Process method for punching inside of automobile inner decorative mould

A technology for automotive interior parts and process methods, applied in the field of in-mold punching technology for automotive interior parts, can solve the problems of low production efficiency, large investment, low product quality, etc., to improve production efficiency, reduce production costs, reduce The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

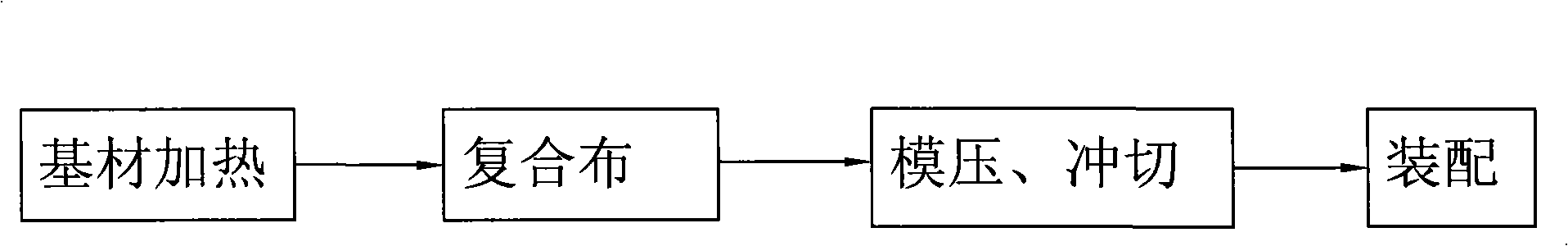

[0009] Definition of in-mold punching: In-mold punching technology for interior parts is a new process technology that realizes simultaneous completion of product forming and punching trimming by adding a floating shear knife in the forming mold. Mainly during the production process of molding the product, the trimming of the product and the punching of the forming hole are completed at the same time. The generally used molding materials are thermoplastic materials, such as PP hemp felt board, PP wood powder board, etc.

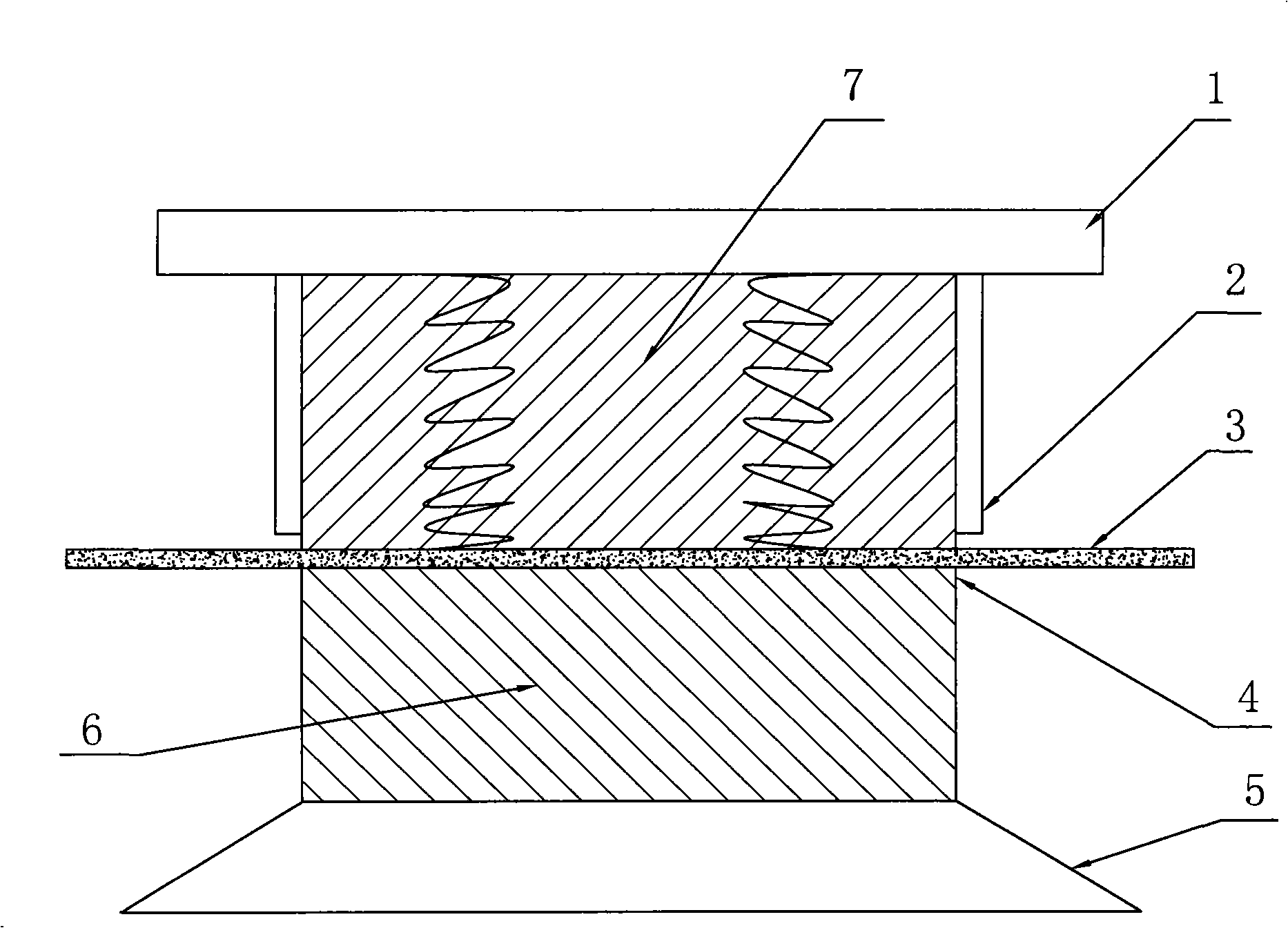

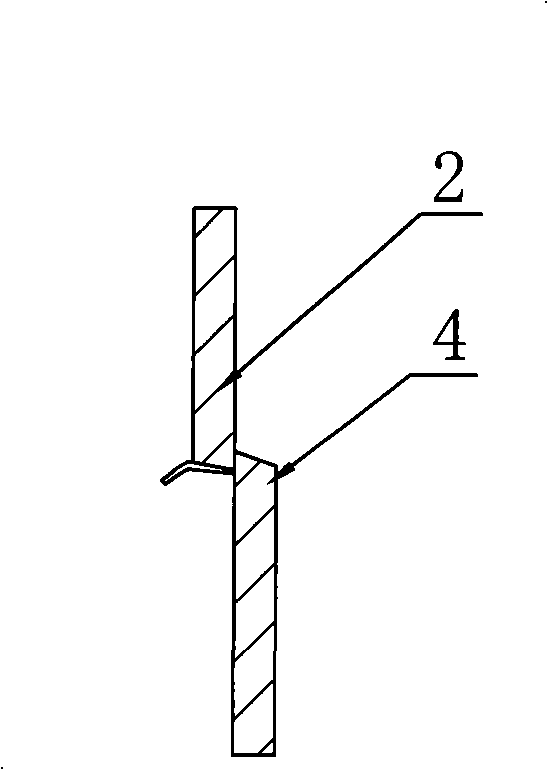

[0010] to combine figure 1 , 2 , 3 shows the description of the present invention as follows:

[0011] Such as figure 1 As shown, the compression molding mold includes an upper template 1, a lower template 5, an upper mold 7 installed on the upper template 1, a lower mold 6 installed on the lower template 5, and an upper mold 7 and a lower mold 6 of the compression molding mold A punching hole device is added, and a floating shearing knife edge trimming de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com