Oppose-unite engine

A technology of unity of opposites and engine, applied in the direction of machine/engine, mechanical equipment, etc., can solve the problems of large mechanical consumption, large crankshaft stroke, large vibration and noise, etc., to achieve the effect of low mechanical consumption, high efficiency ratio and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

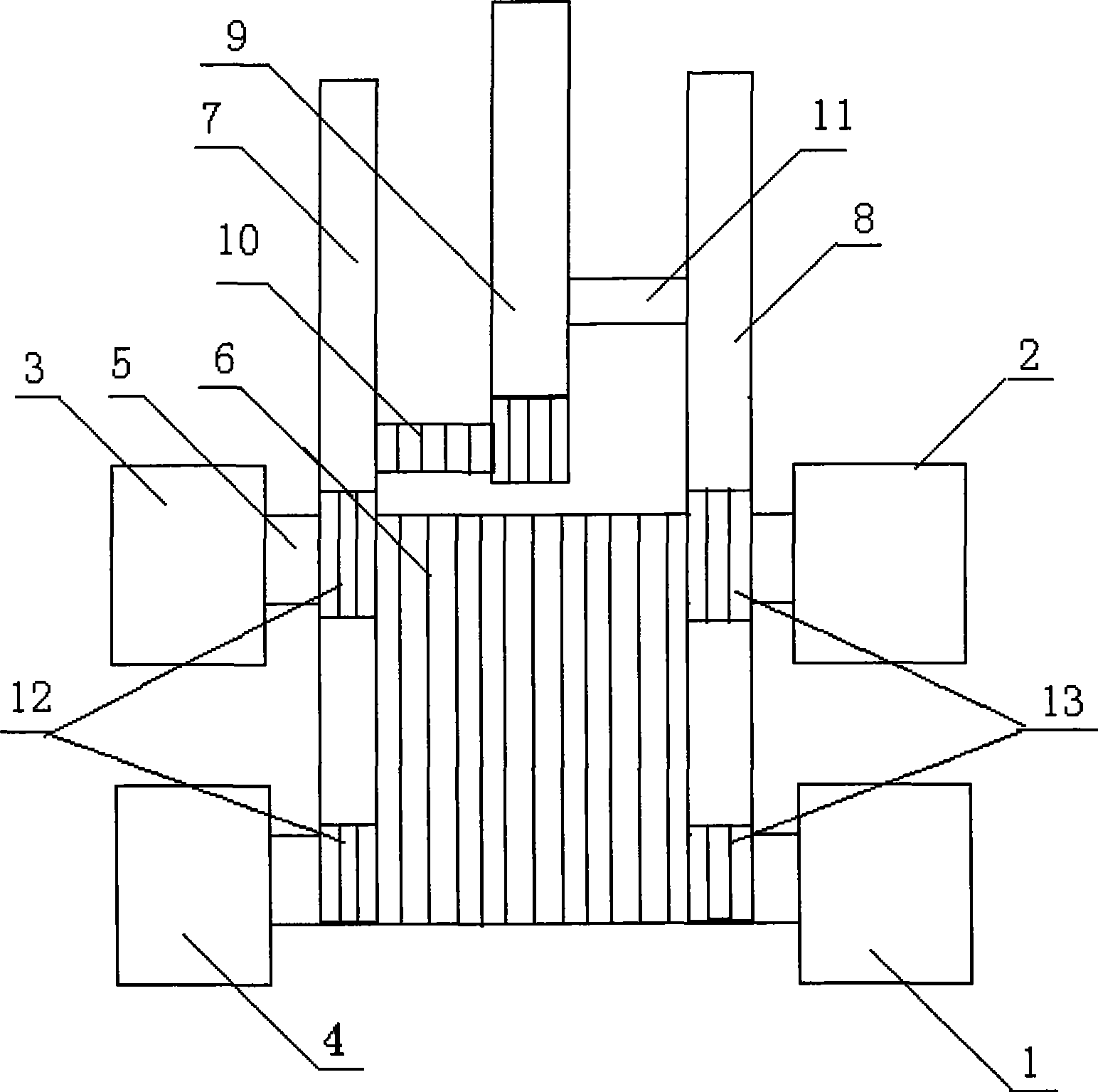

[0010] Such as figure 1 As shown, including No. 1 to No. 4 cylinders 1, 2, 3, 4, left and right stroke output shafts 7, 8 and power output shaft 9, the engine has four cylinders 1, 2, 3, 4, and the pistons of the cylinders are connected together. A piston rod 5, the stroke rack 6 is distributed on the piston rod 5, the left stroke output shaft 7 on the left side meshes with the stroke rack 6 through the same direction reverse gear 12, and the right stroke output shaft 8 on the right side passes through the same direction The positive rotation gear 13 meshes with the stroke rack 6, and the power output shaft 9 is connected to the left and right stroke output shafts 7, 8 through the transition gear 10 and the transmission belt 11.

[0011] In the opposite-unified generator of the present invention, stroke racks 6 are respectively distributed on the top and bottom of the piston rod 5, and the left and right stroke output shafts 7, 8 are respectively engaged on the up and down str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com