Nippon electric co

A technology of precision alloys and molten metals, which is applied in the field of precision alloys for die casting and precision alloys for die casting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

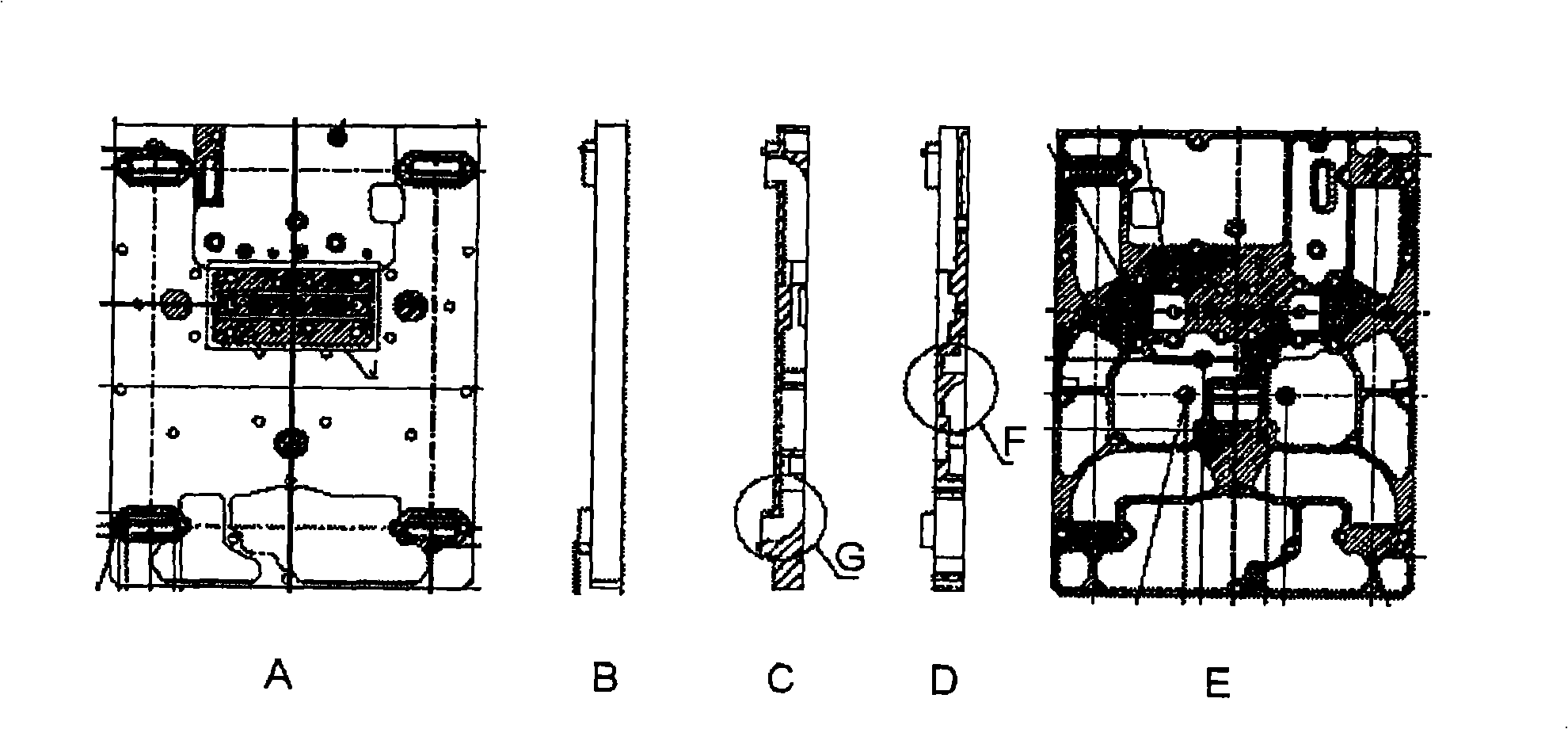

Image

Examples

Embodiment

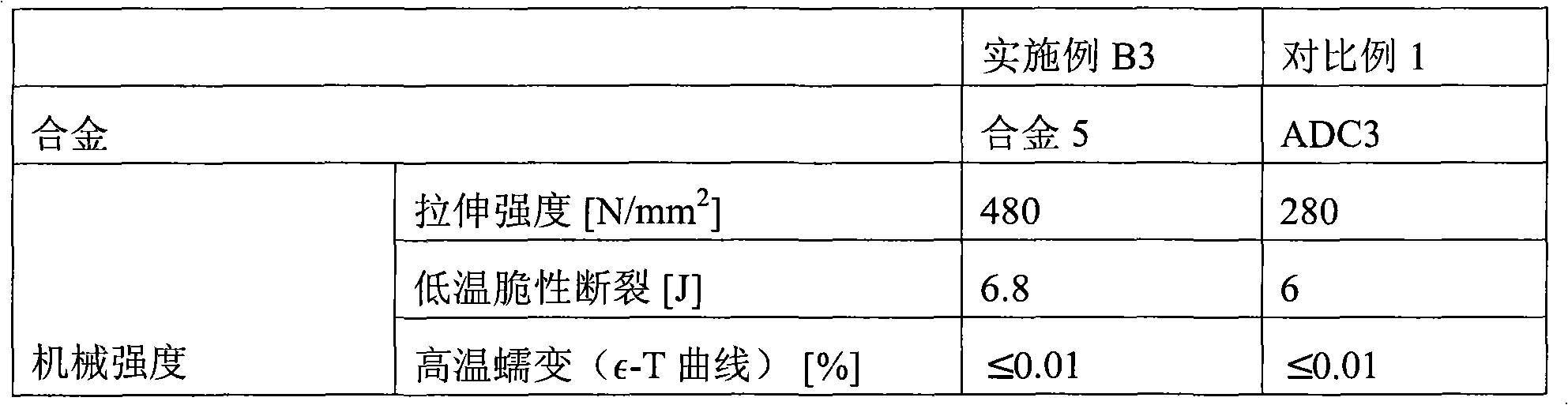

[0035] The present invention is illustrated below with reference to examples.

