Hoisting method of large mill housing under limited hoisting height

A rolling mill archway and hoisting method technology, which is applied in the direction of metal rolling frame, metal rolling mill stand, metal rolling, etc., can solve the problems that hoisting machinery cannot enter the site, and the archway is difficult to achieve at attention, so as to solve the installation problem, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

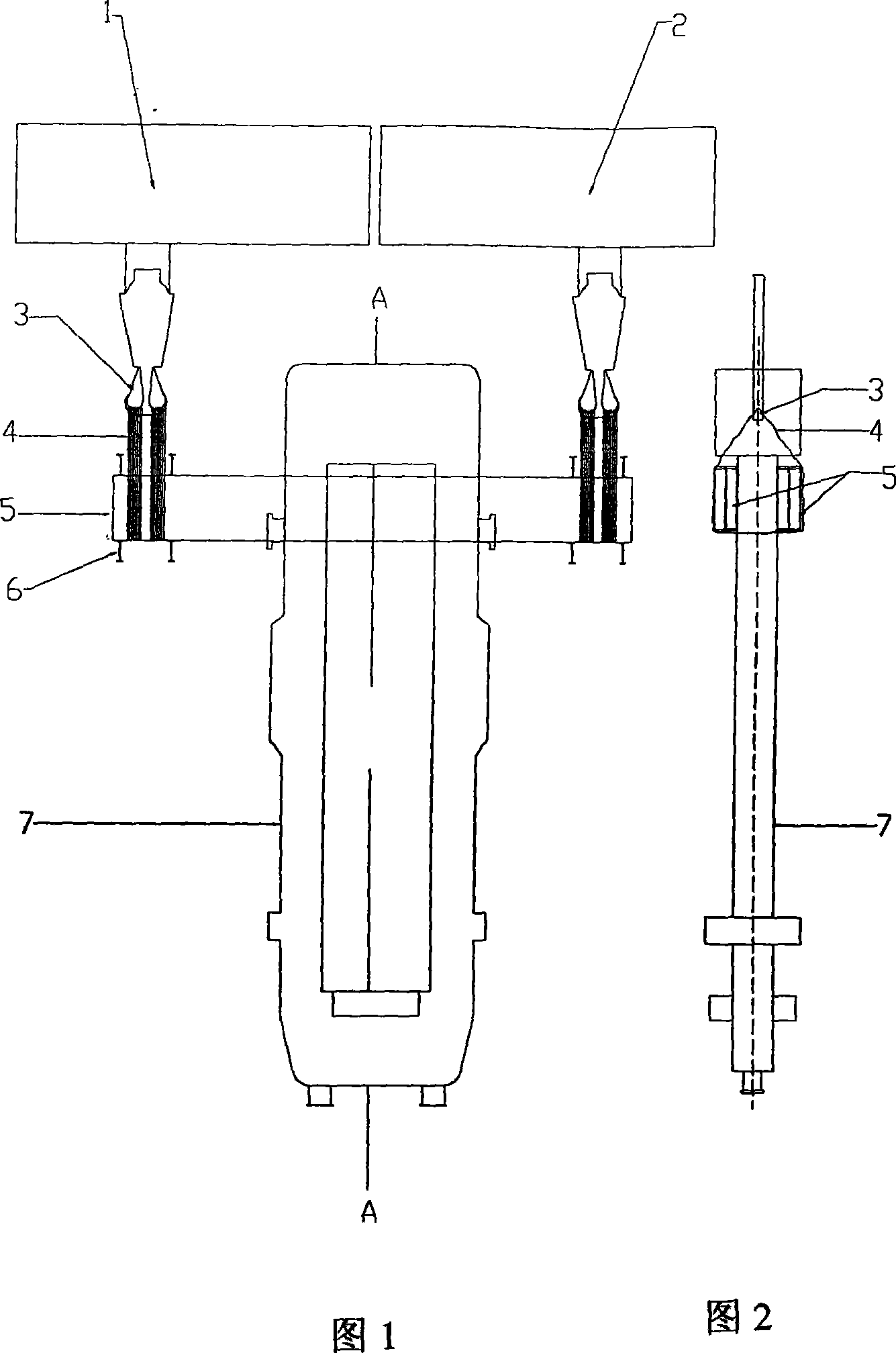

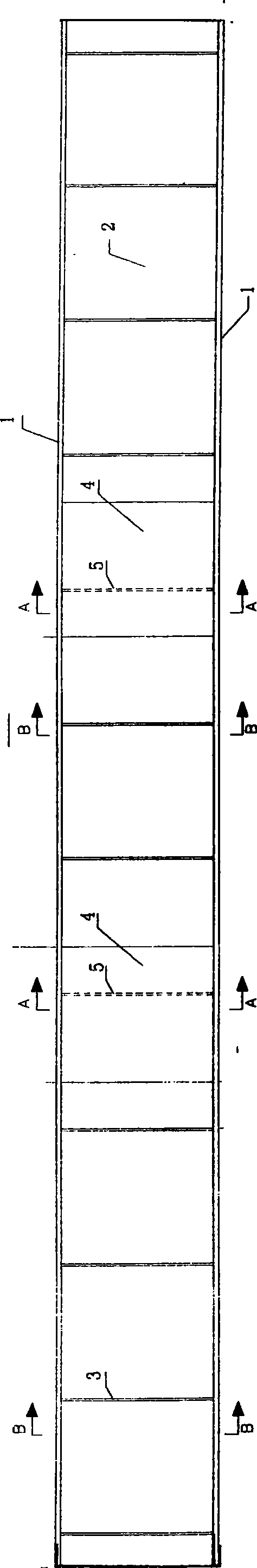

[0029] With reference to Fig. 1, 2, concrete steps of the present invention are as follows:

[0030] 1) Design and manufacture the lifting beam:

[0031] ①Calculate the design drawing of the lifting beam through detailed force analysis and design, and make two lifting beams 5;

[0032] ②The welding quality in the beam lifting process should be strictly controlled, and ultrasonic flaw detection should be carried out according to the requirements of the first-level weld seam, and the qualified ones should be transported to the construction site for use.

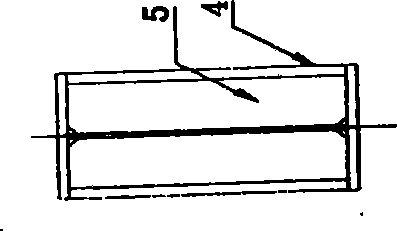

[0033] 2) Binding of archways and beams:

[0034] ① According to the force analysis, set the position of the lifting point, place the lifting beam on both sides of the stressed part of the rolling mill archway 2, select a qualified steel wire rope 4 of a certain specification for the binding operation, and carefully check the force of the steel wire rope, and use a clamp on the upper lifting point. Buckle and lock the wire ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com