Wind turbine with blade pitch control to compensate for wind shear and wind misalignment

A wind turbine and pitch technology, which is applied to wind turbines, wind turbines, and wind turbine test runs that are consistent with the wind direction, and can solve problems such as slow wind shear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

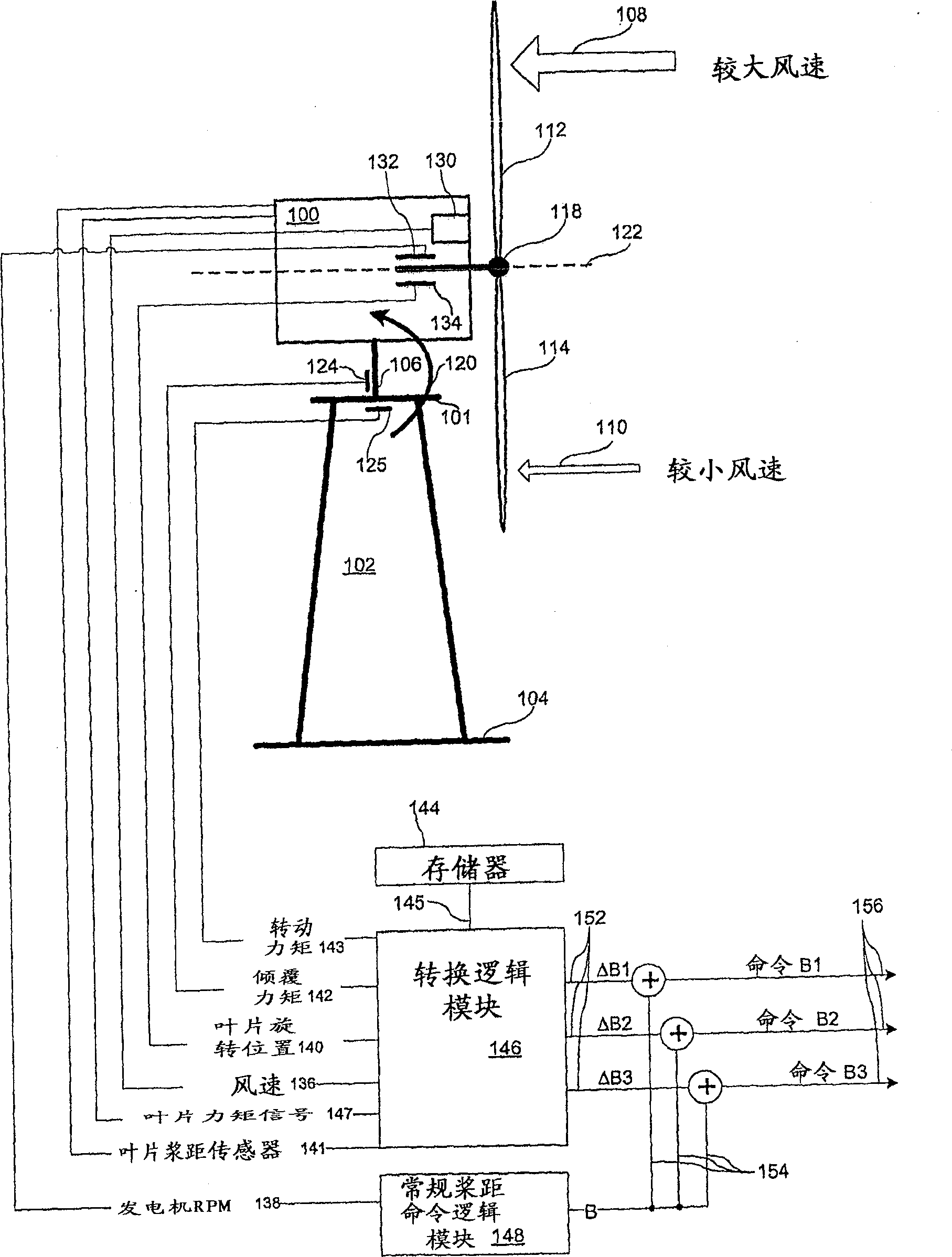

[0043] like figure 1 By way of example, vertical wind shear is the change in wind speed with height above the ground. Among other effects, vertical wind shear is caused by friction with the ground surface which is altitude dependent. The higher the altitude from the ground, the less the effect of surface friction and the higher the wind speed. This phenomenon is usually modeled with a power law function:

[0044] windSpeed∝h α

[0045] Here h is the height above the ground and α is the power exponent, typically 0.14. Actual power exponents vary with local wind conditions and terrain type.

[0046] Because vertical wind shear causes wind speed to vary with altitude, the turbine blades will experience different wind speeds as they rotate around the turbine hub. Periodic changes in wind speed cause periodic changes in the force acting on the blades, causing the blades to flex back and forth and lead to fatigue failure. According to the above formula, the wind speed at heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com