Biodegradable resin composition

A biodegradable, resin composition technology, applied in the field of biodegradable resin compositions, can solve the problems of decreased transparency, plasticizer exudation, insufficient crystallization speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-9

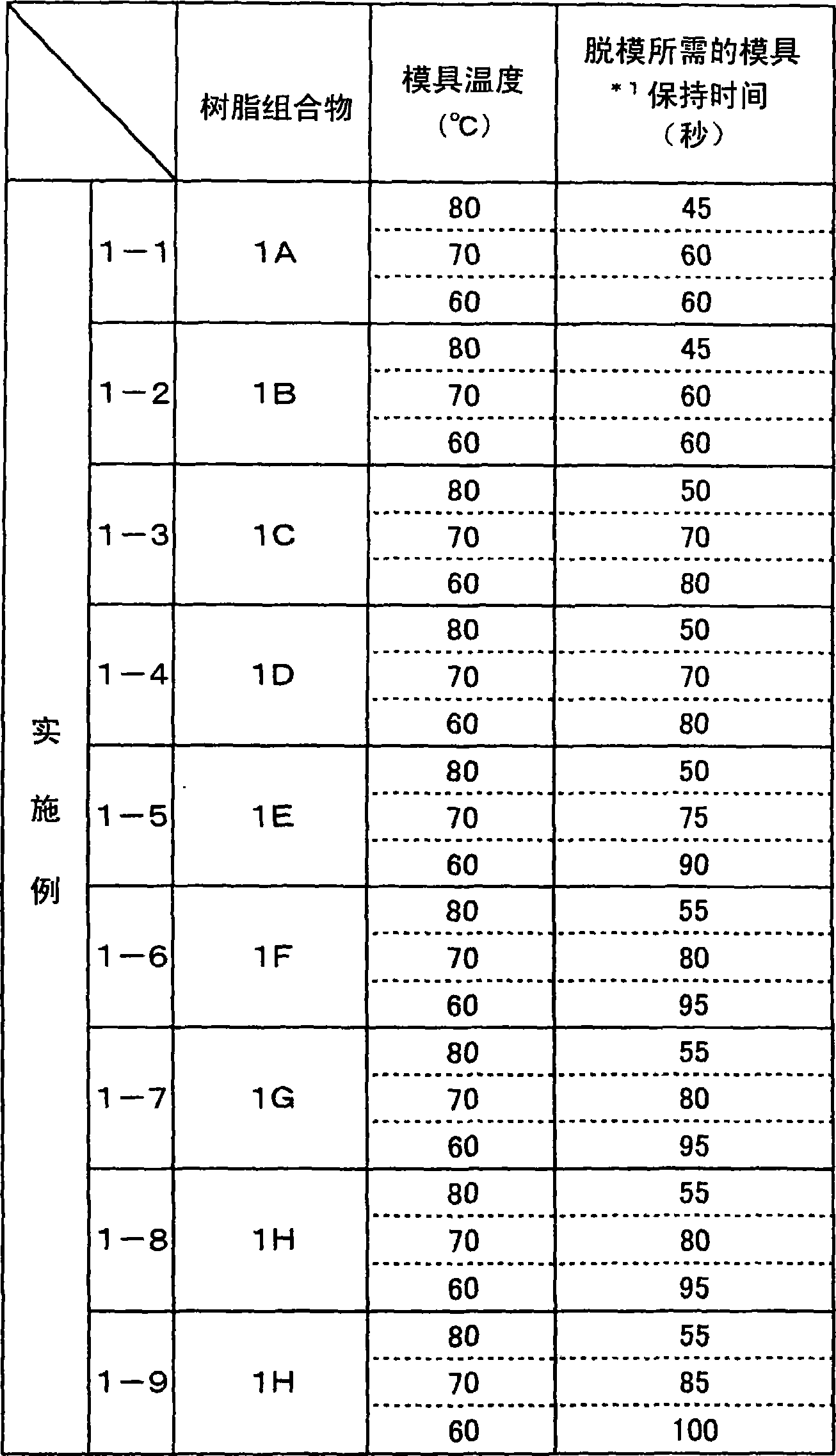

[0067] Examples 1-1 to 1-9, Comparative Examples 1-1 to 1-9

[0068] As a biodegradable resin composition, the products of the present invention (1A to 1I) shown in Table 1-1 and the comparative products (1a to 1i) shown in Table 1-2 were mixed with a kneader (DS3 manufactured by Moriyama Seisakusho Co., Ltd.). -20MWB-E) Melt and knead at 180°C for 10 minutes, then immediately stretch it to a thickness of about 5mm with an 8-inch roll (manufactured by Japan Roll Manufacturing Co., Ltd.) at 80°C, and cut it into length×width=8cm×8cm After the size was determined, it was pulverized with a pulverizer (S-20 manufactured by DAIKO Seiki Co., Ltd.) at a temperature below 40° C. to obtain a pulverized product of a biodegradable resin composition.

[0069] The obtained pulverized product was dried at 70° C. under reduced pressure for 1 day to reduce the water content to 500 ppm or less.

