Machining unit for a milling and drilling machine

A technology of mechanical processing, drilling and milling machines, which is applied in the direction of milling machines, milling machine equipment, metal processing equipment, etc., and can solve problems such as chip damage and collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

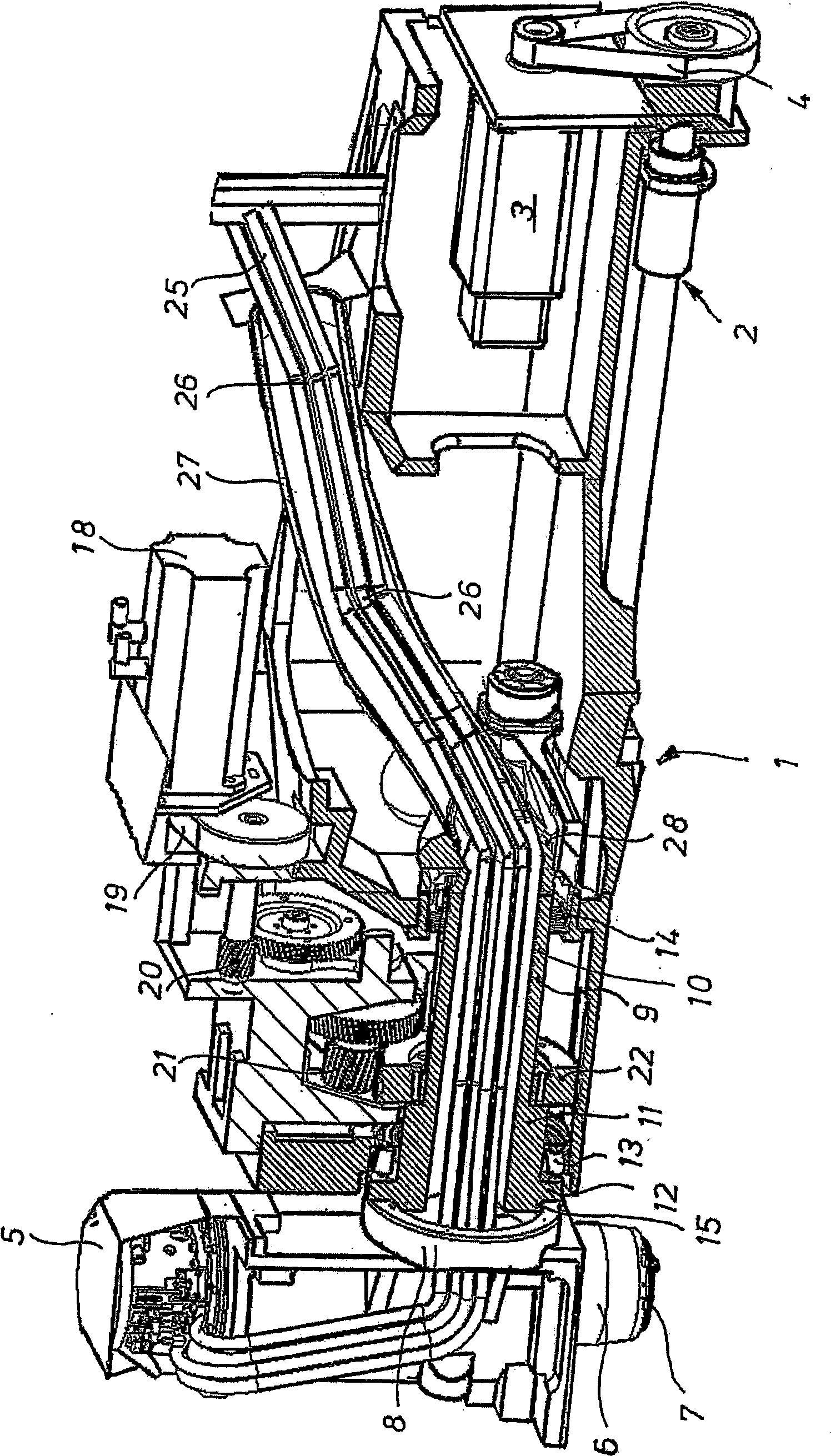

[0009] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings, in which a machining unit for a drilling and milling machine is schematically illustrated in longitudinal section.

[0010] The illustrated machining unit comprises a spindle housing 1 which is arranged on the assembly of the drilling and milling machine via guide rails (not shown) and is guided and slidable in the longitudinal direction. The spindle drive 2 is used for the longitudinal movement of the machining unit, which in this case contains a so-called recirculating ball screw driven by an electric motor 3 via a belt drive 4 . At the left end of the spindle housing 1 in the figure, a vertical milling head 5 is mounted and rotatable about a horizontal axis into selectable operating positions. A work spindle 6 is supported in this milling head 5 , which is driven by an internal motor and has a tool-holding clamp 7 at its lower end.

[0011] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com