Preparation method of woven compound mail package bags

A technology of weaving and compounding and manufacturing methods, which is applied in the directions of packaging, transportation and packaging, envelope/bag manufacturing machinery, etc., can solve the problems of affecting firmness, complicated production process, and many edges of packaging bags, so as to reduce workload and cut The effect of high efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

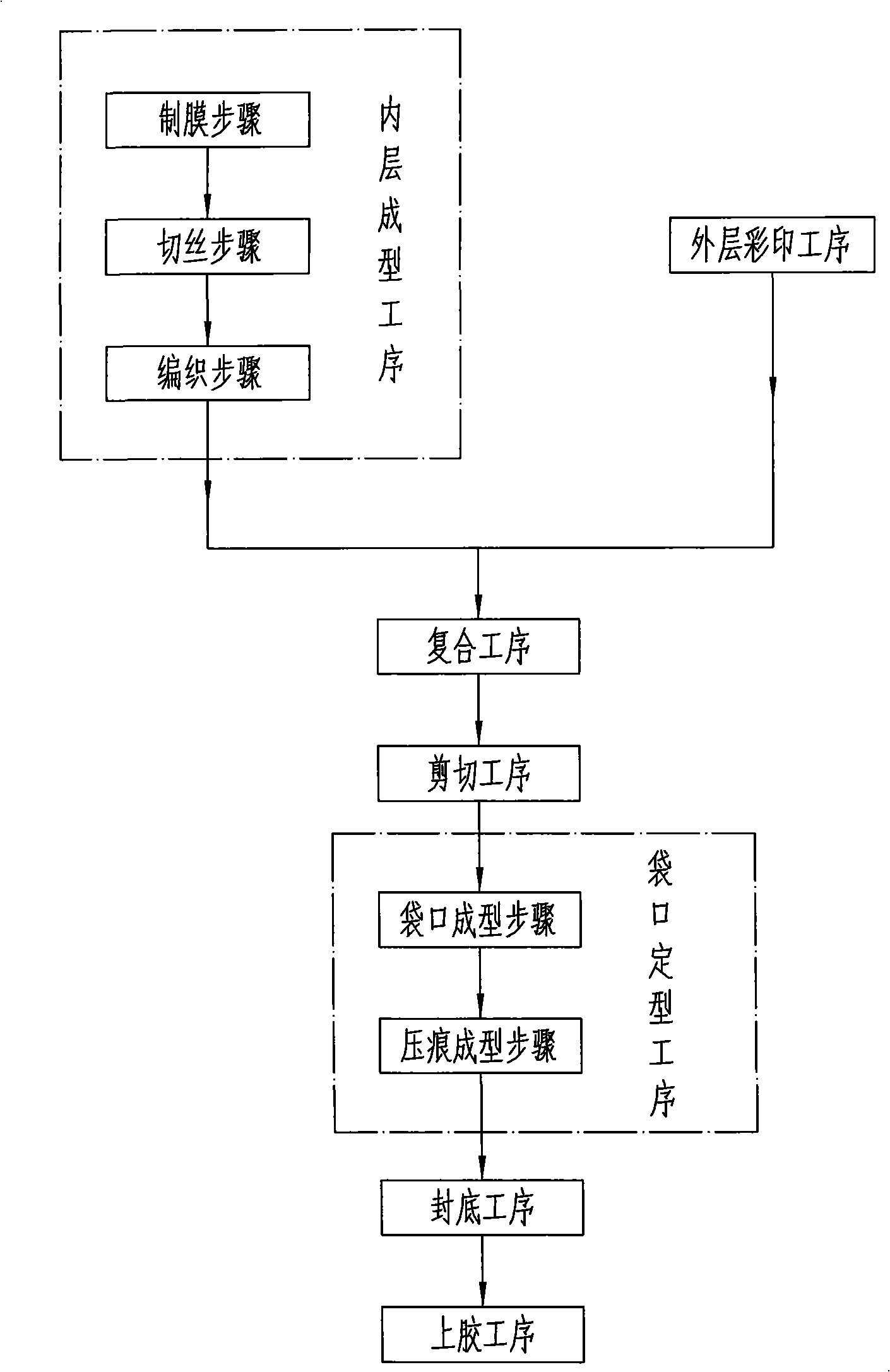

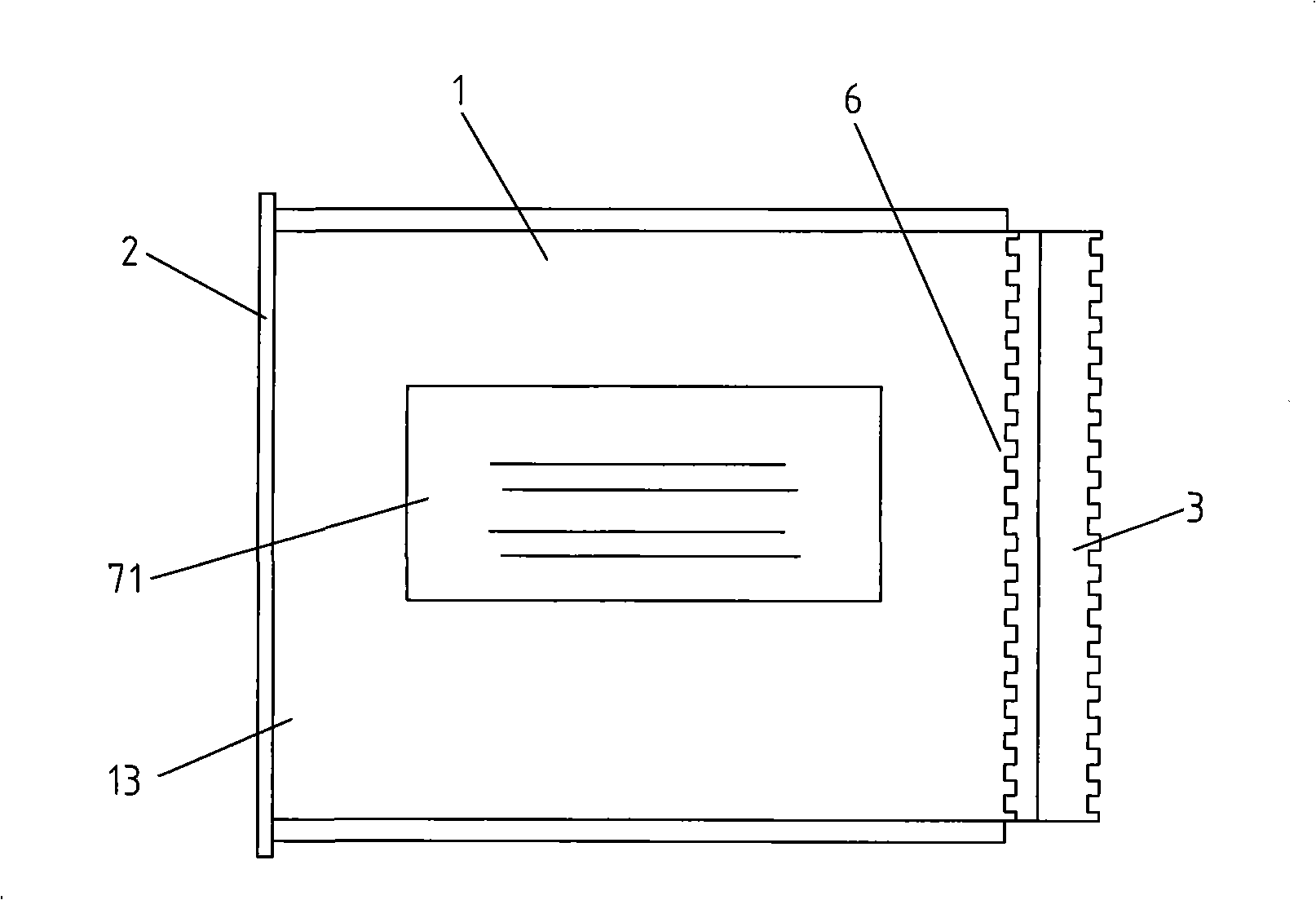

[0042] see Figure 1-Figure 6 , the present invention includes an inner layer forming process, an outer layer color printing process, a composite process, a shearing process, a bag opening shaping process, a back sealing process and a gluing process, wherein the inner layer forming process includes a film making step, a shredding step and a weaving step, The bag mouth shaping process includes a bag mouth forming step and an indentation forming step.

[0043] In the present invention, the inner layer forming process uses plastic particles as raw materials. In this embodiment, the main component of the plastic particles is polypropylene, and the polypropylene plastic particles are prior art. In this embodiment, the polypropylene plastic particles are firstly formed into a film at 240° C., and the performance of the film produced at this temperature is better. The film forming steps in the present invention are the same or similar to those of the prior art. The film forming temp...

