Apparatus for enhancing oil gas mixture in combustion-chamber of engine

A technology of oil-gas mixing and combustion chamber, which is applied to engine components, combustion engines, machines/engines, etc. It can solve the problems of incomplete combustion in engine combustion chambers, achieve the effects of improving atomization, saving fuel consumption, and increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings, but this embodiment is not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention .

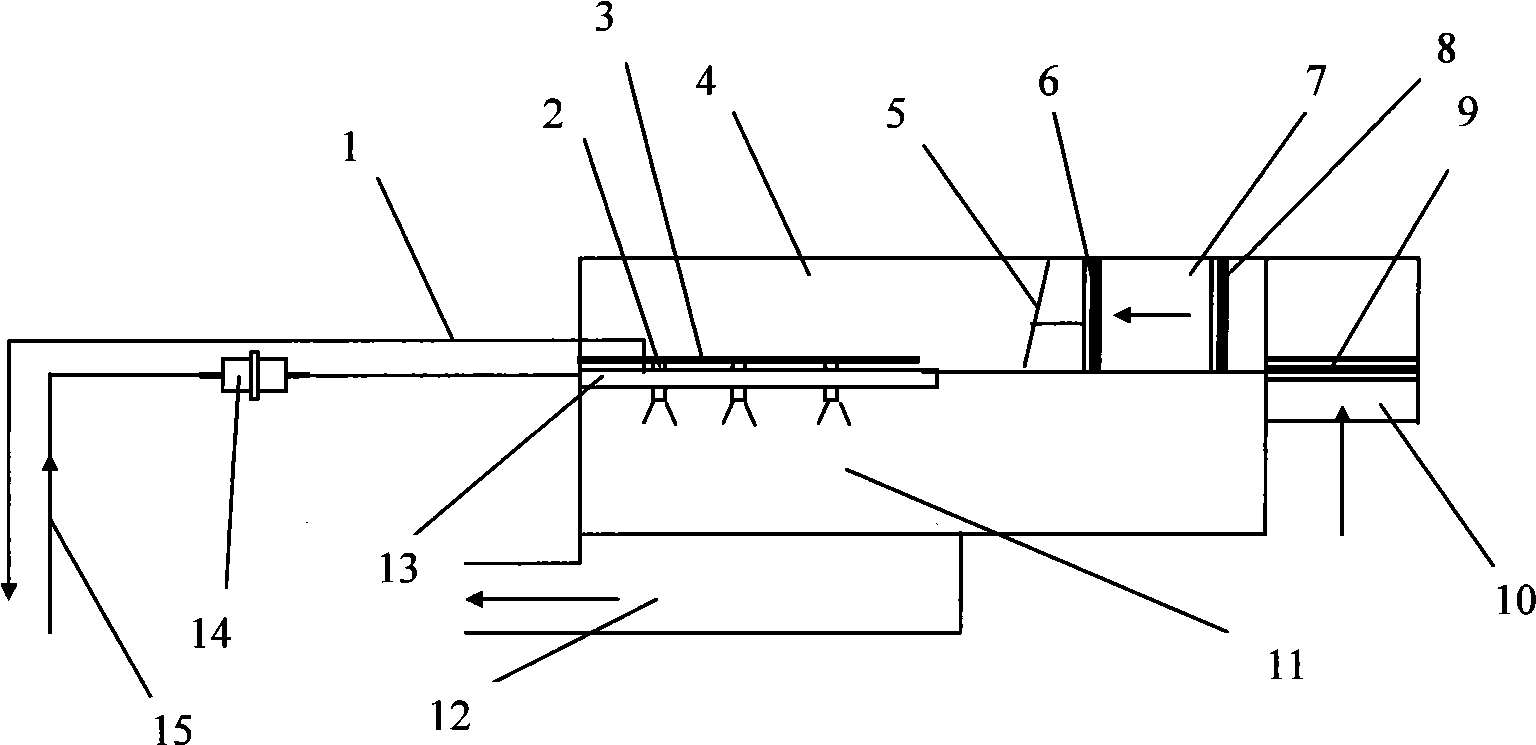

[0014] Such as figure 1 As shown, the device for strengthening the mixing of oil and gas in the engine combustion chamber of the present invention mainly includes oil return pipe 1, nozzle 2, parallel flow divider 3, air cavity 4, choke valve 5, swirler I 6, transition section 7, swirler II 8. Air filter 9, intake port 10, engine combustion chamber 11, exhaust pipe 12, parallel injector 13, magnetizing device 14, oil inlet pipe 15.

[0015] A magnetizing device 14 is installed between the oil inlet pipe 15 and the parallel injector 13, and several nozzles 2 are installed on the parallel injector 13, and the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com