High-luminance LED illuminating energy-saving lamp with round luminous spots and electric torch

A high-brightness, energy-saving lamp technology, applied in lighting devices, lighting and heating equipment, portable lighting devices, etc., can solve the problems that cannot be used to make screw lamps, bayonet lamps, cannot produce, and uneven illumination , to achieve the effect of improving light efficiency and output power, long life, and uniform illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

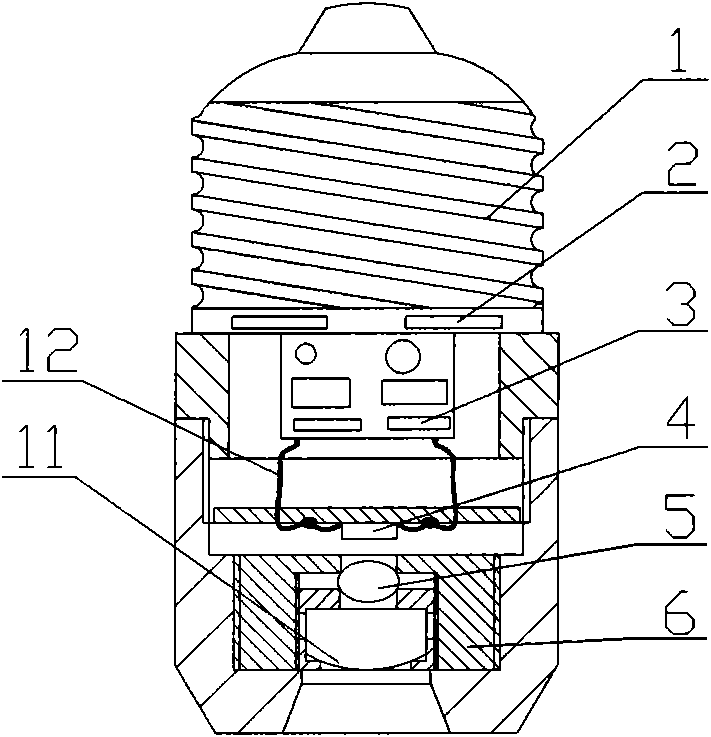

[0015] Embodiment 1: with reference to attached figure 1 . High-brightness LED circular spot lighting energy-saving lamps. The power converter 3 converts AC power into DC low voltage and is located in the housing 9 (9 generally refers to the housing). There is a heat dissipation window 2 on the housing. The power converter 3 The input terminal is a screw lamp base 1 or a bayonet lamp base, and the output terminal 3 of the power converter is connected to the LED chip 4 through a wire 12, and the LED chip 4 is located in the casing 9. The condenser lens 5 is a convex lens, and one side of the circular spot forming lens 11 is a plane, and the other side is a convex lens. Below the lens 5. The main optical axis of the condenser lens 5 and the circular spot shaping lens 11 are located on the same axis, and the illumination window at the lower end of the housing 9 is in the shape of a trumpet 8 . The light spot projected by the lens of the circular spot shaping lens 11 is a circu...

Embodiment 2

[0016] Embodiment 2: On the basis of Embodiment 1, the focal length between the condenser lens 5 and the circular spot shaping lens 11 is adjustable.

