Implanted pottery-stone connector for building decorative plates, and dry-hanging installation technique thereof

A technology of building decoration and installation method, applied in building structure, construction, covering/lining, etc., can solve the problems of noise disturbance, inconvenient construction, damage to board strength, etc., to achieve a quiet and safe working environment, reduce transportation costs and cost, the effect of ensuring the quality of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

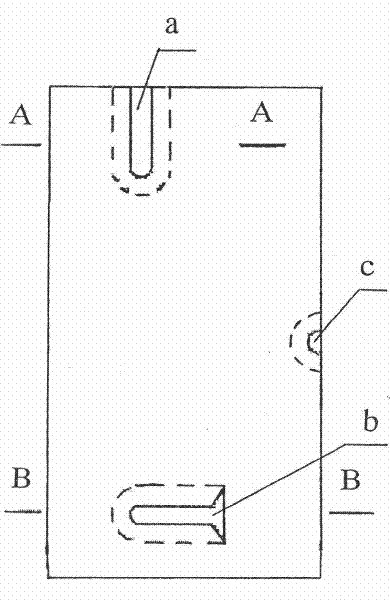

[0048] The present invention will be further described below in conjunction with accompanying drawing:

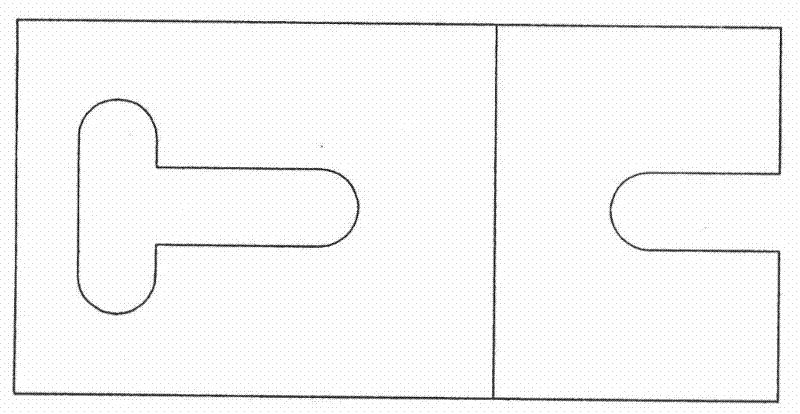

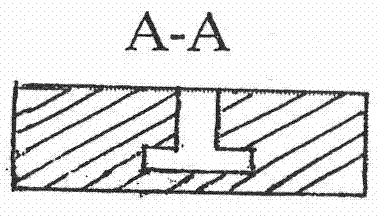

[0049] The pottery-stone connector used in the present invention is a special T-bolt, and the T-bolt is a pottery-stone connector. The T-shaped bolt has a flat plate on its end face, and the flat plate is oval, circular, square, triangular or other geometric shapes, and the connecting piece used in the present invention also includes an L-shaped connecting piece.

[0050] The dry-hanging method of the present invention is to cut the decorative materials into finished materials ready for dry-hanging according to the design requirements, and then plant anchor bolts in the factory or on the construction site. Put the T-bolt horizontally into the T-shaped slot after the drill bit opens the T-shaped slot.

[0051] The plate groove is T-shaped groove or L-shaped groove.

[0052] According to the construction design requirements, the board is cut into finished materials ready fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com