Insert part, gas lens with the insert part and welding torch with the gas lens

A technology of inserting components, gas, applied in the direction of manufacturing tools, electrode characteristics, welding equipment, etc., to achieve the effect of operation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

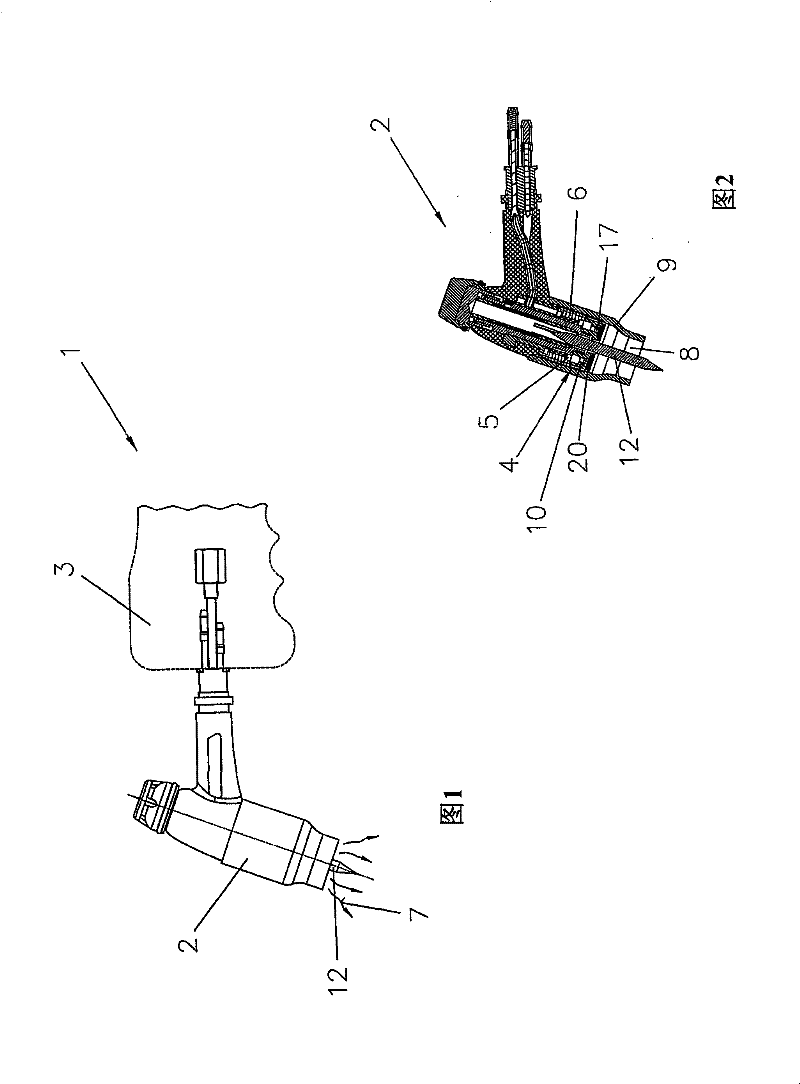

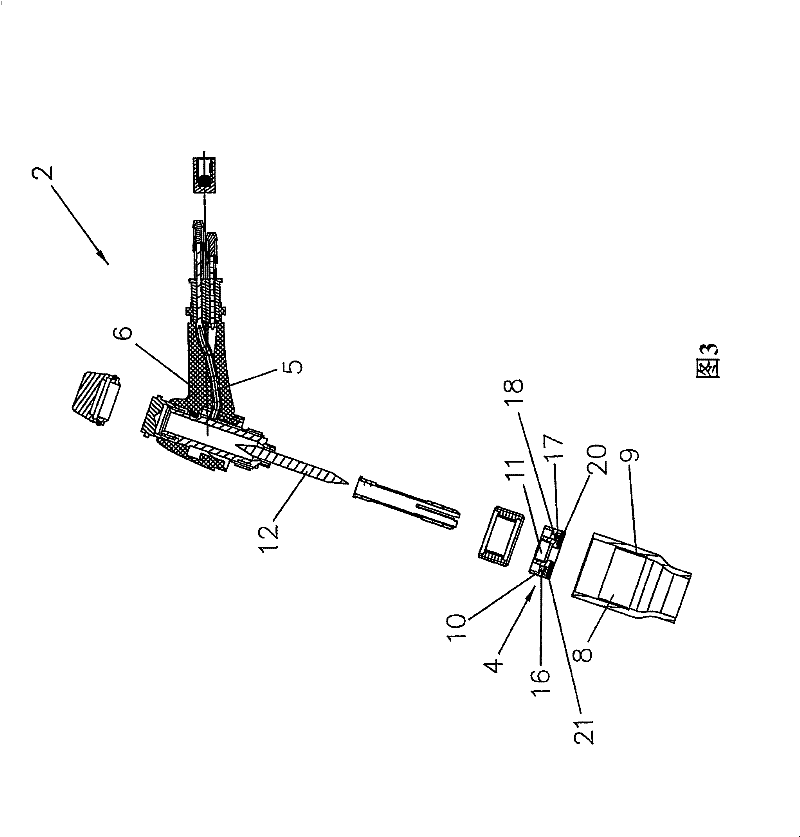

[0028] Figure 1 to Figure 10 A WIG / TIG torch 1 is shown. The welding torch 1 includes a welding torch body 2 and a welding torch handle 3 . Here, the structures of the various components of the welding torch 1 correspond to those in the prior art, so these components and their functions will not be described in detail.