Embodiment 3

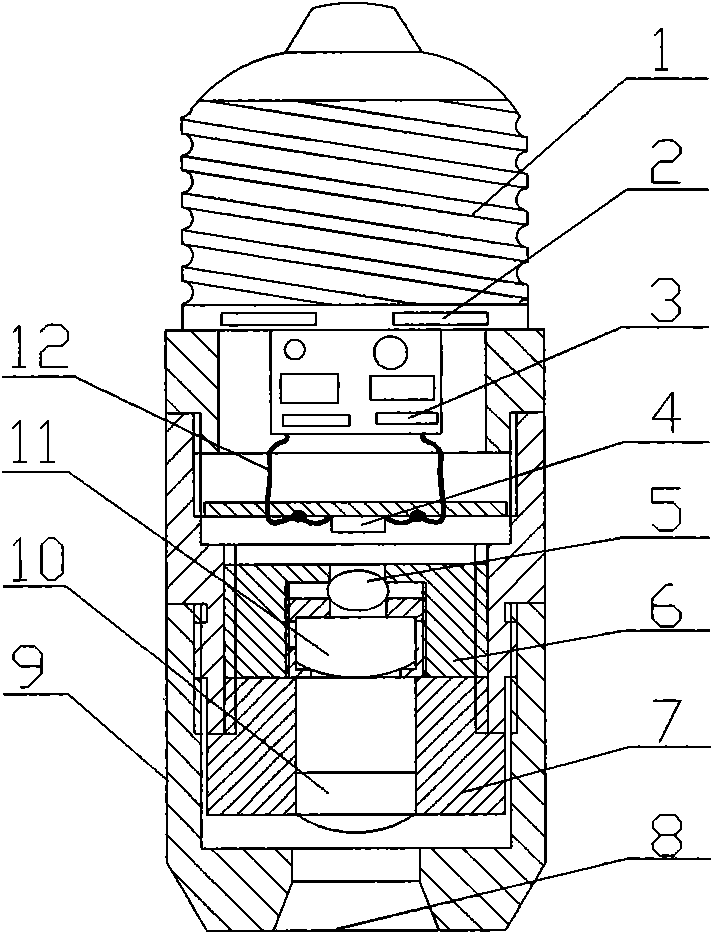

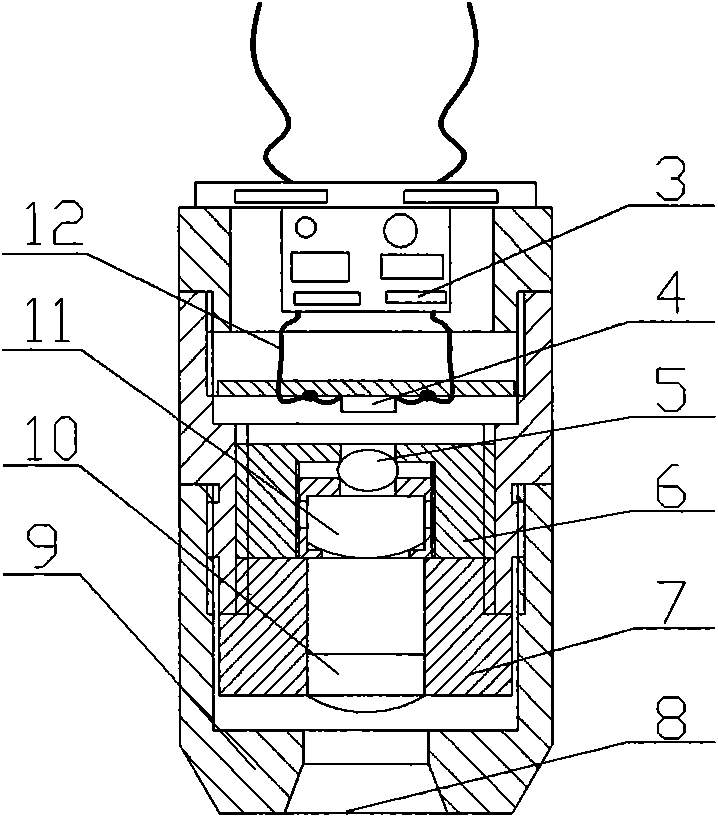

[0017] Embodiment 3: with reference to attached figure 2 . Embodiment 1: with reference to attached figure 1 . High-brightness LED circular spot lighting energy-saving lamps. The power converter 3 converts AC power into DC low voltage and is located in the housing 9 (9 generally refers to the housing). There is a heat dissipation window 2 on the housing. The power converter 3 The input terminal is a screw lamp base 1 or a bayonet lamp base, and the output terminal 3 of the power converter is connected to the LED chip 4 through a wire 12, and the LED chip 4 is located in the casing 9. The condenser lens 5 is a convex lens, and one side of the circular spot forming lens 11 is a plane, and the other side is a convex lens. Below the lens 5. The secondary spot shaping lens 10 is located below the circular spot shaping lens 11 through the frame 7 . The main optical axes of the condenser lens 5 , the secondary spot shaping lens 10 and the circular spot shaping lens 11 are on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com