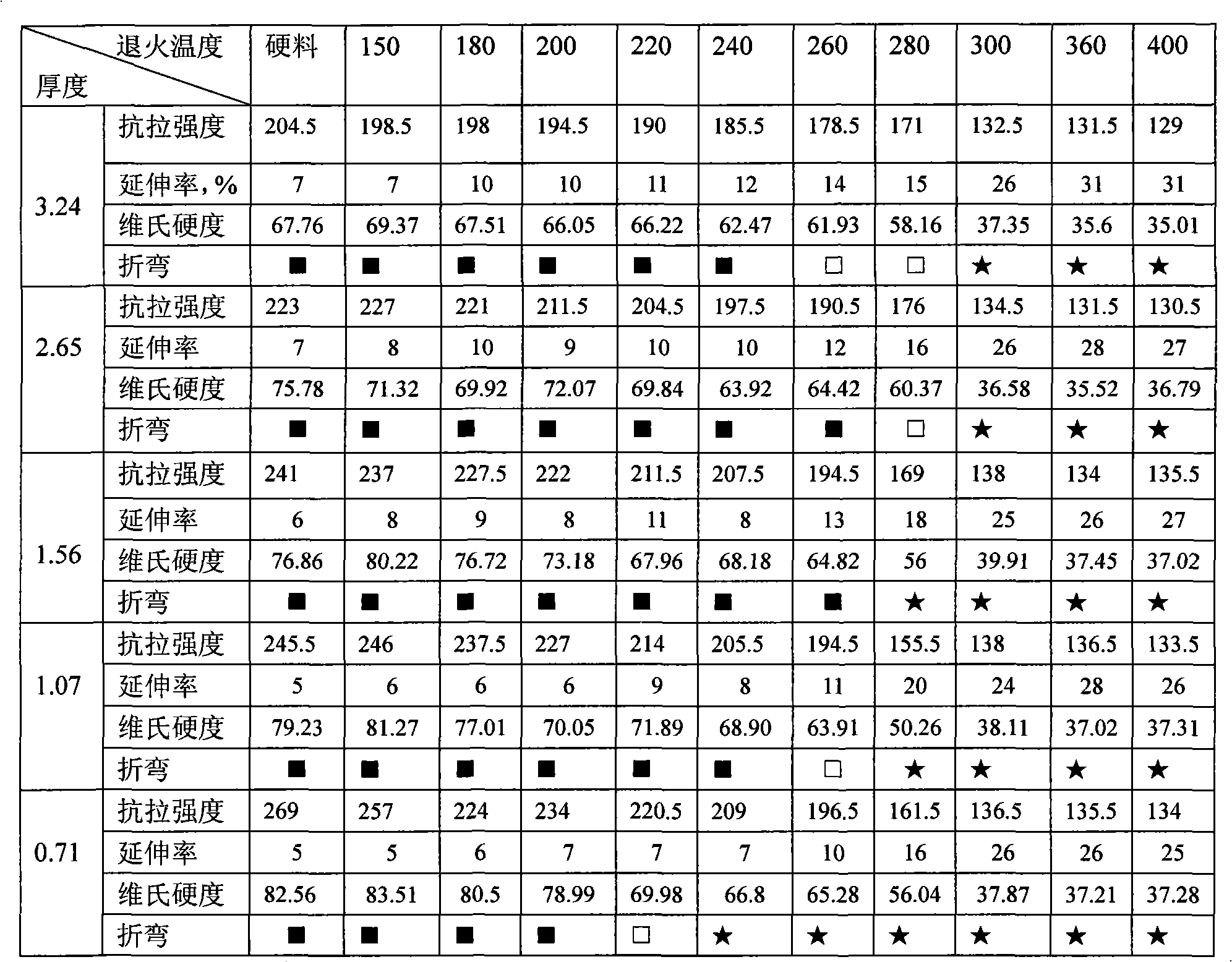

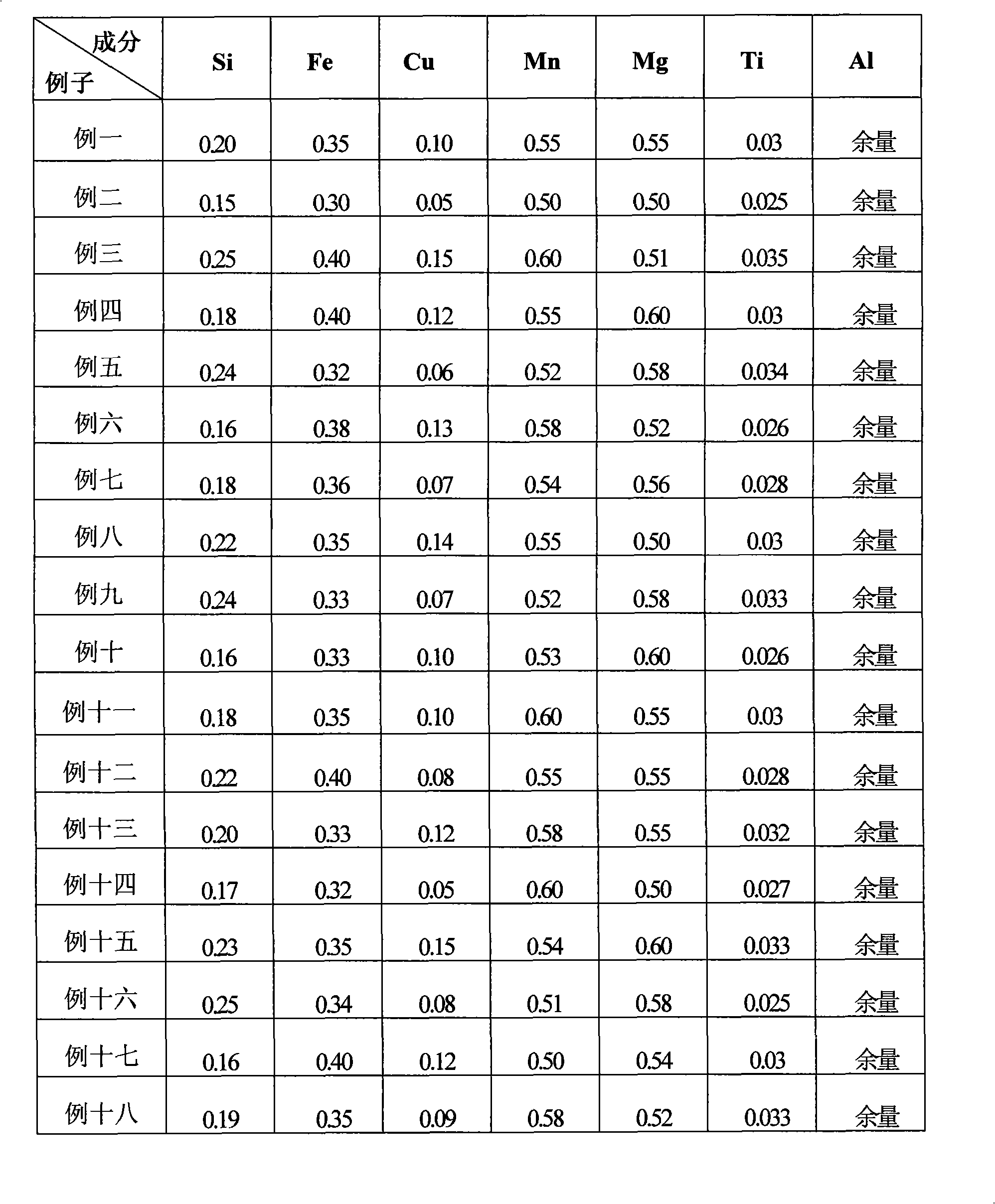

The invention relates to a cast-rolling aluminum alloy blank and a production method thereof. The blank comprises 0.15-0.25 part of Si, 0.3-0.4 part of Fe, 0.05-0.15 part of Cu, 0.5-0.6 part of Mn, 0.5-0.6 part of Mg, 0.025-0.035 part of Ti and the balance of Al, amounting to 100 parts. The production method comprises: aluminum alloy melt is prepared by smelting at the temperature of 750-850 DEG C; a 6.8-7.2mm-thick strip is cast-rolled through the processes of refining, grain refining, on-line deairing, continuous cast-rolling and the like, and then the blank is rolled through strip shape adjusting, cutting and reeling. The strength of the H24 state product of the cast-rolling aluminum alloy blank of the invention is up to 160-180MPa, and the elongation is greater or equal to 8%, the performance of the product is stable and the quality meets the national standard; the method is simple and a plurality of production processes in the traditional method are saved, thus the production period is evidently shortened; the consumption of raw materials and energy is reduced, thus facilitating energy saving and emission reduction and increasing the production efficiency. Therefore, the product has comparatively good economic and social benefits.

Description

1. Technical field: The invention relates to an aluminum alloy material, in particular to a cast-rolled aluminum alloy blank and a production method thereof. 2. Background technology: The production of aluminum alloy blanks can be made by hot rolling or continuous casting and rolling, and then rolled by cold rolling. At present, domestic manufacturers mostly use hot-rolled blanks for production. The hot-rolled blanks process needs to go through production processes such as ingot casting, milling, soaking, and hot rolling. The process is relatively cumbersome, the production cost is high, and the production efficiency is low; Medium billets are prone to problems such as peeling, scratches, streaks and foreign matter rolling in, and the quality of the board surface is not high. After searching, the invention patent with the application number 200710072126.X discloses an aluminum alloy plate and its production method. During production, the mixture needs to be melted and cast...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C21/08C22C1/02C22C1/06B21B1/46

Inventor 王斌

Owner HENAN MINGTAI AL INDUSTRIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com