Embodiment 2

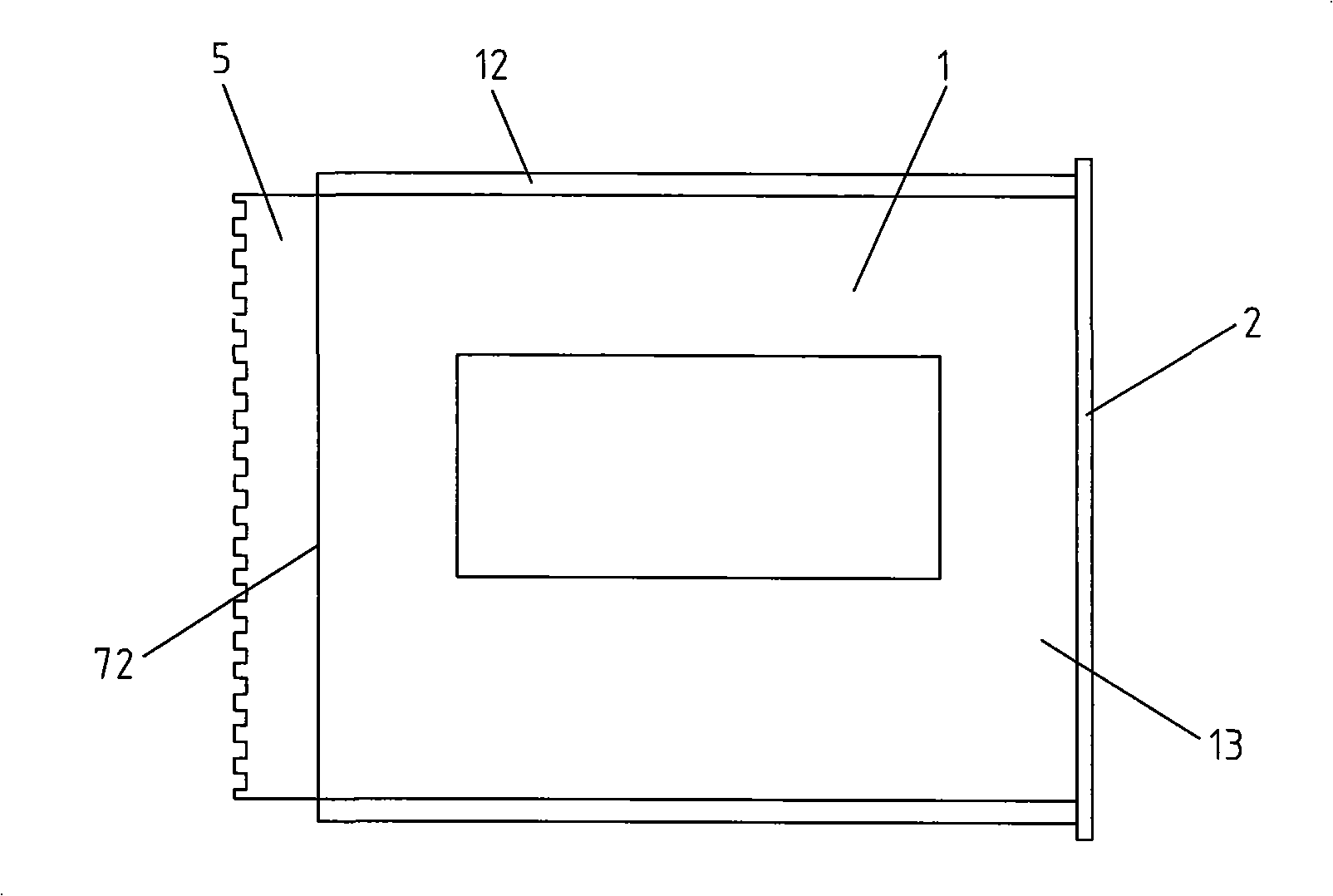

[0056] see Figure 7-Figure 12, the process in this embodiment includes an inner layer forming process, an outer layer color printing process, a composite process, an edge drawing process, a shearing process, a pocket shaping process, a back sealing process and a gluing process, wherein the inner layer forming process includes a film making step , a shredding step and a weaving step, and the pocket opening shaping process includes a pocket opening forming step and an indentation forming step.

[0057] The edge extraction process in this embodiment is located between the composite process and the shearing process. The difference between this embodiment and embodiment 1 is that this embodiment has one more edge extraction process than embodiment 1, and the rest of the present embodiment Procedures are all the same as in Example 1. The inner layer forming process, outer layer color printing process and composite process in this embodiment are the same as those in Embodiment 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com