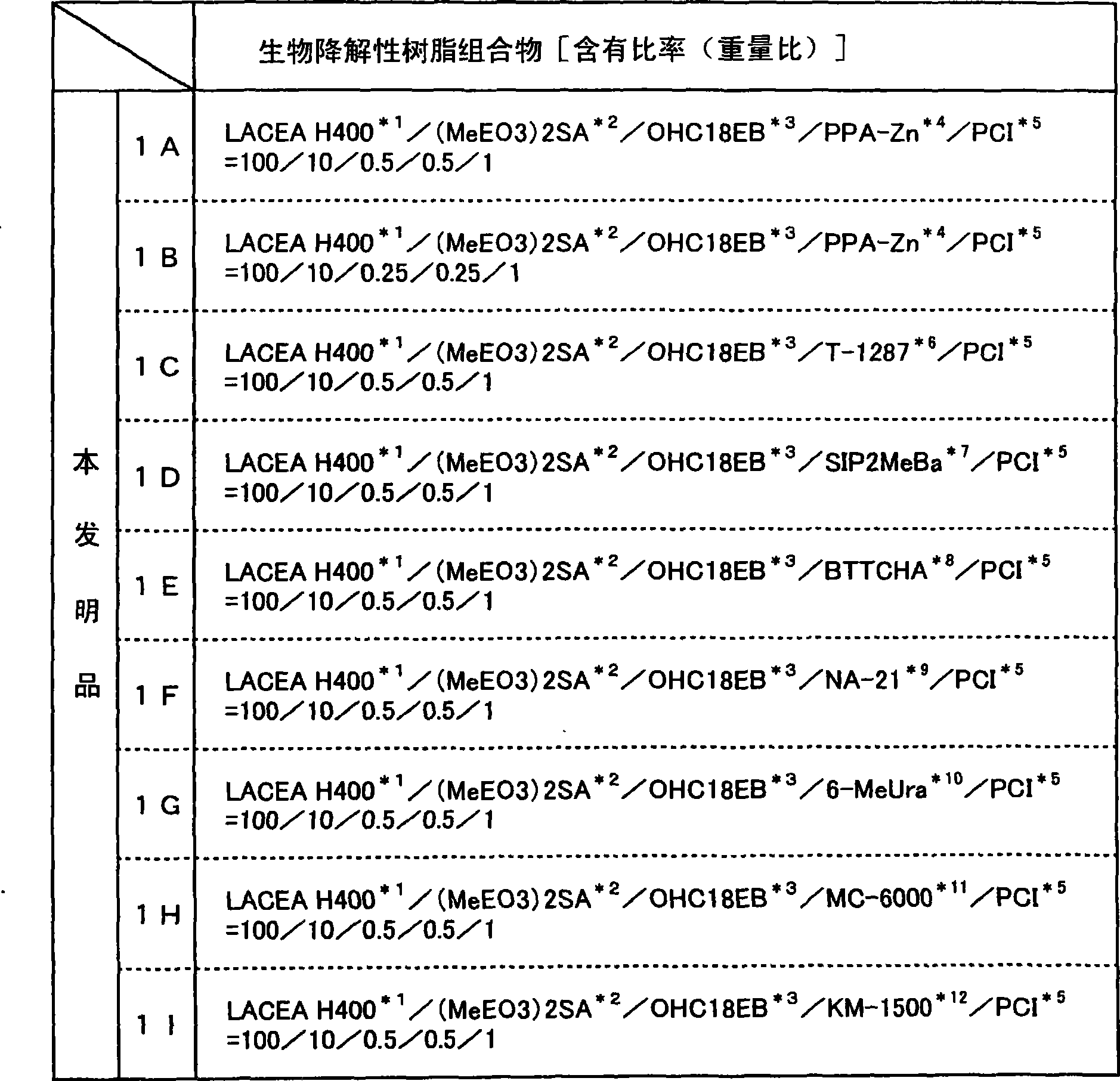

[0070] Table 1-1

[0071]

