Process for disposal of mercaptans

A technology for mercaptans and sulfides, applied in separation methods, gas treatment, sulfur preparation/purification, etc., can solve problems such as the limitation of the amount of mercaptans and disulfides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

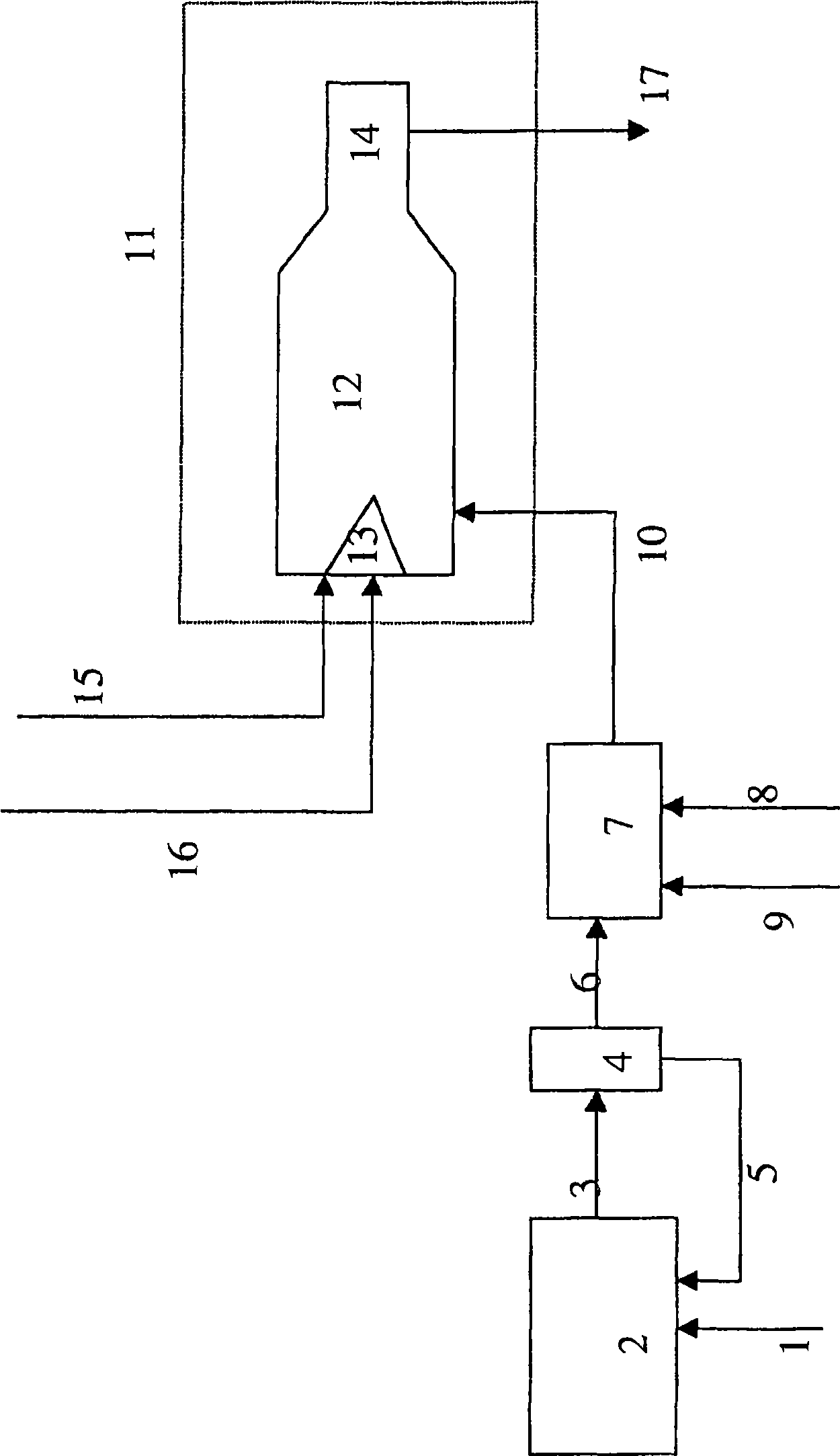

[0056] The present invention will be described below by way of embodiments with reference to the accompanying drawings. In the Figure, a mercaptan-containing feed gas stream is directed via line 1 to a sulfide production zone 2 . In the sulfide production zone, mercaptans are converted to sulfide compounds. The resulting liquid stream containing sulfide compounds is directed via line 3 to a liquid / liquid separator 4 where it is separated into a first liquid phase rich in liquid sulfur and a second liquid phase rich in sulfide compounds. The sulfur-rich first liquid phase is directed via line 5 to the sulfide production zone. The second liquid phase rich in sulphide compounds is directed via line 6 to the sulfur dioxide generating zone of the sulphide-comprising burner 7 . Oxygen-containing gas is supplied via line 8 to the sulphide burner. Nitrogen is optionally supplied as injection medium via line 9 to the sulfide burner. In a sulfide burner, sulfide compounds burn to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com