Conductive carbon fibre slice and solid polymer electrolytic fuel cell

A conductive carbon fiber, fuel cell technology, applied in solid electrolyte fuel cells, fuel cell parts, thin material processing, etc., can solve problems such as weakening gas diffusion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

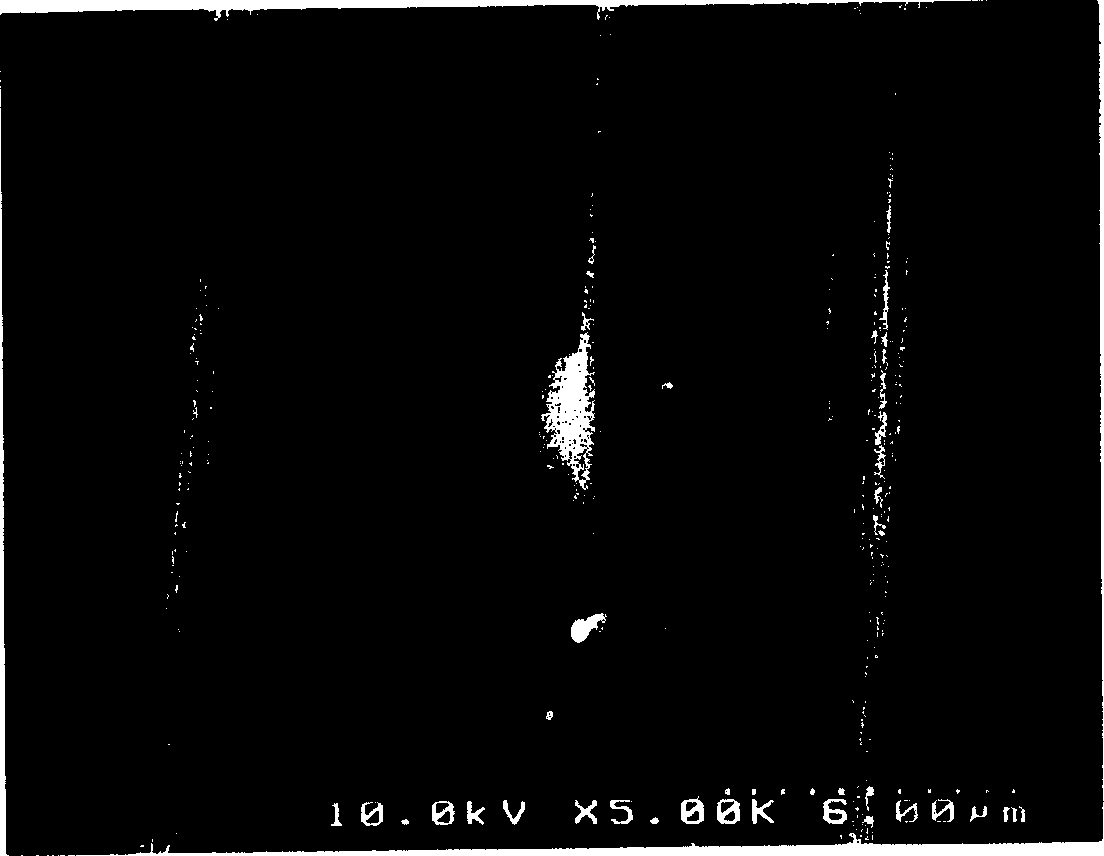

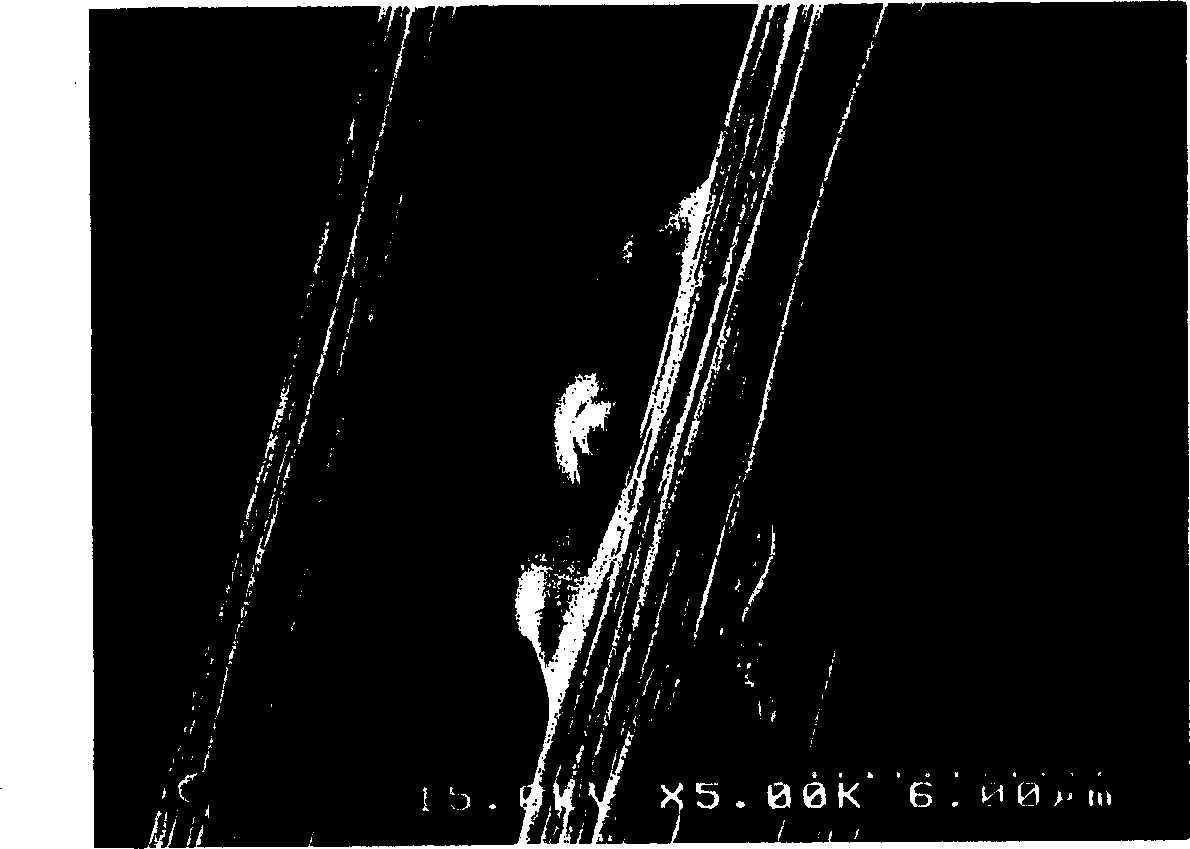

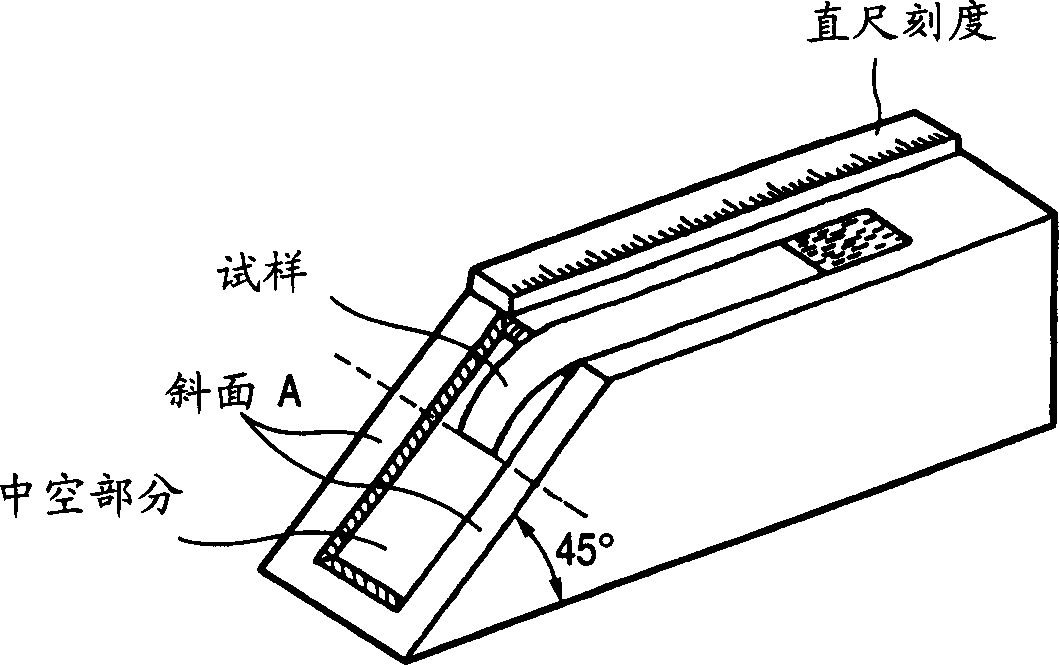

[0074] A double-ply (2 / 40 Nm) of single yarns, woven at warp and weft densities of 50 and 46 threads per inch, respectively, yields an oxidized plain weave woven fabric, the single yarns being gathered Long oxidized fibers (LOI value, 38) of 45-50 with a filament diameter of 8 microns and crimped polyacrylonitrile groups were obtained. The woven fabric was carbonized by heating to 900°C in a nitrogen stream, and then graphitized by heating to 2000°C in an argon atmosphere. The graphitized carbon fiber woven cloth has a warp density of 70 threads per inch (corresponding to 276 threads per 10 cm) and a weft density of 54 threads per inch (corresponding to 213 threads per 10 cm).

[0075] The obtained carbon fiber woven cloth was immersed in a phenolic resin ethanol solution (resole type) having a concentration of 3% by weight. The woven fabric was dried at 100°C, and then hot-pressed at 220°C to obtain a conductive carbon fiber woven fabric. Therefore, the amount of phenolic r...

Embodiment 2

[0077] A conductive carbon fiber woven cloth was obtained in the same manner as in Example 1, except that a phenolic resin solution (resole type) having a concentration of 1.5% by weight was used. The properties of the woven fabric are shown in Table 1.

Embodiment 3

[0079] A conductive carbon fiber woven cloth was obtained in the same manner as in Example 1, except that a phenolic resin solution (resole type) having a concentration of 6% by weight was used. The properties of the woven fabric are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com