Temperature flow-type steam quality measurement device and measurement method

A technology of steam and dryness, which is applied in the direction of material moisture content, special data processing applications, instruments, etc., and can solve problems such as poor measurement stability and inability to obtain steam dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

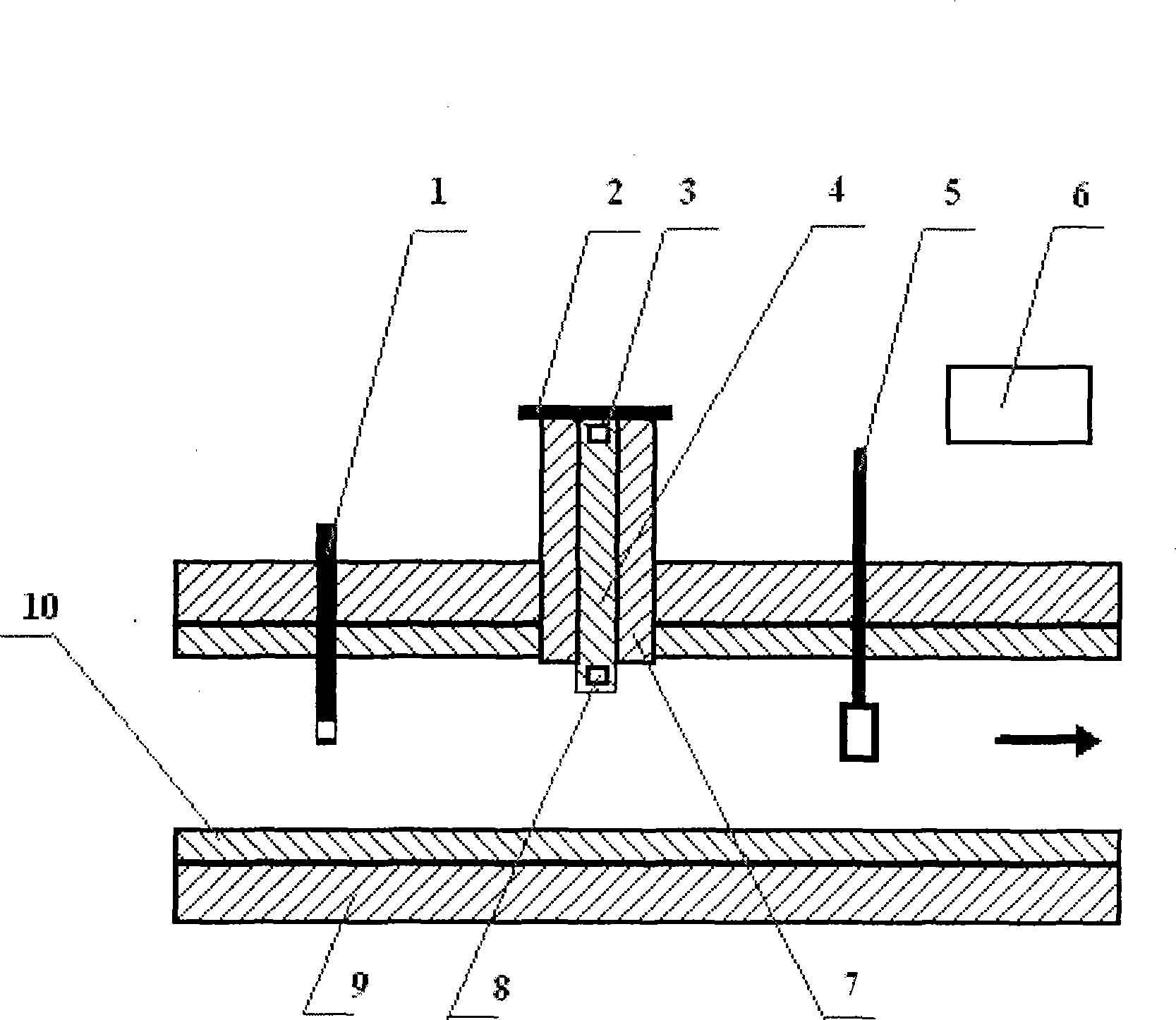

[0027] This embodiment is the application of the warm-flow steam dryness measurement method to measure the wet steam dryness in the steam pipeline.

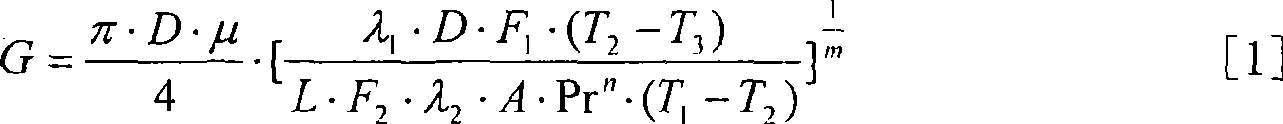

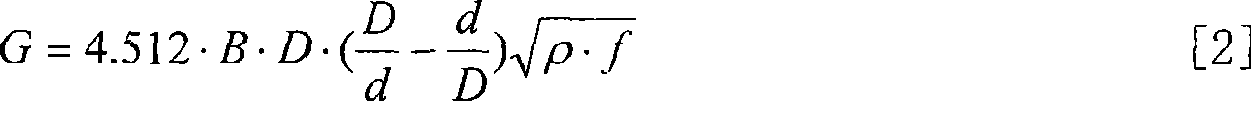

[0028] This embodiment includes steam temperature sensor 1, heat sink 2, heat transfer rod cold end temperature sensor 3, heat transfer rod 4, target flow meter 5, steam dryness processor 6, heat insulation sleeve 7, heat transfer rod thermal Terminal temperature sensor 8, steam pipeline insulation layer 9 and steam pipeline 10. Among them: the heat transfer rod 4 is a copper metal rod with a diameter of 5 mm and a length of 50 mm, and is wrapped by an expanded perlite heat insulation sleeve 7 with a length of 48 mm and a thickness of 6 mm. The hot end of the heat transfer rod 4 is directly in contact with the steam in the steam pipe , the cold end of the heat transfer rod 4 is fixed to the copper metal circular heat sink 2 with a diameter of 50 mm and connected to the ambient air. At the hot end of the heat transfer rod 4, a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com