Explosion-proof automatic-separation type lightning arrester

An automatic separation and arrester technology, applied in the field of arresters, can solve the problems of crushing and explosion of the arrester, poor heat transfer effect, and inability to reliably separate, and achieve the effect of preventing the explosion of the arrester.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

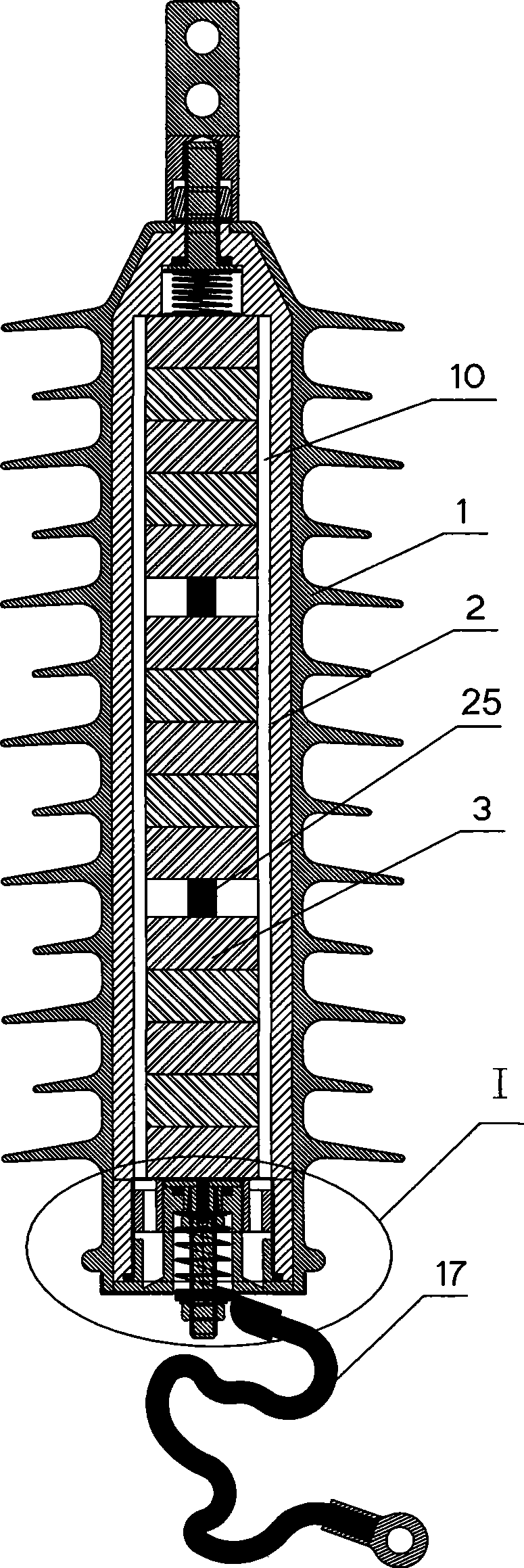

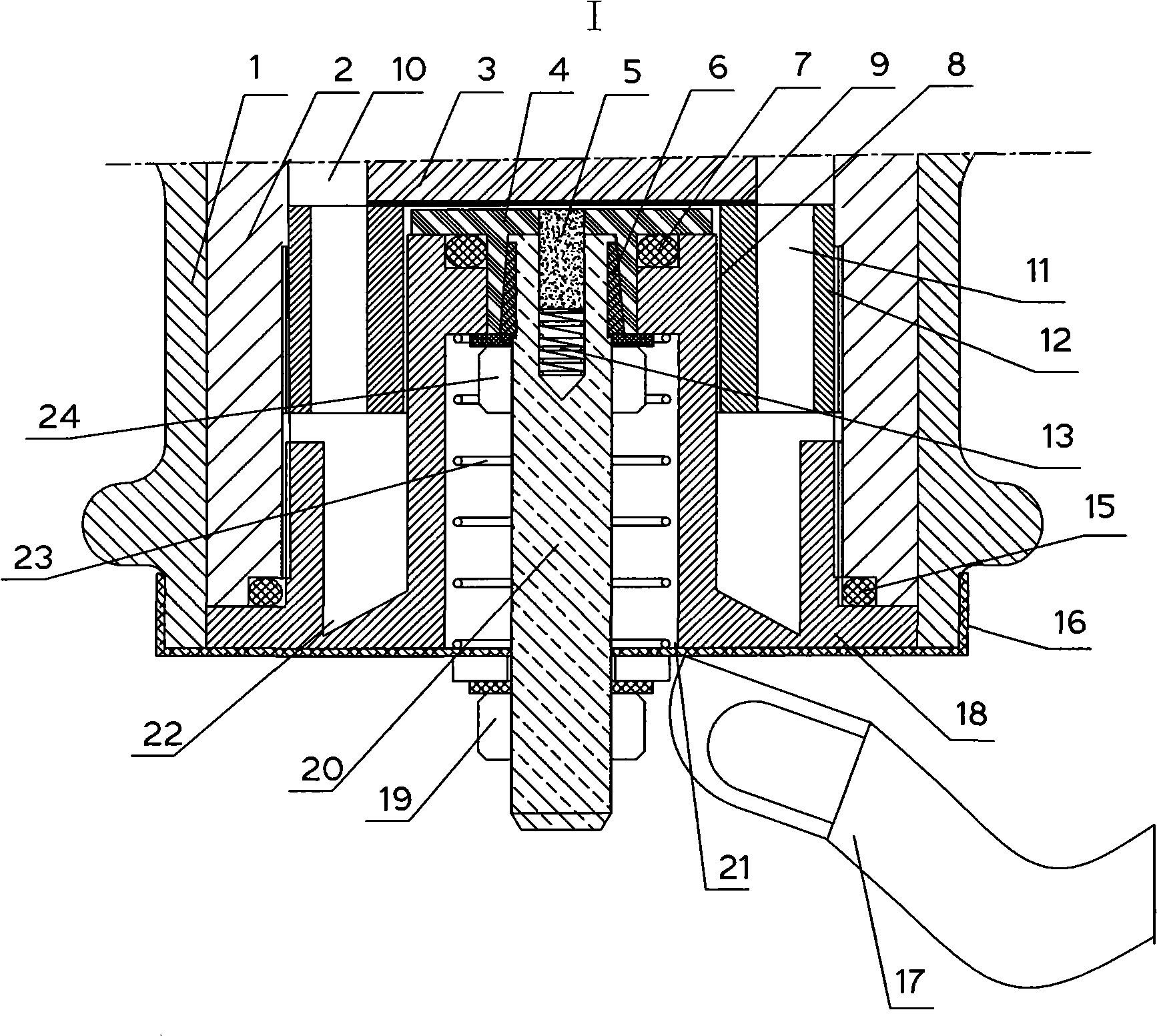

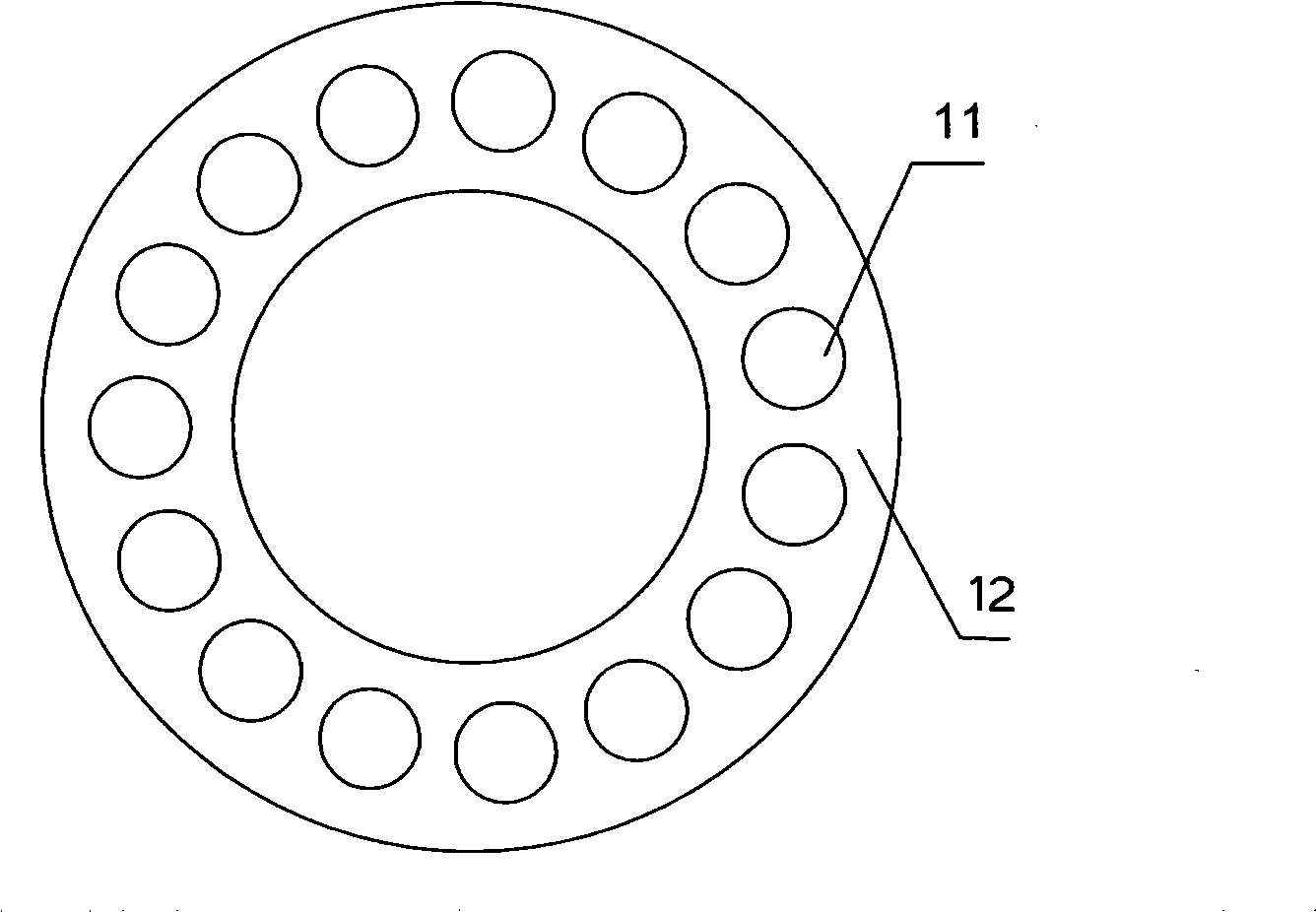

[0019] Such as figure 1 , 2 , 3, an explosion-proof automatic detachment type arrester, including high temperature and high voltage resistant insulation cylinder 2, the insulation cylinder 2 is provided with a silicone rubber jacket 1 made of silicon rubber, and the insulation cylinder 2 is provided with a multi-layer oxidation Zinc valve sheet 3, between the multilayer zinc oxide valve sheet 3 and the inner wall circumference of the insulating cylinder 2 is provided with a heat dissipation ventilator 10, which improves the heat dissipation effect of the zinc oxide valve sheet 3 and improves the service life of the arrester, and at the same time the heat dissipation ventilator 10 is also When the lightning arrester is impacted by strong lightning, the high temperature and high pressure gas generated by the internal flashover of the zinc oxide valve plate 3 is transmitted to the channel of the explosion-proof detachment cover 18 to ensure the reliability of the explosion-proof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com