Micro-electromechanical vector hydrophone

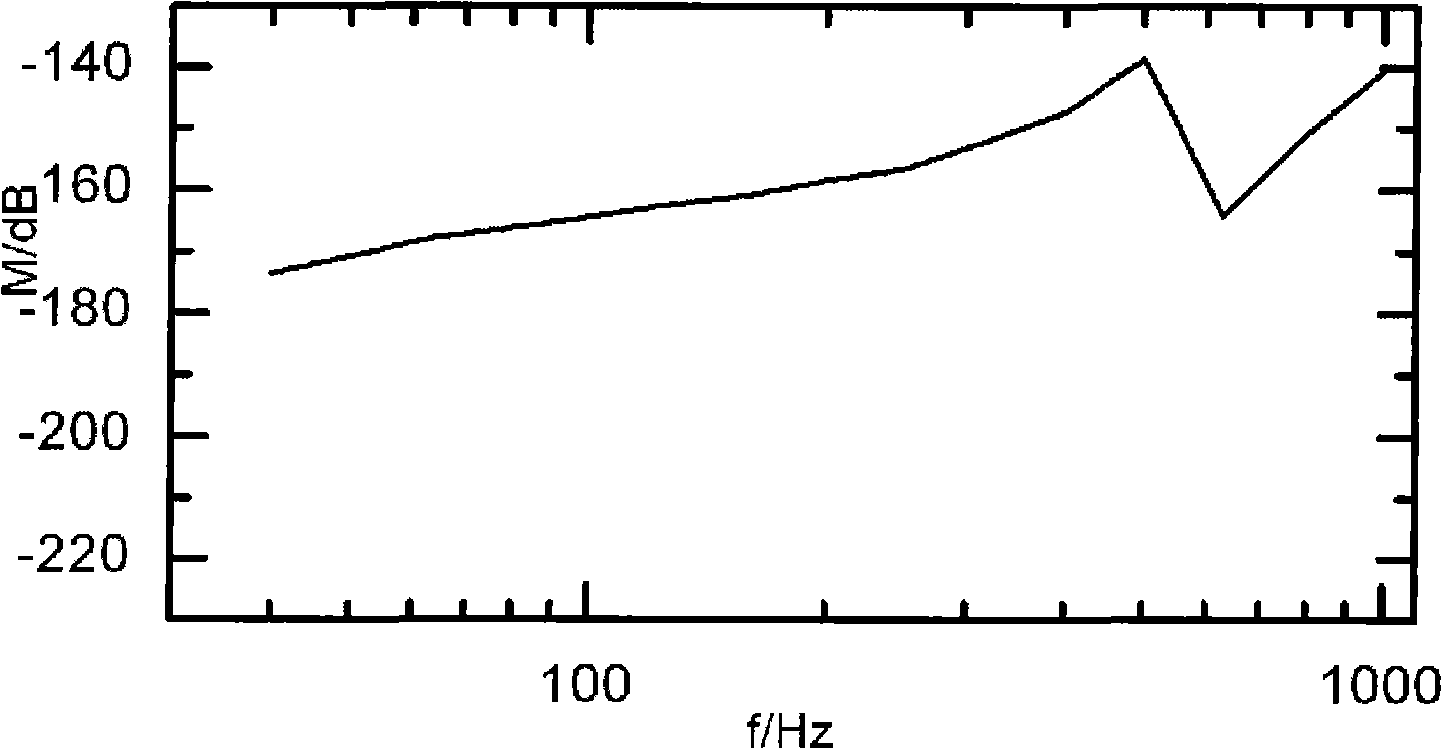

A vector hydrophone, micro-electromechanical technology, applied in radio wave measurement systems, instruments, measurement devices, etc., can solve problems such as overall performance improvement, and achieve the effects of increasing deformation range, reducing monitoring errors, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

