Equipment and method for producing polystyrene extruded plastic foam insulated pipes

A technology for polystyrene and production equipment, applied in the field of polystyrene plastic extrusion foam production, can solve the problems of low production efficiency, discontinuous extrusion of extruded foam insulation pipes, etc., so as to improve production efficiency and reduce production Cost, the effect of good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

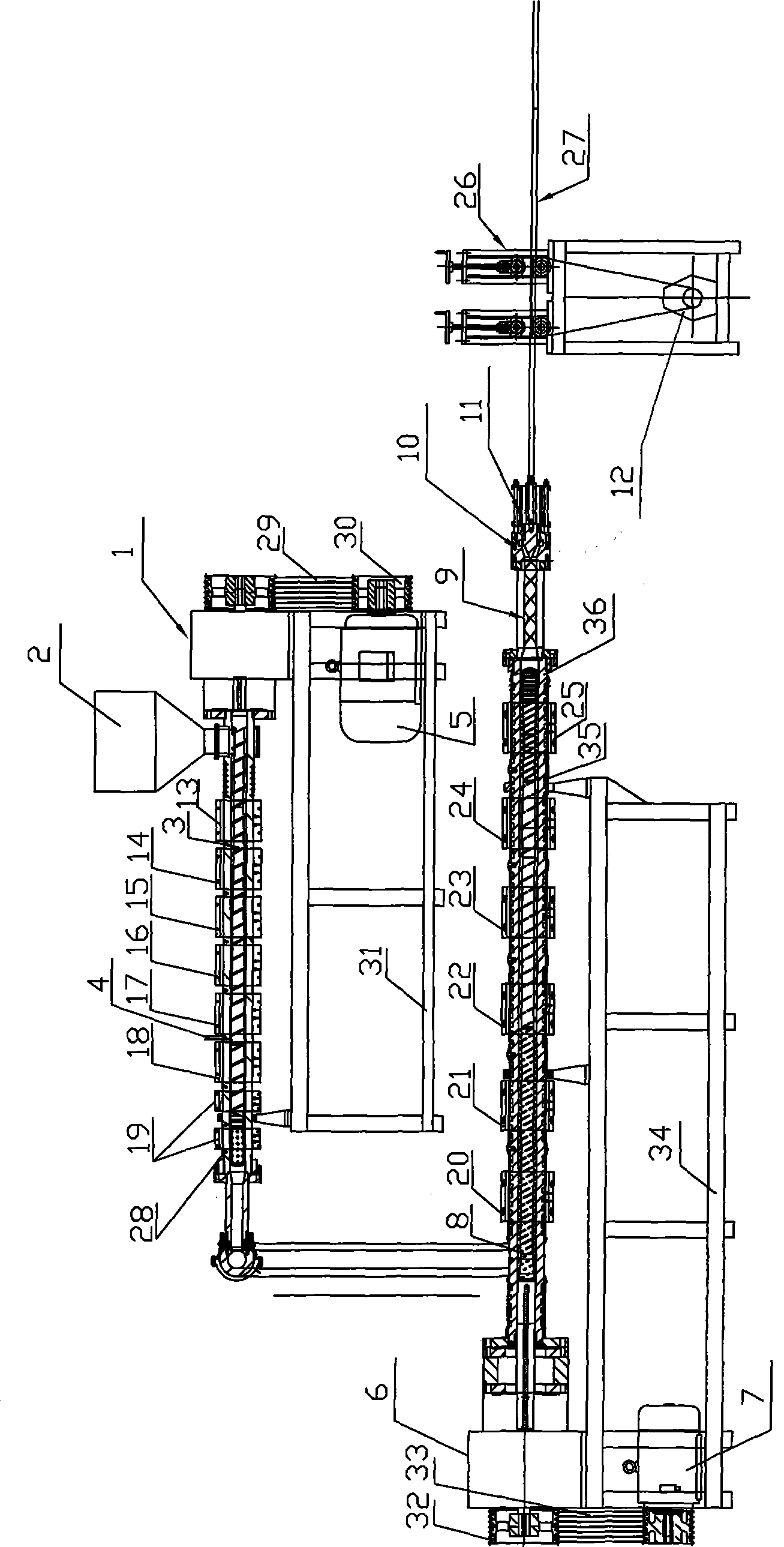

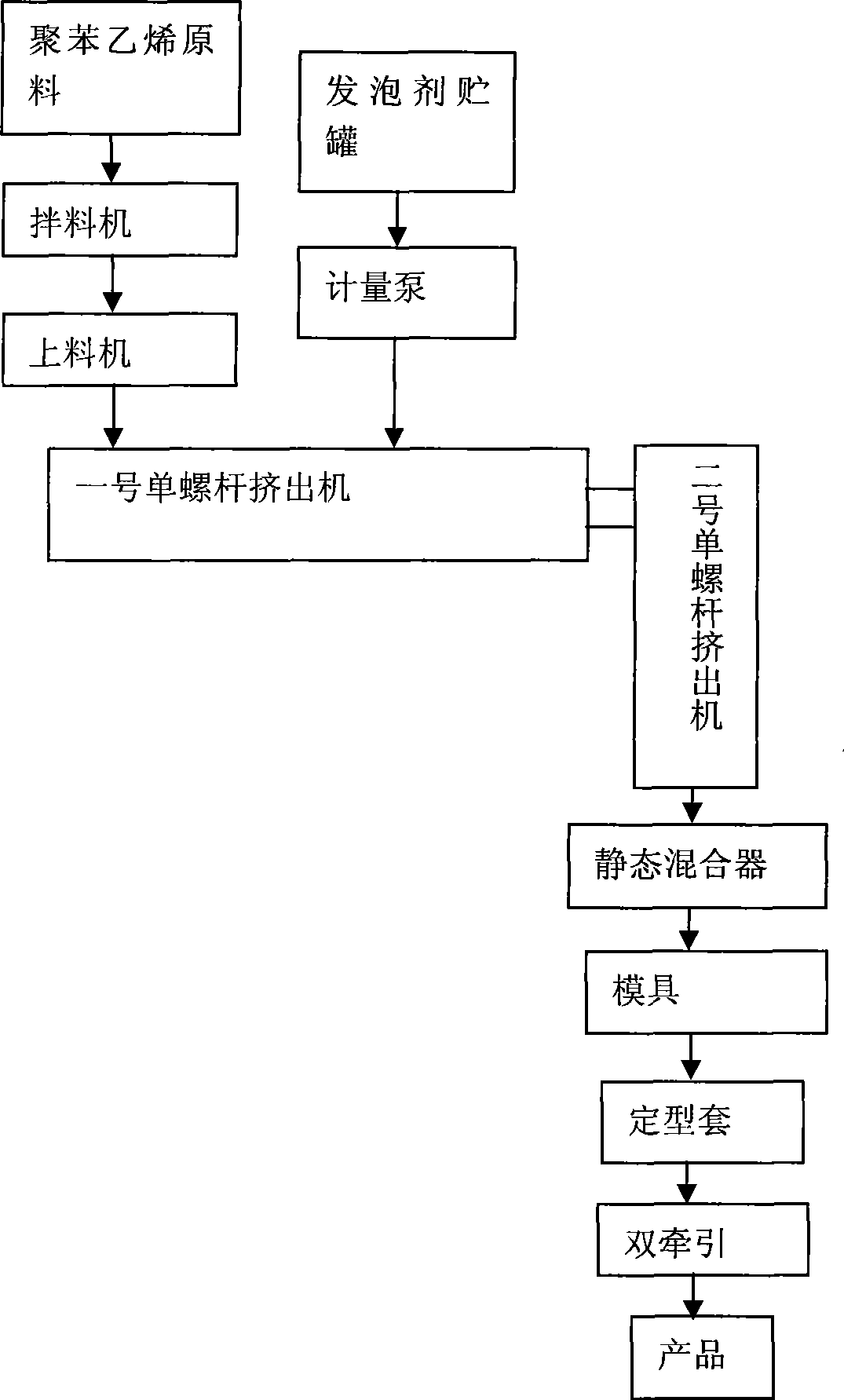

[0018] Refer to attached figure 1 , 2 , The polystyrene extruded foam insulation pipe production equipment consists of a feeding part, a foaming agent injection part, a No. 1 single-screw extruder 1, a No. 2 single-screw extruder 6 and a double-roller tractor 26. The feeding part is composed of a mixer and a feeding machine. The mixing machine is a commercially available blade type mixer, and the feeding machine is a commercially available screw feeder. The polystyrene raw material passes through the mixing machine and the feeding part The feeder enters the hopper 2 of the No. 1 single-screw extruder 1; the foaming agent injection part includes a foaming agent storage tank and a metering pump. The foaming agent is a carbon dioxide mixed foaming agent or Freon foaming agent. The point is located at the middle end of No. 1 single-screw extruder 1, and the foaming agent is injected through a metering pump, and the metering pump adopts a commercially available metering pump; No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com