Soft measurement method for billet temperature distribution in smelting and heating-furnace

A technology of temperature distribution and soft measurement, applied in the detection and control of the production process of the steel rolling industry, and the field of metallurgy, it can solve the problems that the temperature distribution cannot be directly measured, and it is difficult to realize the advanced control of the heating furnace and predict the rolling effect of the billet, so as to increase the output. , The effect of improving product quality and high soft measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution details of the present invention will be described in detail one by one below, and the purpose and effect of the present invention will be more obvious.

[0018] The soft sensing method for detecting the temperature distribution of steel slabs in the metallurgical heating furnace of the present invention comprises the following steps:

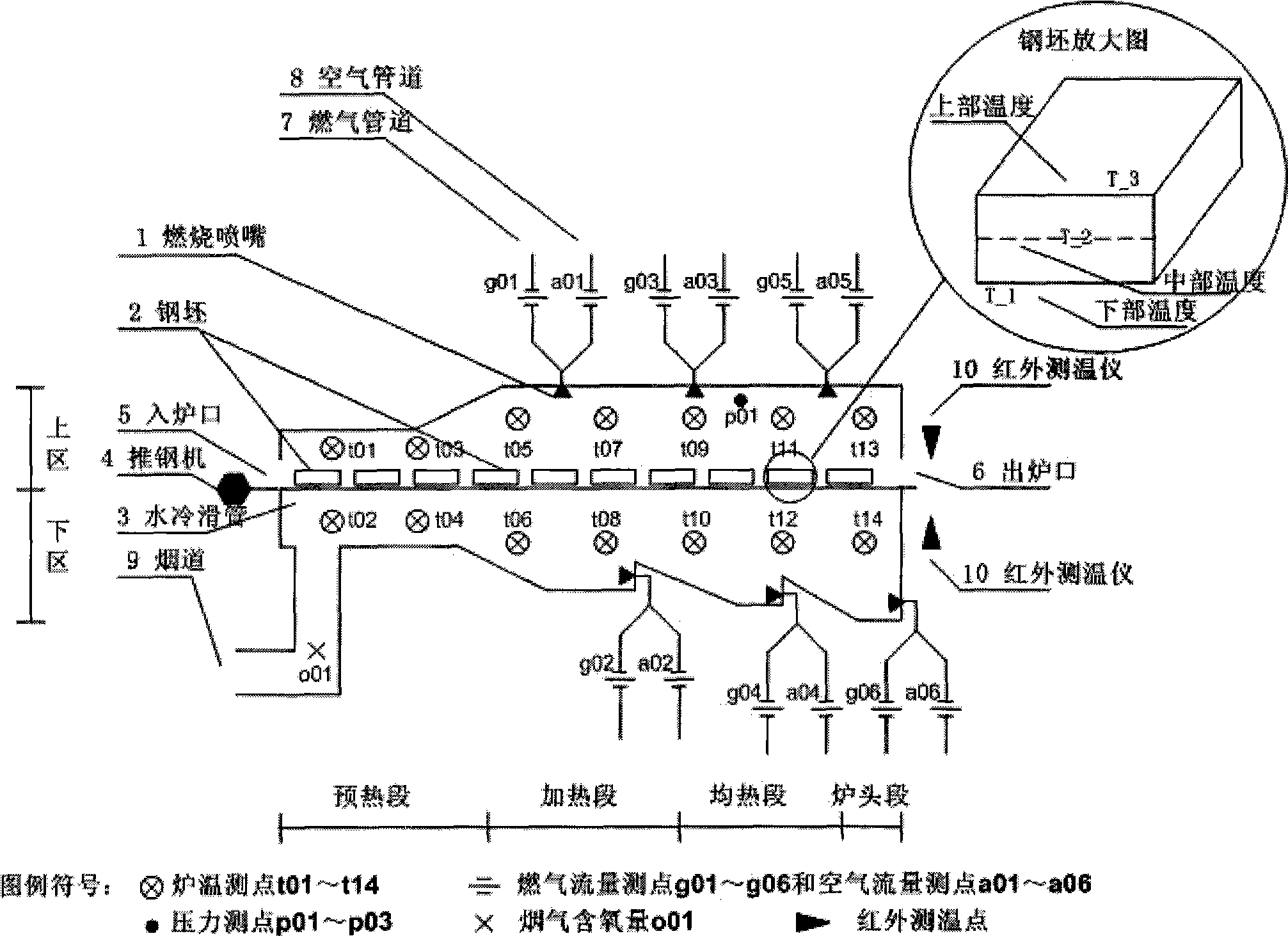

[0019] (1) Select 30 production measurement parameters that have a direct impact on the temperature distribution of the billet as auxiliary variables of the soft sensor model to form a measurement parameter vector X m .

[0020] The 30 selected auxiliary variables for production measurement are: temperature t01 in the upper part of the preheating section, temperature t02 in the lower part of the preheating section, two temperatures t03 and t05 in the upper part of the heating section, two temperatures t04 and t06 in the lower part of the heating section, two temperatures in the upper part of the soaking section On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com