Three-cylinder concentric shaft kiln

A shaft kiln and outer cylinder technology, applied in furnaces, lime production, vertical furnaces, etc., can solve the problems of inability to simultaneously calcine large and small particles of limestone, large waste of limestone raw materials, and inability to be calcined in the kiln, so as to ensure calcination. The effect of quality, energy saving and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

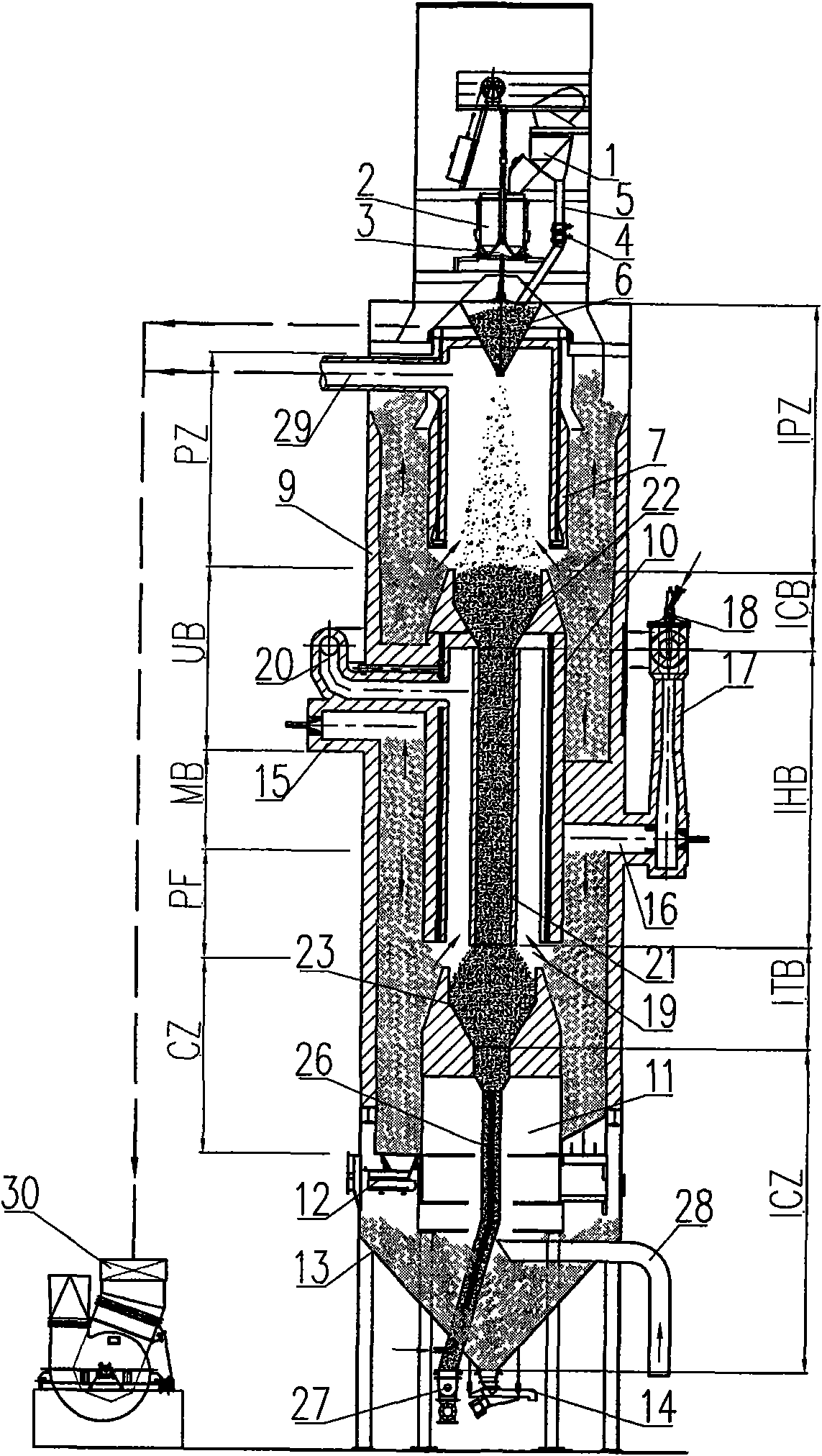

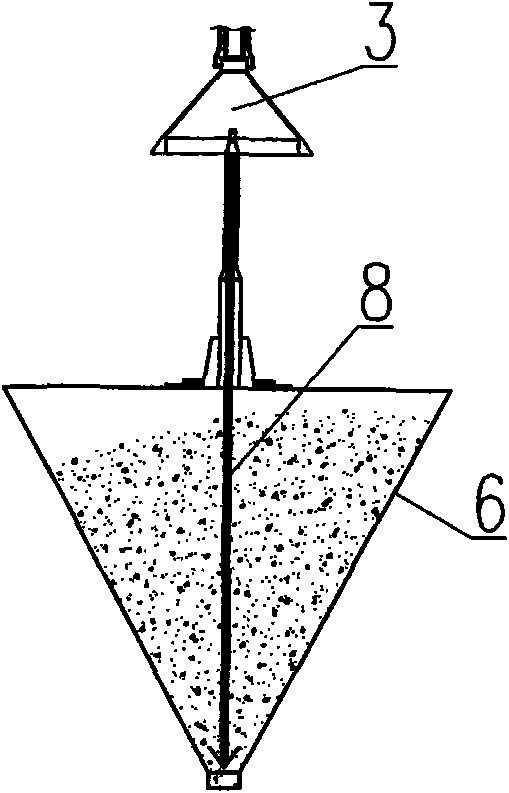

[0020] The three-tube concentric vertical kiln of this embodiment is as Figure 1 to Figure 3 As shown, the exhaust port of the smoke exhaust fan 30 leads to the kiln roof, and the smoke is exhausted from the kiln to form a negative pressure in the kiln. The top of the outer cylinder 9 is equipped with a distributing device including a bar sieve 1, a rotary distributor 2, a material cup 3, a throttling funnel 6, etc., and the middle part has two layers of combustion chambers 15 and 16. The bottom is equipped with an ash discharge device consisting of a vibrating ash discharge machine 14 located at the bottom of the kiln bottom silo 13 and a discharge port controlled by a star discharge valve 27 .

[0021] The outer cylinder 9 is concentrically provided with a middle cylinder consisting of the upper section 7 of the middle cylinder, the middle section 10 of the middle cylinder, and the lower section 11 of the middle cylinder. The outer cylinder 9 and each section of the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com