Semiconductor sheets and methods for fabricating the same

A semiconductor and sheet technology, applied in the field of semiconductor sheets and their preparation, can solve problems such as solar power system limitations and cost increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Silicon is currently one of the most commonly used semiconductor materials, also known as raw materials, for the preparation of semiconductor wafers. Accordingly, the terms "semiconductor" and "semiconductor material" as used in the present invention refer to silicon-based components and silicon materials. However, as those skilled in the art will readily recognize, other semiconductor materials other than silicon and / or including non-silicon materials can also be prepared using the apparatus and methods of the present invention. Also, although only the use of silicon powder raw material for making silicon flakes is described here, silicon raw material sheets may be used without departing from the invention.

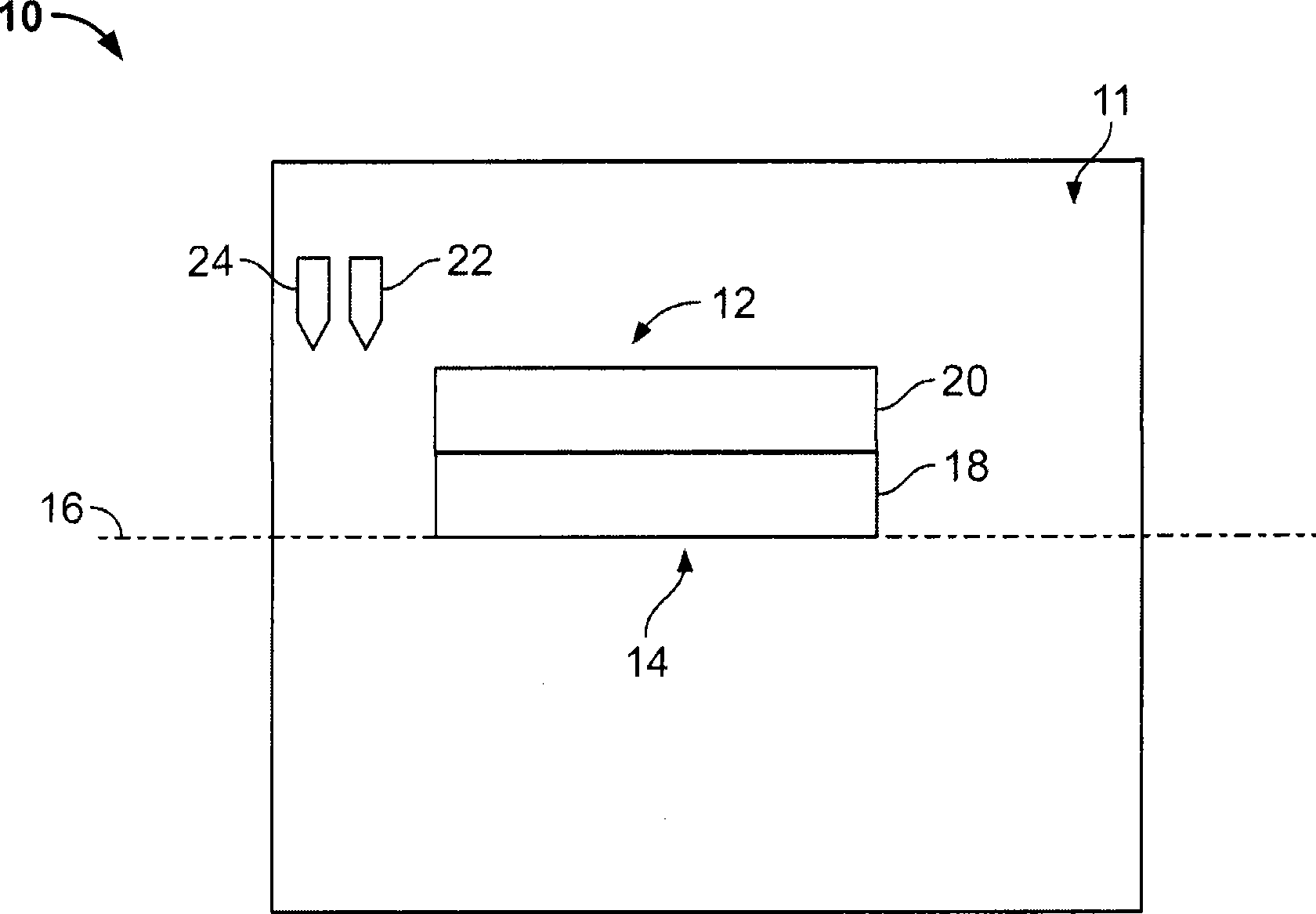

[0013] figure 1 is available for the preparation of silicon flakes (not in figure 1 A schematic diagram of an exemplary embodiment of the furnace apparatus 10 shown in ). The furnace facility 10 includes a controlled atmosphere 11 in order to prevent inert subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com