Crystal growth furnace body structure with emergency decompression arrangement

A technology of crystal growth furnace and pressure relief, applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of difficult discharge of pressure, explosion of furnace body, and insufficient circumferential extension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

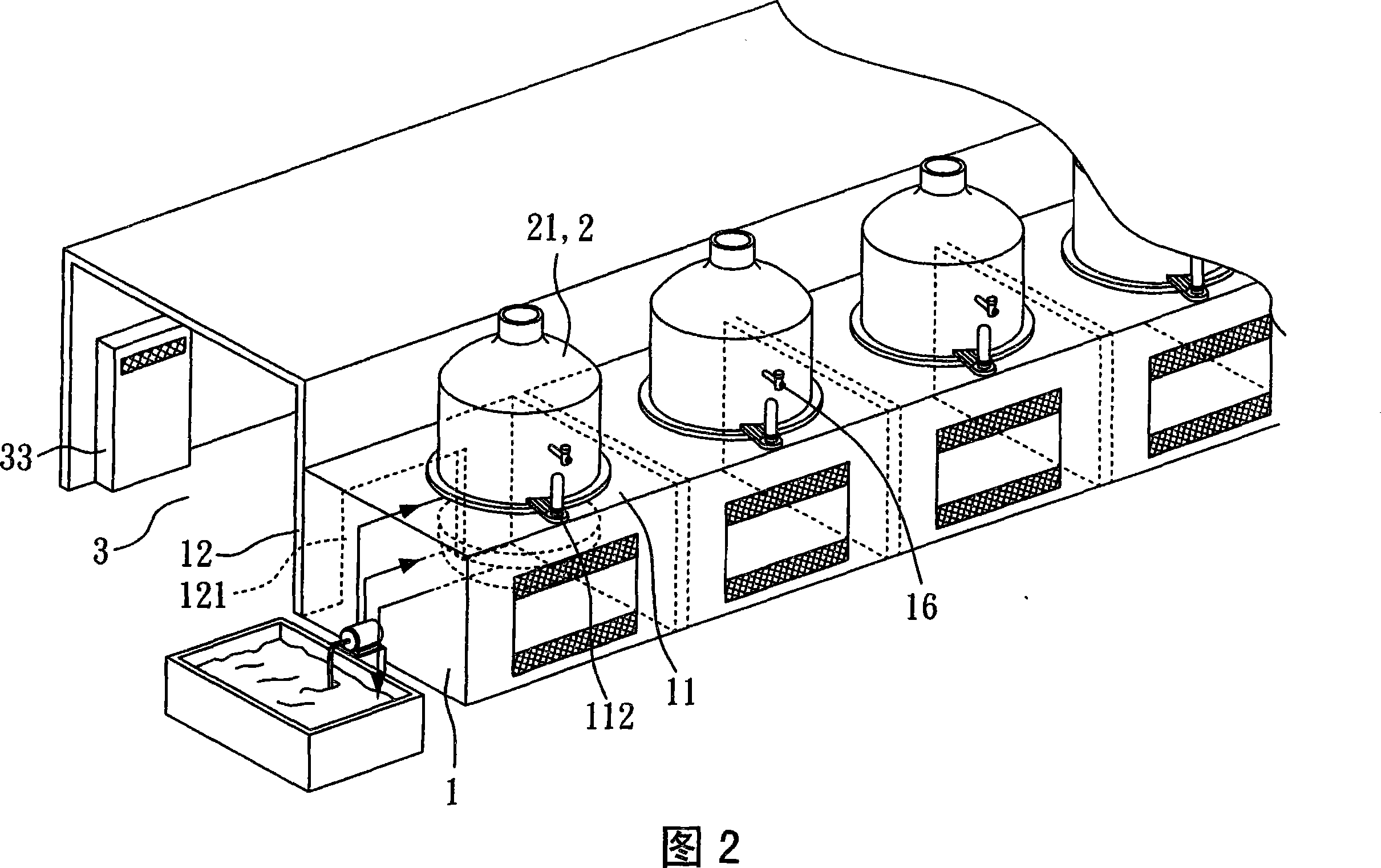

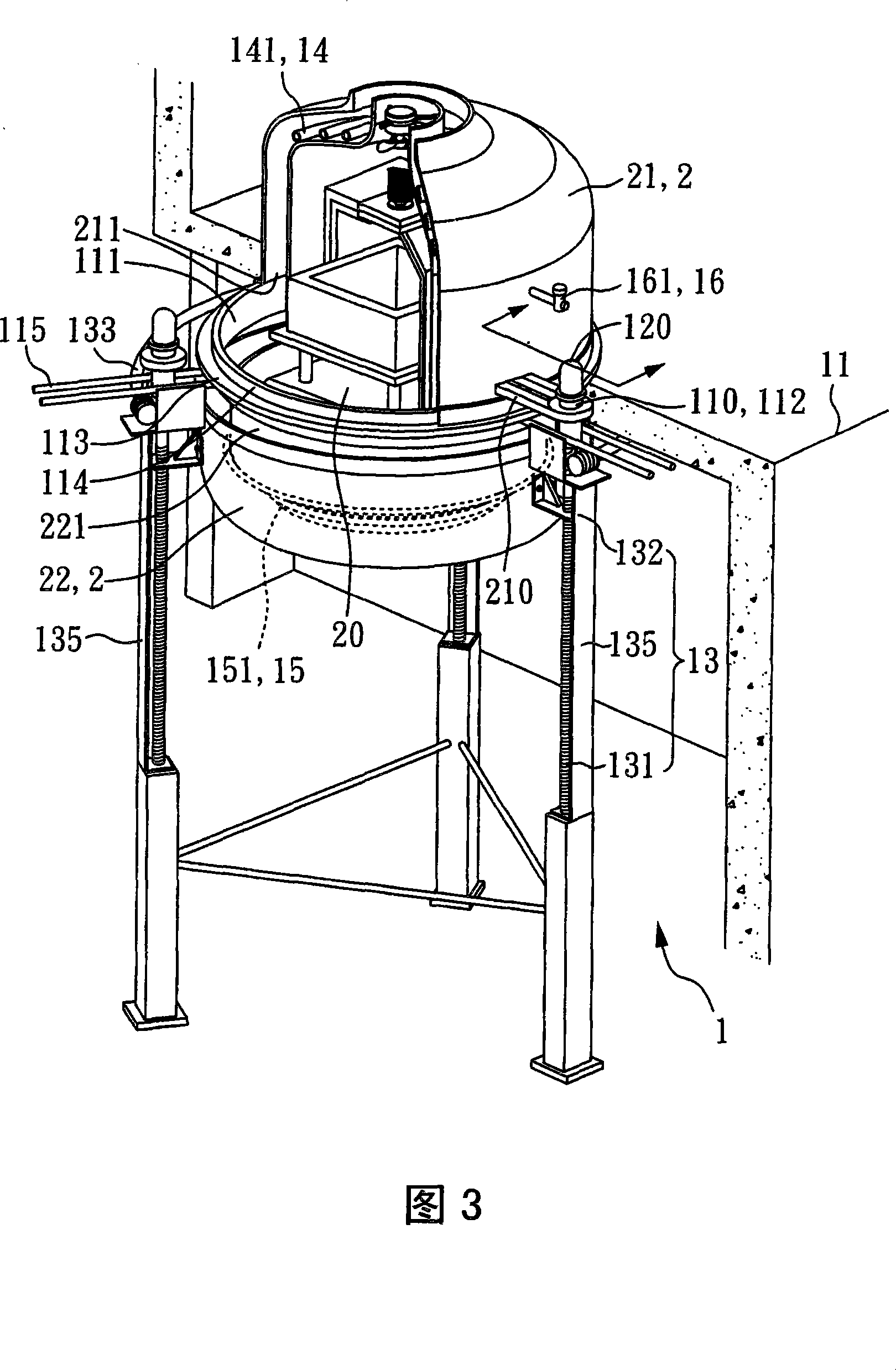

[0055] Please refer to FIG. 2 and FIG. 3 together. FIG. 2 is a system structure diagram of a preferred embodiment of the present invention, and FIG. 3 is a perspective view of a preferred embodiment of the present invention. As shown in the figure, this embodiment is a crystal growth furnace structure with an emergency pressure relief configuration, including an isolation chamber 1 and a furnace upper chamber 21 .

[0056] As shown in Figure 2 and Figure 3, the isolation chamber 1 includes a top plate 11, the top plate 11 includes a through opening 111, and at least one first guide 112, at least one first guide 112 protrudes above the top plate 11 and Adjacent to the opening 111 , the isolation chamber 1 is provided with a furnace bottom cover 22 , and the furnace bottom cover 22 is provided with an upper opening 221 . The upper opening 221 is upwardly corresponding to the opening 111 of the top plate 11 .

[0057] Please refer to FIG. 4 and FIG. 3 at the same time. FIG. 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com