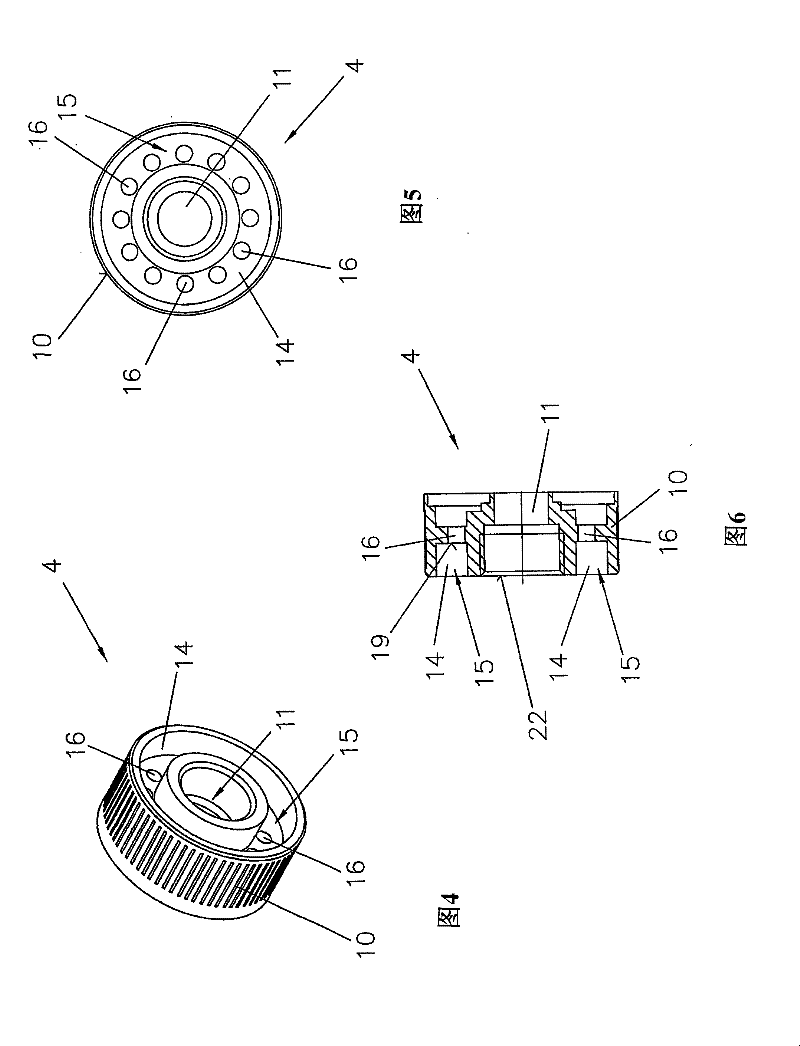

[0029] The invention is a detailed solution for the gas lens 4 provided in the torch body 2 for distributing the gas 7 fed through the gas supply channel 5 in the base 6 . The gas 7 fed through the base 6 flows from the base 6 into the gas lens 4 and will then be dispersed through the cross-section of the gas lens 4 . This allows an optimum distribution of the gas in the gas nozzle 9 as the gas 7 flows out of the gas lens 4 and into the interior 8 of the gas nozzle 9 . It is critical here that the size of the gas lens 4 be as small as possible, as this reduces the overall size of the welding torch 1 and greatly improves the handling of the welding torch 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com