Method for controlling power limit load of caterpillar crane

A crawler crane, power limit technology, applied in the direction of engine control, load suspension components, mechanical equipment, etc., can solve the problems that affect the service life of the engine, the impact of the hydraulic system is large, and the engine is easy to stall, so as to protect from impact and prolong the life of the engine. The effect of long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

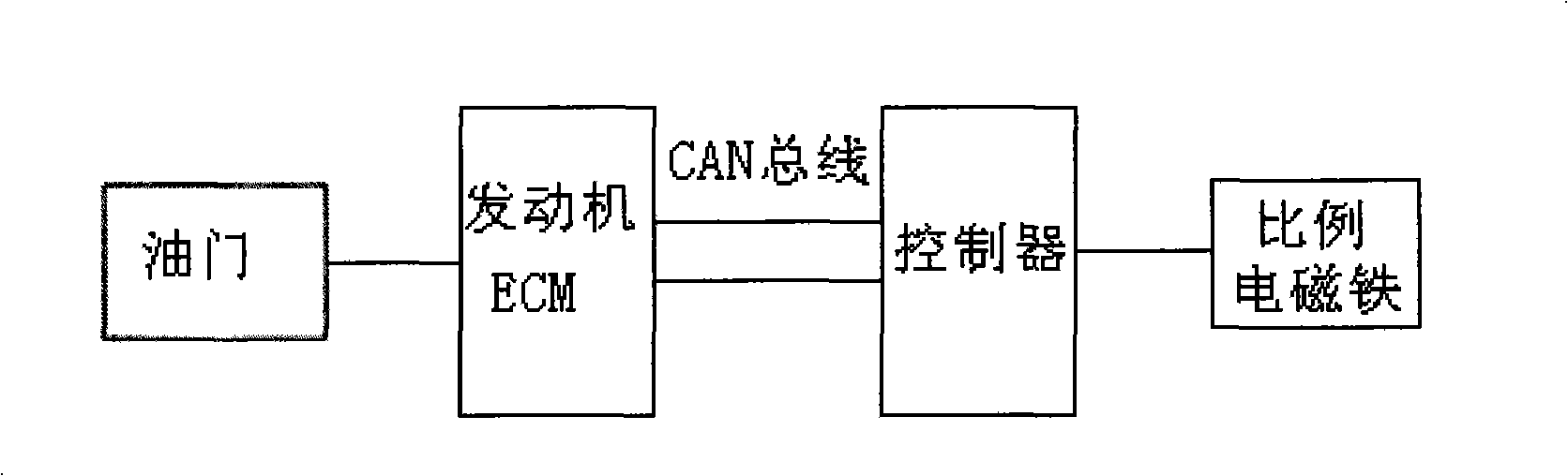

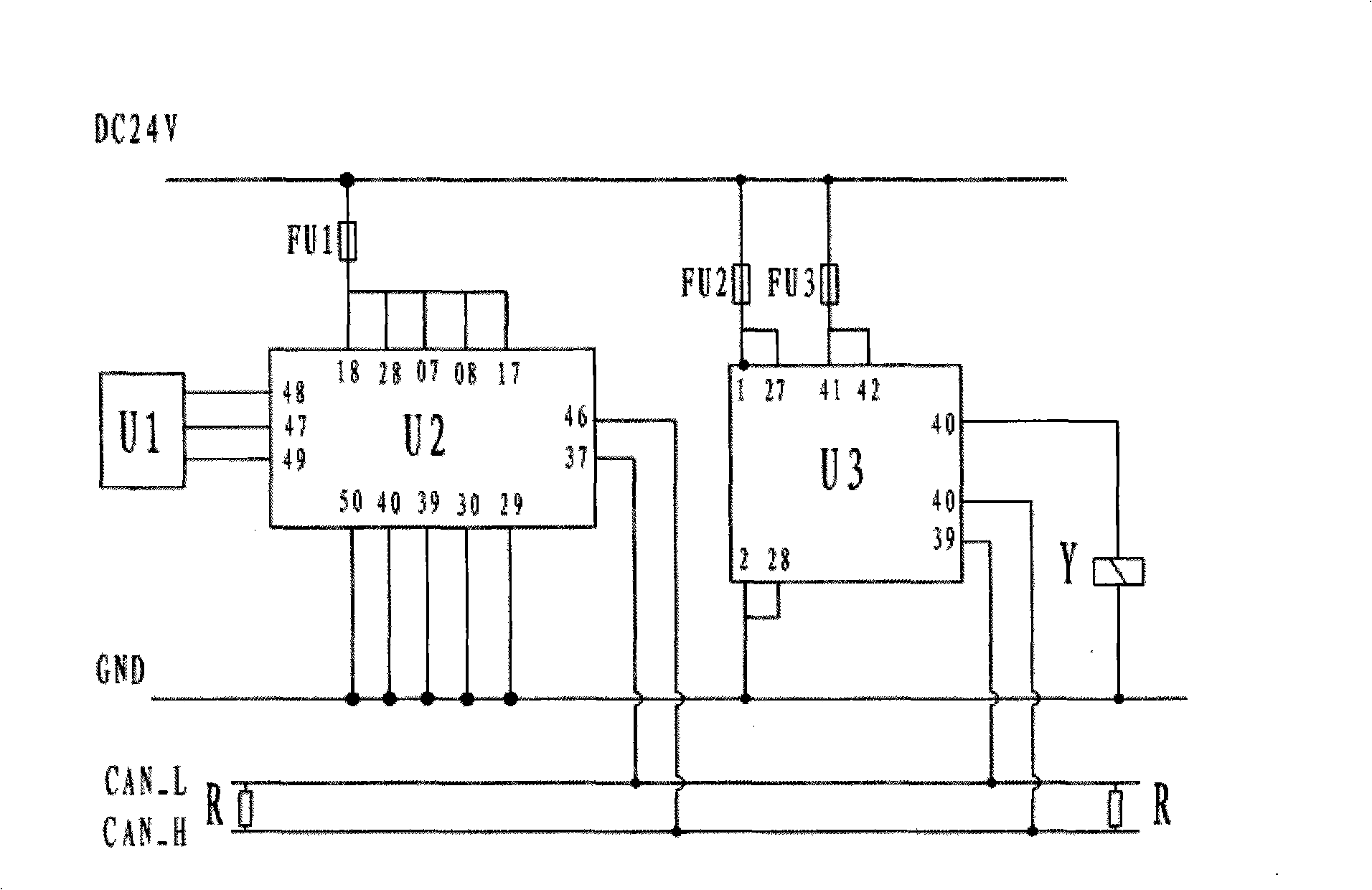

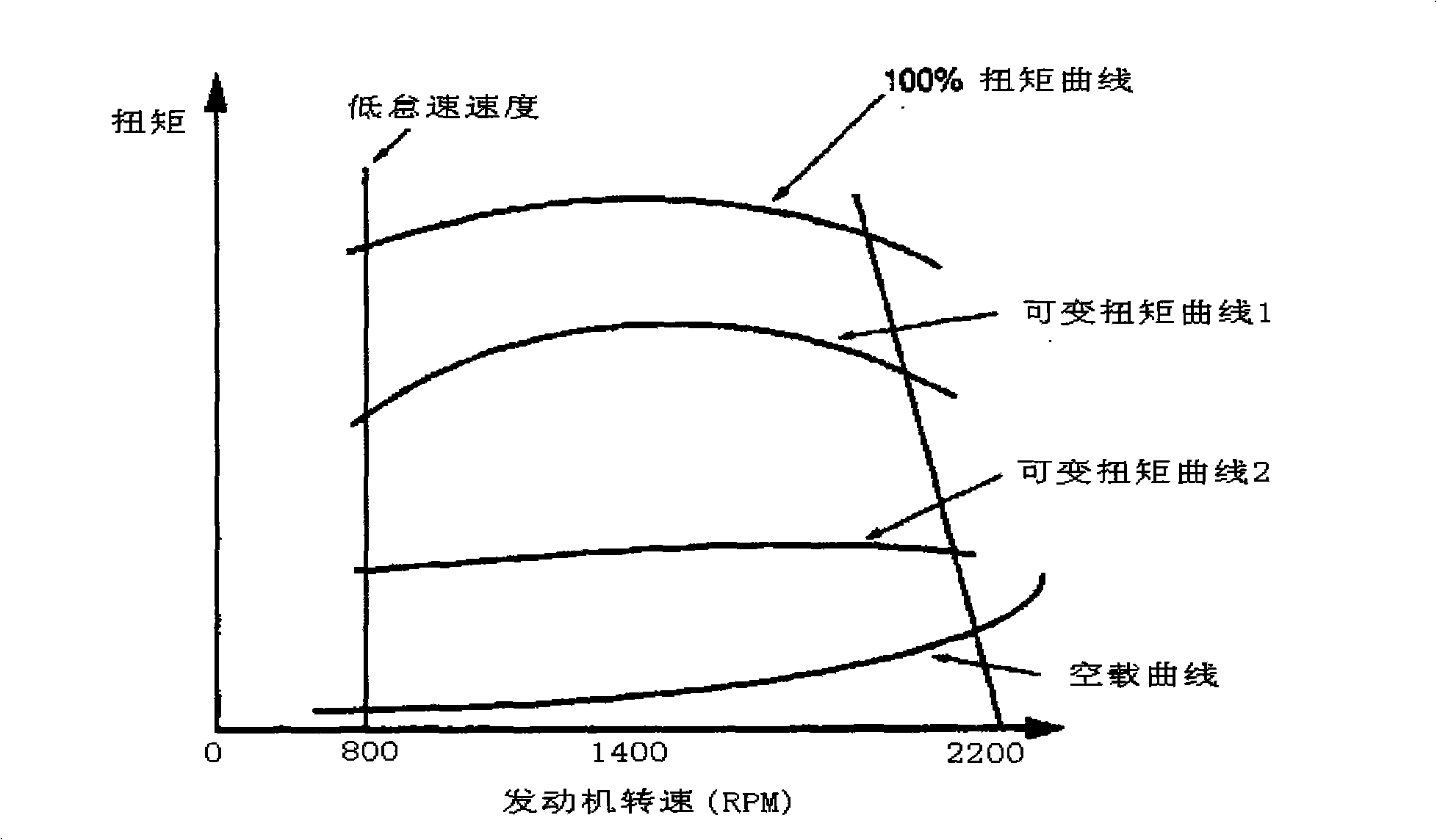

[0012] The present invention will be further described below in conjunction with the accompanying drawings. figure 1 It is a structural block diagram of the present invention, including a proportional electronically controlled hydraulic pump A8VO140LA1H2, a proportional electromagnet used to control the swing angle of the hydraulic pump, a controller used for data acquisition and PID adjustment, and an ECM on the EFI engine.

[0013] The pedal accelerator in the cab is connected to the accelerator input port of the engine ECM, and the engine ECM is connected to the controller in the electric control cabinet through the CAN bus, and the function is that the controller receives the data of the engine through the CAN bus. The proportional electromagnet on the hydraulic pump is connected to the PWM proportional output port of the controller RC6-9. The function is to control the opening size of the proportional solenoid valve through the output port of the controller, and then contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com