[0036] In the following examples, Examples A1-A4 and B1-B4 illustrate the precision alloy for die casting of the present invention, and Example A5 illustrates the method for producing the precision alloy for die casting of the present invention. Examples A6-A9 illustrate die cast parts using the precision alloy for die casting of the present invention.

[0037] It should be noted that the numerical range represented by "-" herein refers to a range in which the numerical values before and after "-" are respectively used as upper and lower limits and the upper and lower limits are included.

Embodiment Al

[0039] Alloy 1 comprising aluminum, zinc and silicon was prepared.

[0040] The main purpose of the present invention is to perform precision casting, specifically to minimize the draft angle and reduce the specific gravity of the alloy while maintaining the inherent advantages of zinc as a solid metal lubricant. More specifically, the precision alloy for die casting of the present invention is set to contain 40-45% by mass of aluminum and 30-57% by mass of zinc as main metals, and contains 2-8% by mass of silicon, arbitrary composition adjustment Metals and unavoidable impurities.

[0041] Silicon (Si) has an effect of improving castability (casting fluidity), and is useful for suppressing separation of aluminum and zinc so that they are uniformly dispersed among each other. Although the aluminum content in the present invention is set to be greater than that in conventional zinc alloys, the decrease in castability due to increased aluminum content can be suppressed by addin...

Embodiment A2

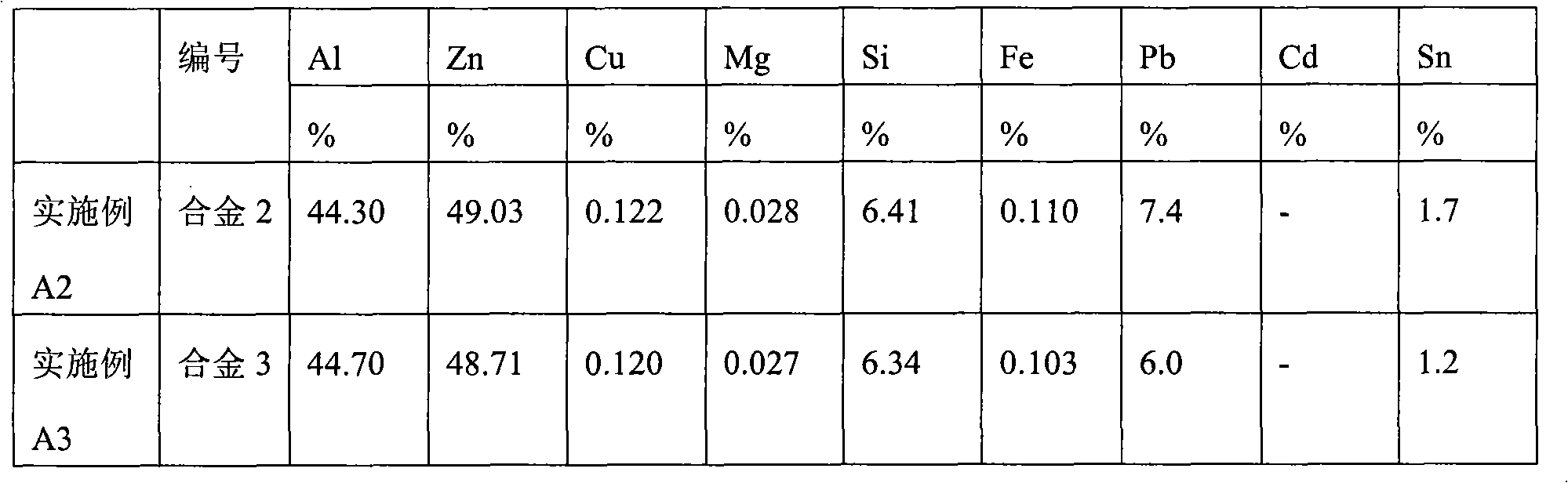

[0048] Alloy 2 comprising aluminum, zinc, silicon, copper and magnesium was prepared. The alloy compositions of this example are shown in Table 1.

[0049] The precision alloy of the present invention may also contain other composition adjusting elements, if necessary. As a component adjustment element, copper and / or magnesium can be contained, for example.

[0050] In the precision alloy of the present invention, copper (Cu) functions to improve machinability, and it is preferable to adjust copper to 0-0.5% by mass relative to the weight of zinc. In the precision alloy of the present invention, the copper content may preferably be 0.1-0.2% by mass, more preferably 0.1-0.17% by mass relative to the total weight of the alloy. If the copper content is too small, the above characteristics cannot be brought to a sufficient level, while if the copper content is too large, the fluidity will be deteriorated.

[0051] Magnesium (Mg) functions to prevent intergranular corrosion that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com