Foam sheet of thermoplastic resin composition and process for producing the same

A thermoplastic resin and resin composition technology, applied in transportation and packaging, thin material processing, mirrors, etc., can solve the problems of micronized light reflectivity of bubbles that are not recorded and taught, and cannot obtain sufficient light reflection characteristics, etc., to achieve excellent softness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0170] Raw materials: A1, B1, C1, C2, C3

[0171] Dispersion method: Dispersion method※1

[0172] Extruder: ZSK-25 twin-screw extruder

[0173] Screw speed: 300rpm, output: 12kg / hour, resin temperature at die outlet: 290°C

[0174] Under the above conditions, the raw materials of the formula shown in Table 1 were extruded to obtain a PTT composition with a melting point of 225°C.

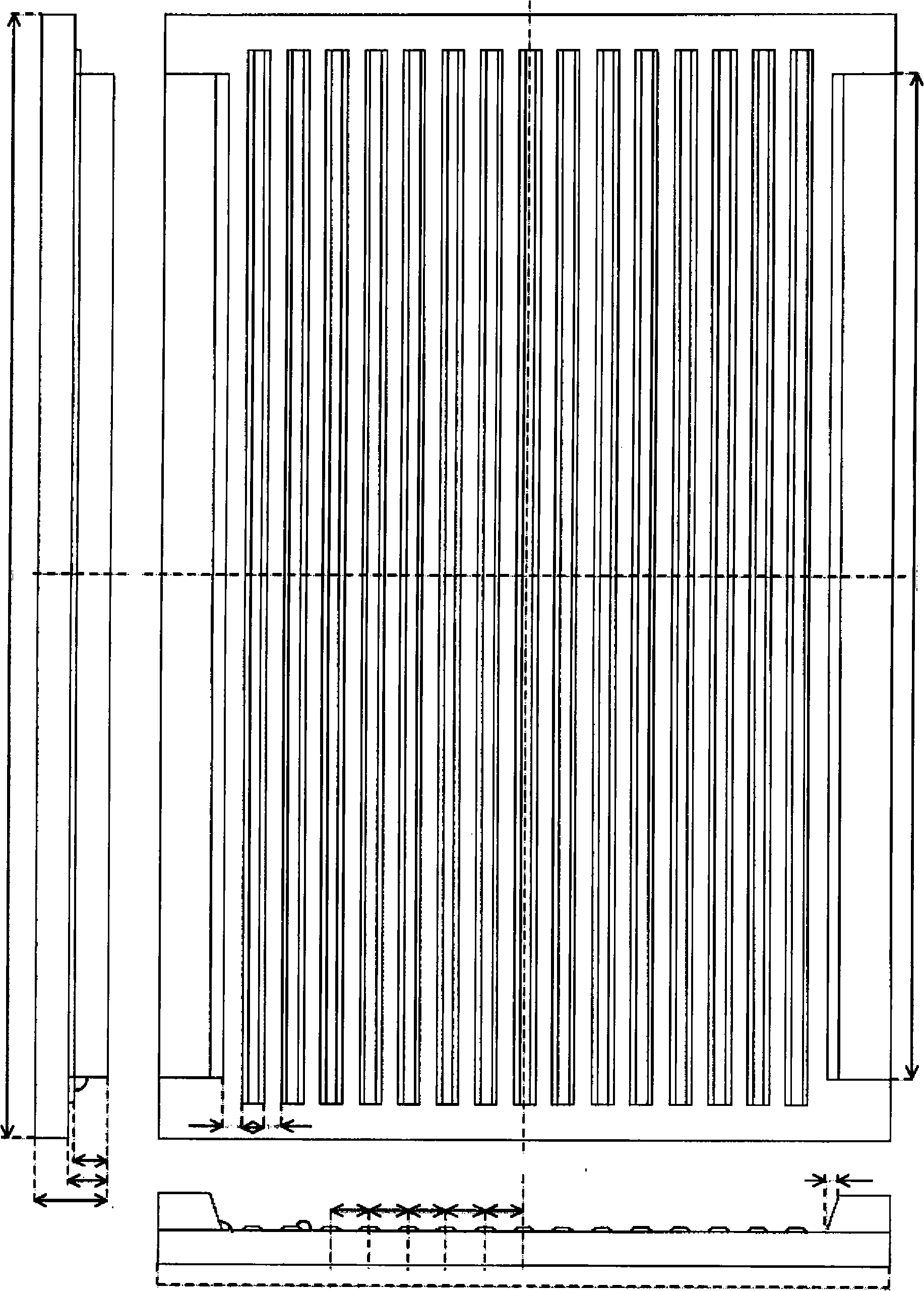

[0175] The aforementioned PTT composition was supplied to a 90mmφ single-screw extruder set at 235°C, melted, and then extruded from a T-die with a width of 1000mm and an interval of 0.6mm as a die at a linear speed of 10m / min. It is sheet-like. The flow path from the extruder to the die is heated to the same temperature as the extruder.

[0176] At this time, 0.1% by weight of nitrogen gas relative to the composition was injected from the center of the extruder, and mixed with the melt and dissolved. In addition, the pressure of the melt at the entrance of the T-die was 15 MPa. The melt extru...

Embodiment 2~4

[0187] Except having changed the compounding quantity of a raw material as shown in following Table 1, it carried out similarly to the said Example 1, and obtained the PTT composition foamed sheet and molded article. The results are shown in Table 1 below. In Examples 2, 3, and 4, sheets having particularly fine cells were obtained. In addition, the value of the apparent density shows that the foamed sheet has light weight and excellent surface appearance. However, some fuzzing was generated on the surface of the sheet in Example 4.

Embodiment 5~7

[0189] Except having changed the amount of nitrogen gas as shown in the following Table 1, it carried out similarly to the said Example 3, and obtained the PTT composition foamed sheet and molded article. The results are shown in Table 1 below. In Examples 5 and 6, sheets having fine cells were obtained. In addition, the value of the apparent density shows that the foamed sheet has light weight and excellent surface appearance. However, some fuzzing was generated on the surface of the sheet in Example 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com