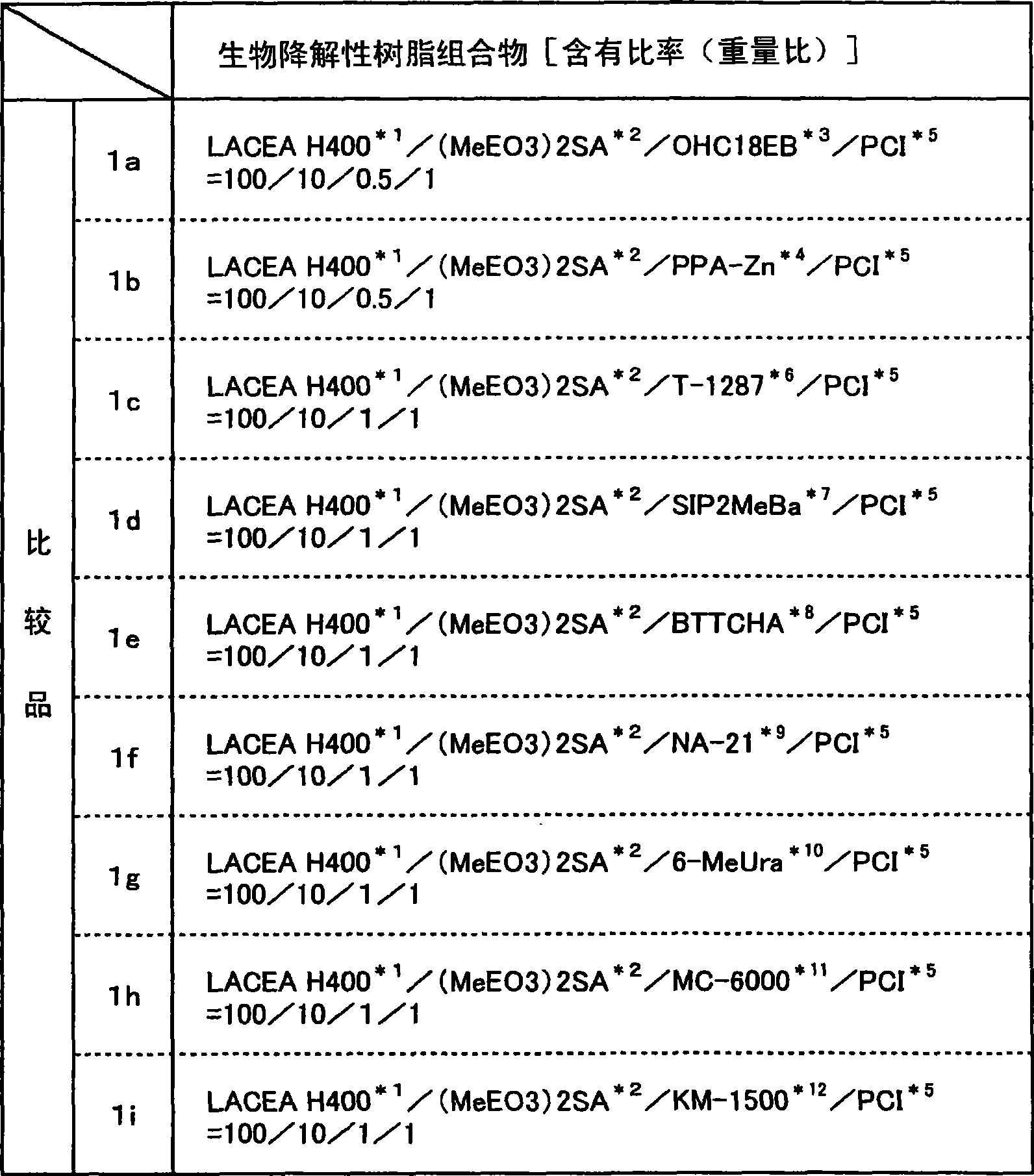

[0072] Table 1-2

[0073]

[0074] * 1: Polylactic acid resi...

Embodiment 1-10~1-11

[0098] Embodiment 1-10~1-11, comparative example 1-10~1-11

[0099] As the biodegradable resin composition, the products of the present invention (1A to 1B) shown in the above Table 1-1 and the comparative products (1a to 1b) shown in the above Table 1-2 were used in the same manner as in Example 1-1. A pulverized product of the biodegradable resin composition was obtained.

[0100] The obtained crushed product was injection-molded using an injection molding machine (J75E-D manufactured by Nippon Steel Works) at a mold temperature of 80° C. and a mold holding time shown in Tables 1-5. The mold releasability was evaluated with respect to the obtained test piece [a flat plate (70 mm x 40 mm x 3 mm) and a prismatic test piece (125 mm x 12 mm x 6 mm)] according to the following criteria. In addition, the thermal deformation temperature of the prismatic test piece (125 mm x 12 mm x 6 mm) was evaluated by the following method, and the crystallinity of the flat plate (70 mm x 40 mm ...

Embodiment 2-1~2-9、 comparative example 2-1~2-9

[0116] As the biodegradable resin composition, the products of the present invention (2A to 2I) shown in Table 2-1 and the comparative products (2a to 2i) shown in Table 2-2 were used to obtain biodegradable resin compositions in the same manner as in Example 1-1. A pulverized product of a degradable resin composition.

[0117] The obtained pulverized product was dried at 70° C. under reduced pressure for 1 day to reduce the water content to 500 ppm or less.

[0118] table 2-1

[0119]

[0120] Table 2-2

[0121]

[0122] * 1, * 2, * 4 to * 12 is the same as Table 1-1.

[0123] * 3: 12-Hydroxystearic acid triglyceride (manufactured by Kao Corporation, Kao-Waxus 85P)

[0124] Next, the mold holding time was evaluated for the pulverized product obtained above in the same manner as in Example 1-1. In addition, the bleeding resistance of the obtained flat plate (70 mm x 40 mm x 3 mm) was evaluated by the following method. The results are shown in Table 2-3 and Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com