Braking controlling method for point-to-point position servo of induction machine

A braking control, induction motor technology, applied in motor generator control, motor/generator/inverter limiter, control system, etc., can solve problems such as overheating, inverter overcurrent, enlargement, etc. Improve braking efficiency, ensure positioning accuracy, improve rapidity and braking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The purpose and effects of the present invention will become more apparent by referring to the accompanying drawings in detail of the present invention.

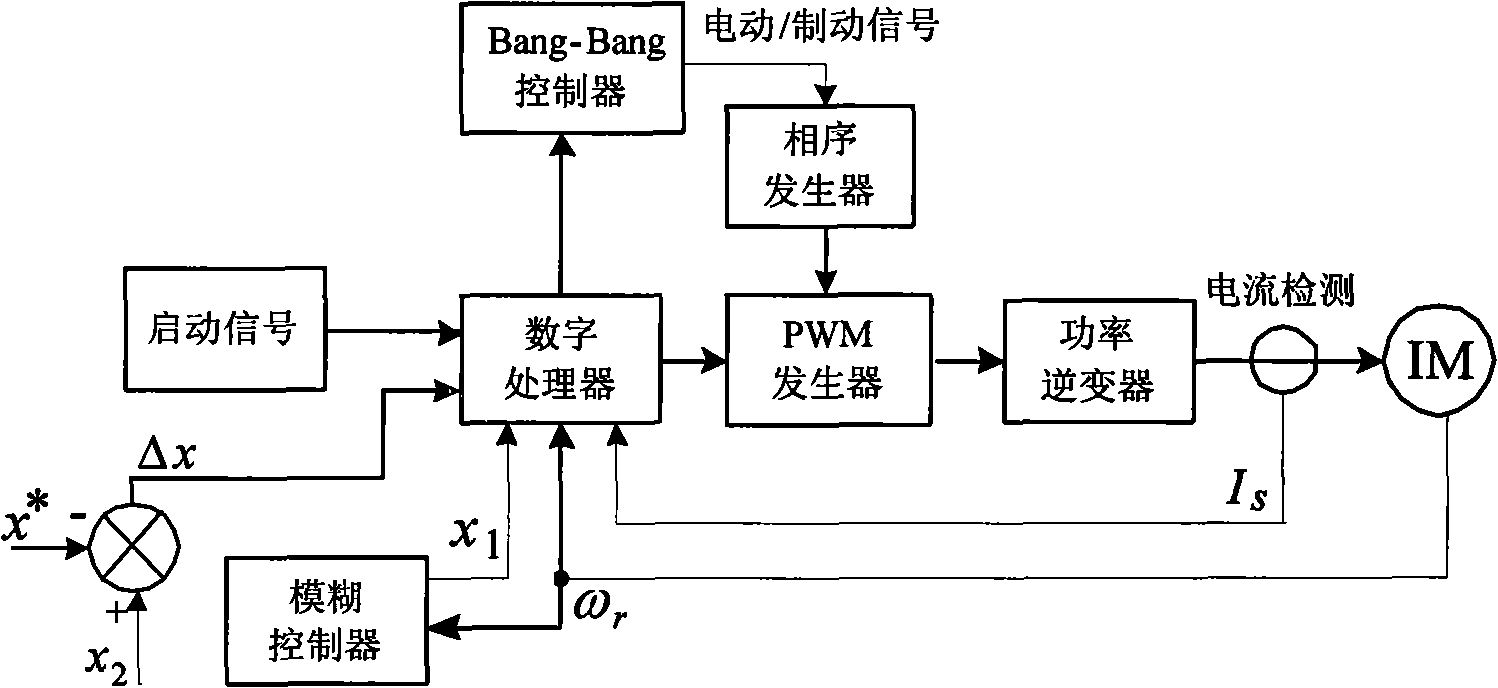

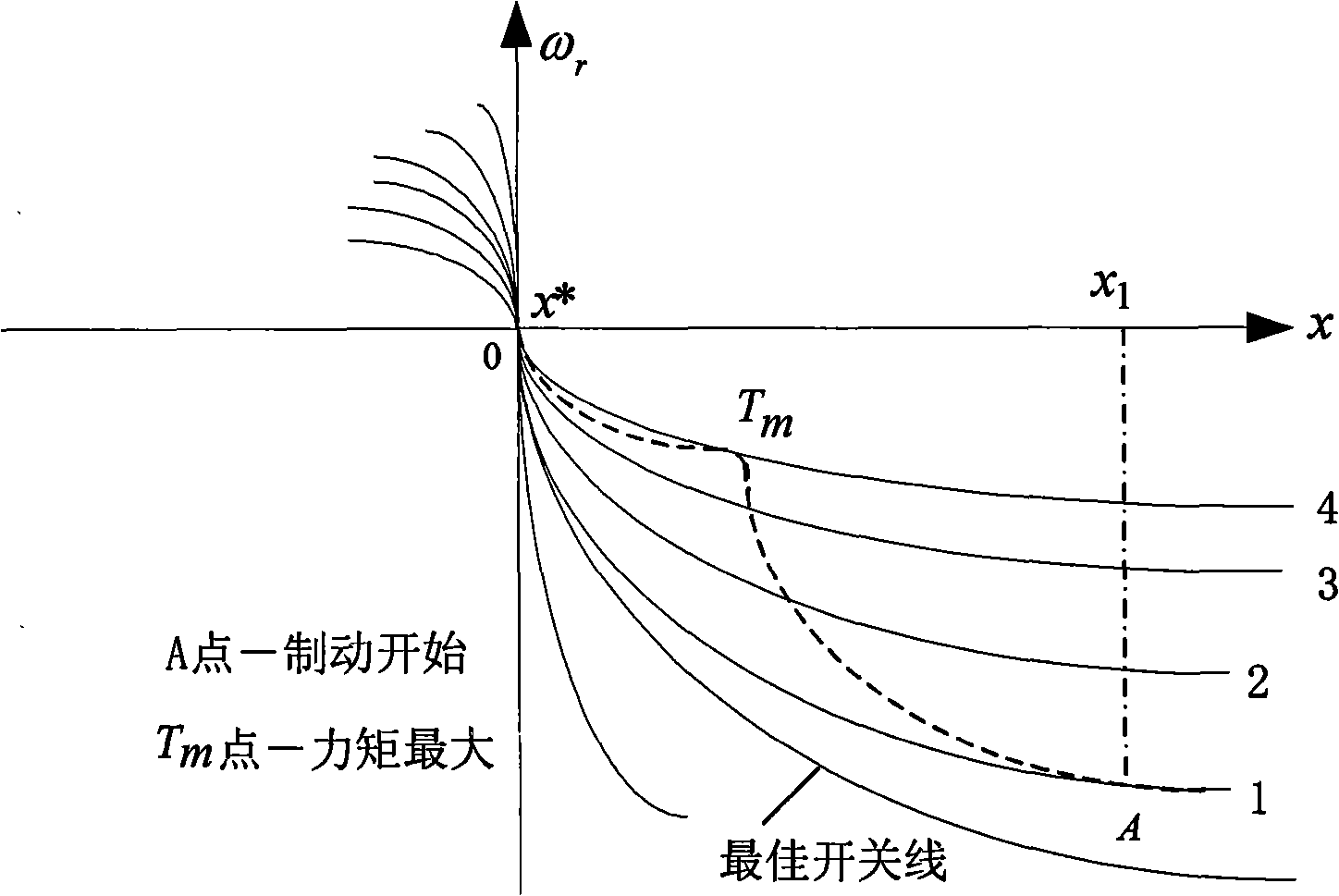

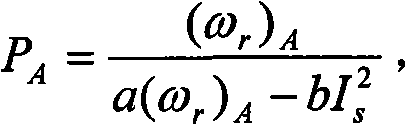

[0019] The core of the present invention is the displacement coordinate x of the controlled moving object reaching the state switch of the control amount 1 , the brake control system brakes the induction motor, and the output size and rotor speed ω in each closed-loop adjustment cycle r Variable stator braking current I with a certain functional relationship s , so that the energy consumption braking phase trajectory of the induction motor avoids converging to the coordinate origin along a certain optimal switch line cluster (that is, the target displacement coordinate x * ), see figure 2 , so as to complete the servo positioning precisely and efficiently in the shortest time. The concrete realization of the present invention carries out by following induction motor energy consumption braking phase locus equation: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com