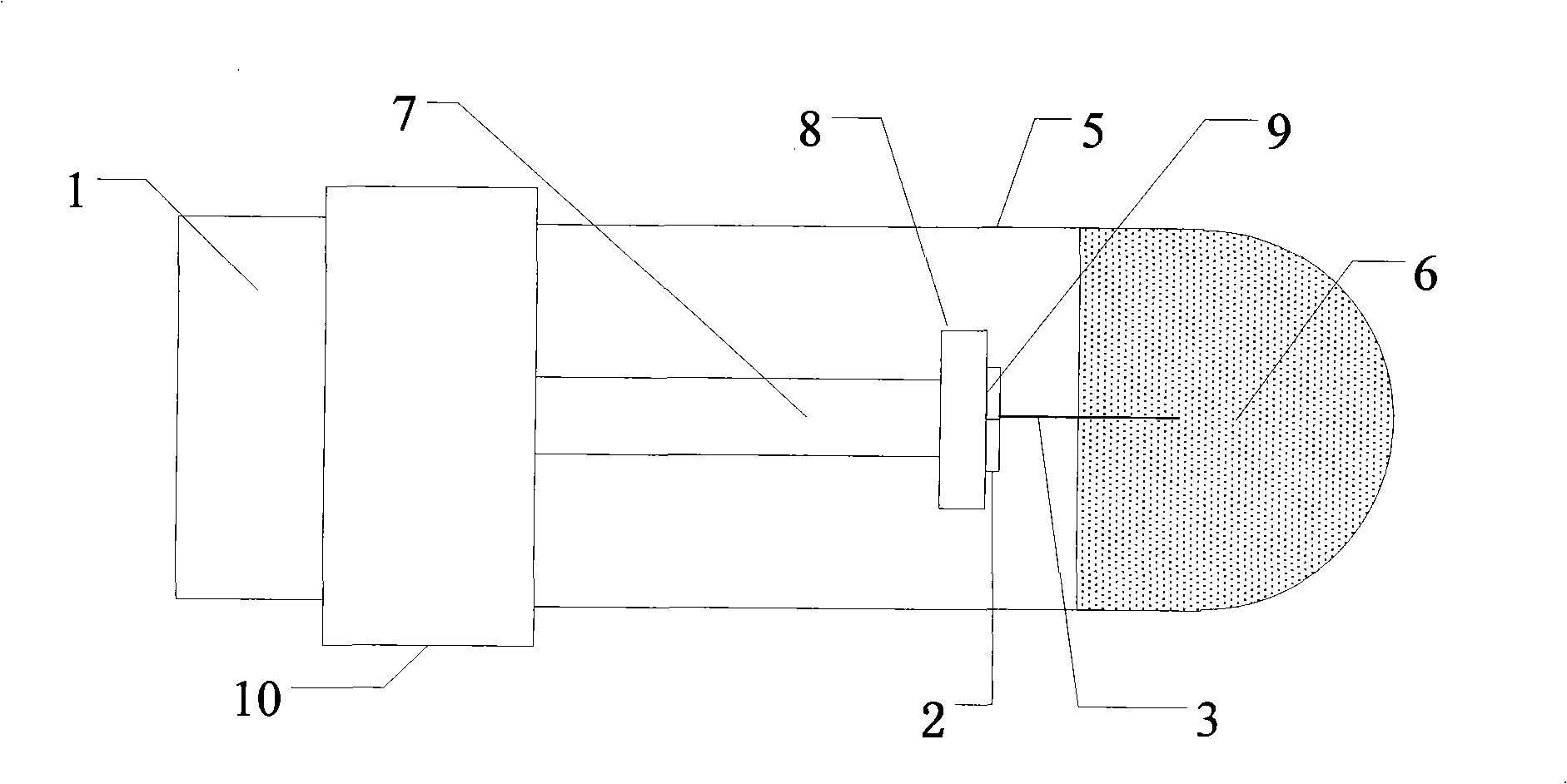

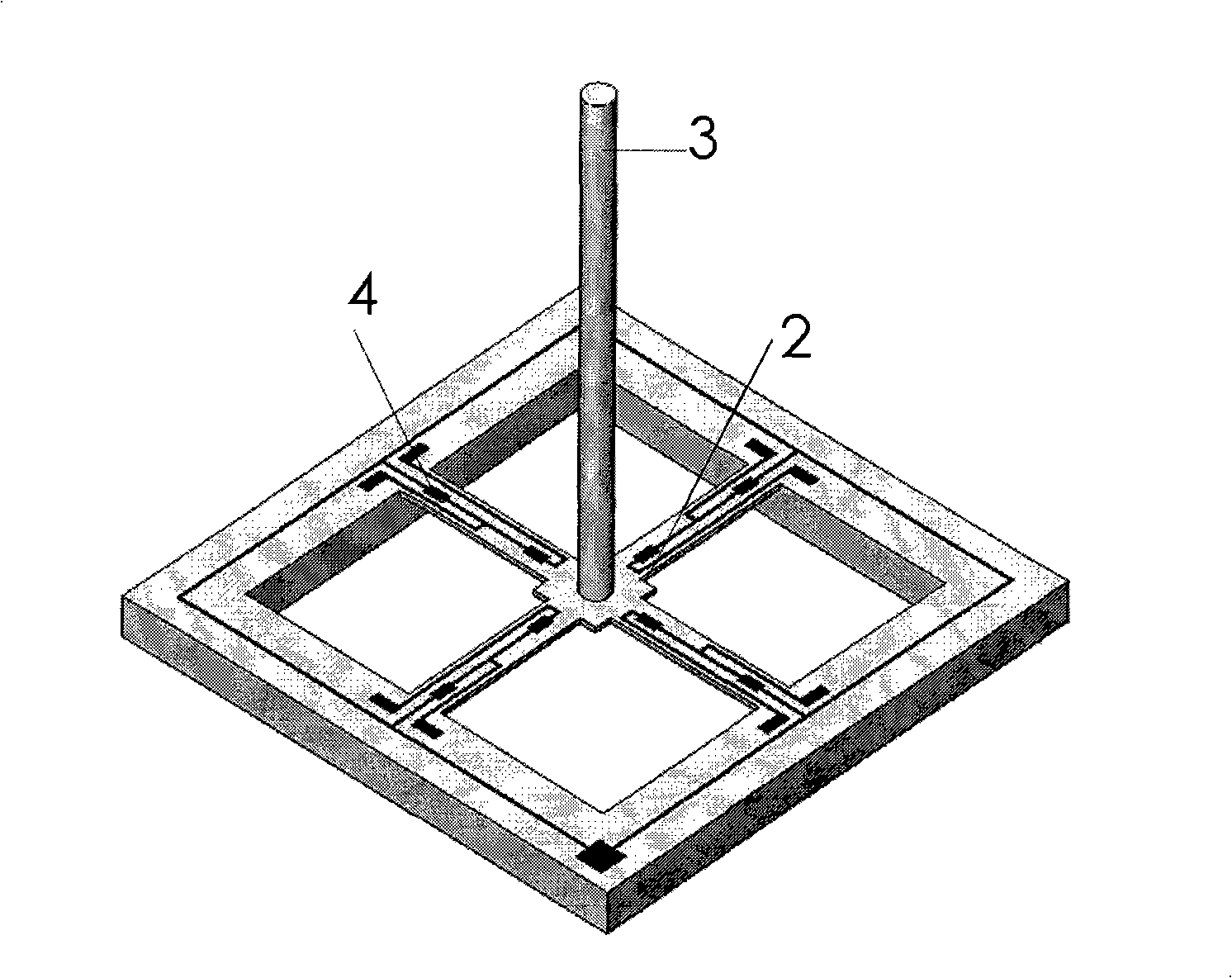

[0018] The microelectromechanical vector hydrophone includes a sensitive conversion microstructure, a support for fixing the sensitive conversion microstructure 1, a package shell that covers the sensitive conversion microstructure and is sealed and fixed with the support 1, the sensitive conversion microstructure is contained in The middle part of the semiconductor substrate is etched into a cross-shaped cantilever beam structure 2 with a density similar to that of water. The micro-column body 3 is vertically fixed in the center of the cross-shaped cantilever beam structure 2. The four-beam end of the glyph cantilever beam structure 2 is provided with a conversion element 4, and the packaging shell is a sound-transmitting rubber cap 5 made of a polyurethane potting material with high frequency, low attenuation and low water permeability through an acoustic potting process. The top of the acoustic rubber cap 5 is potted with polyurethane 6 which fixes the top of the micro-column 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com