Method for growing high-quality indium nitride single crystal epitaxial film

A technology of indium nitride single crystal and epitaxial film, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the difficulty of InN single crystal epitaxial film, low ammonia cracking efficiency, low decomposition temperature, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

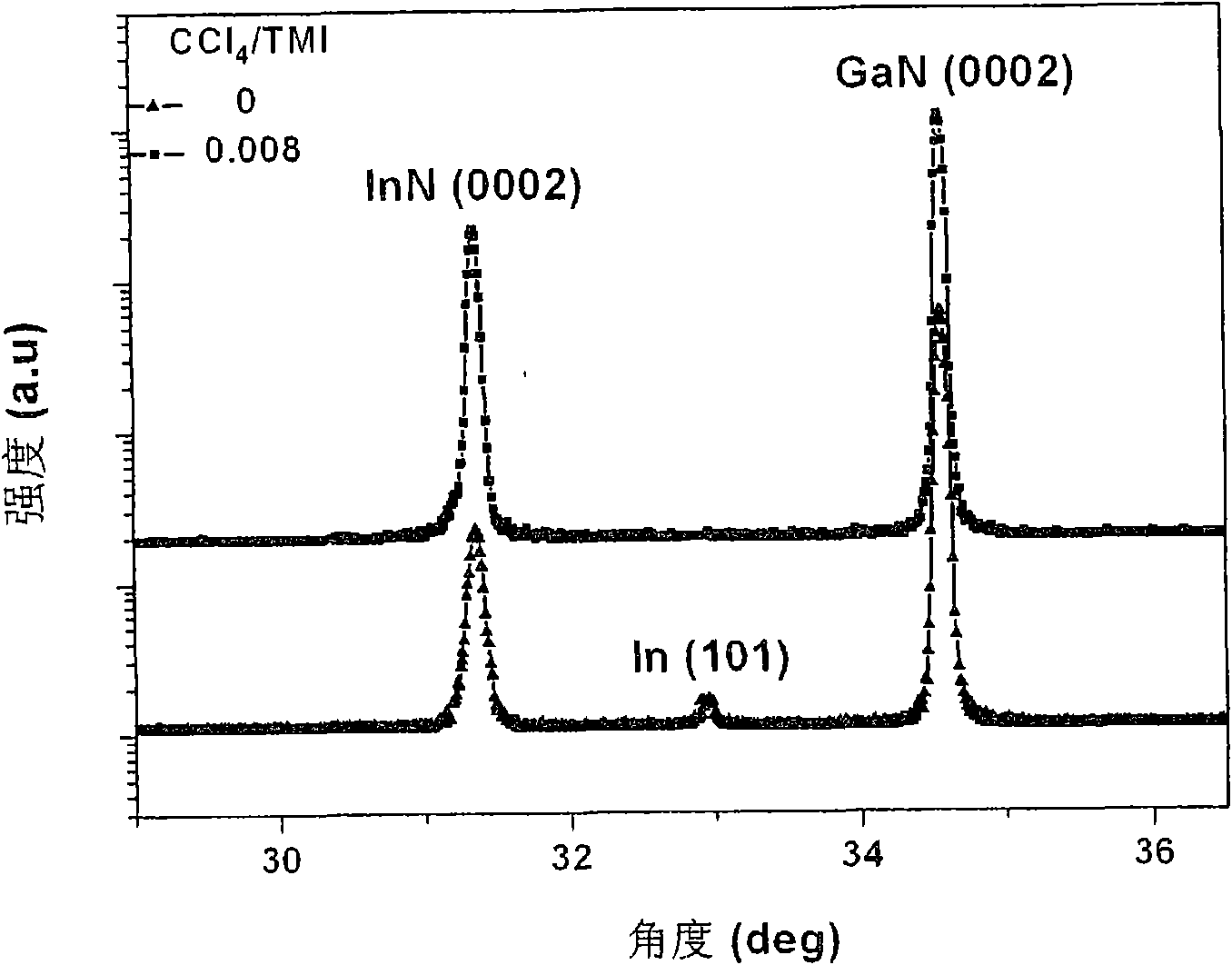

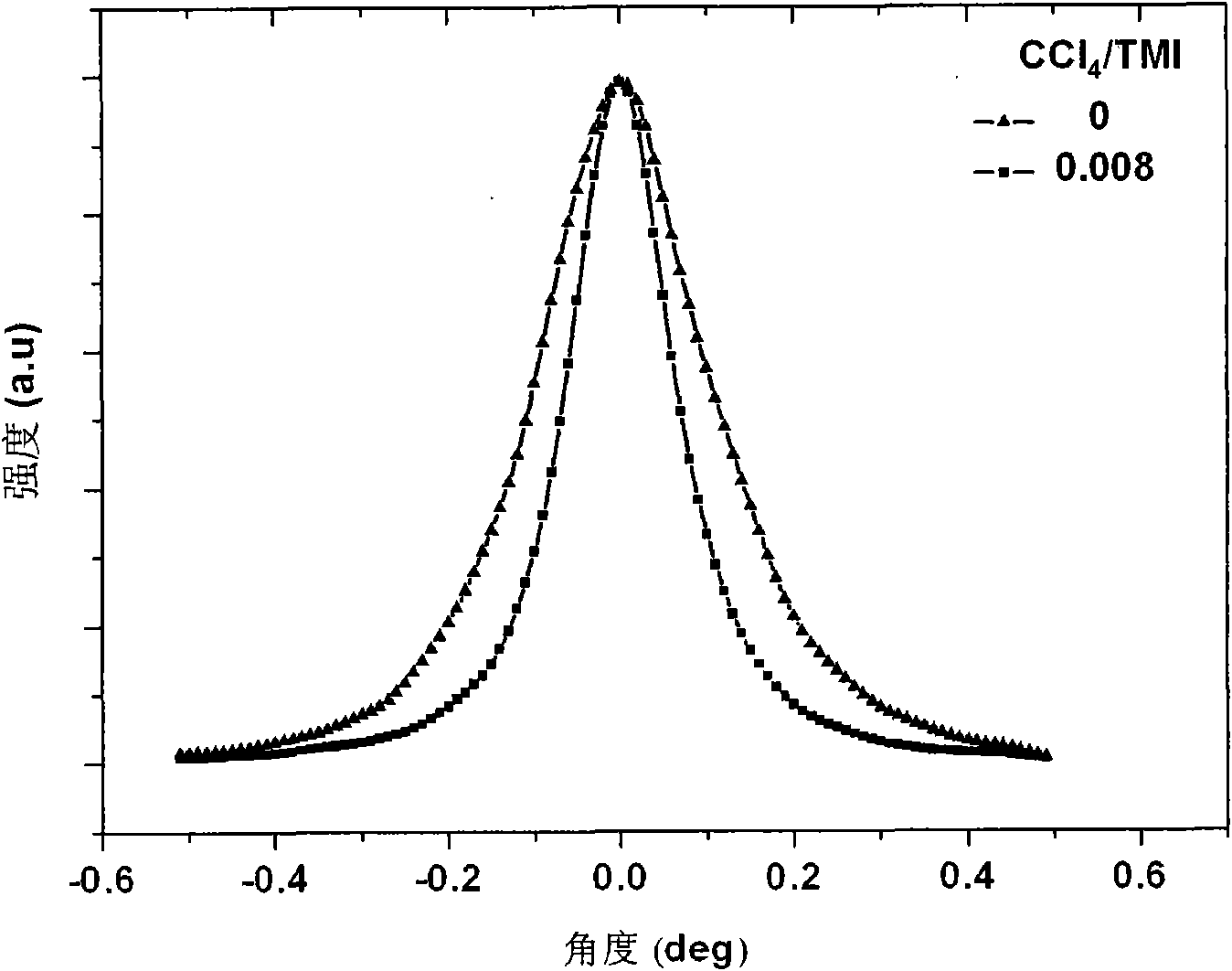

[0019] The key of the invention is to solve the problem of relatively poor crystal quality during the InN heteroepitaxial growth process. Since the decomposition temperature of InN is very low, the growth can only be carried out at a lower temperature, and the cracking efficiency of ammonia gas is very low when MOCVD epitaxy grows InN at a lower growth temperature, and the surface lacks reactive N atoms. Indium drops often appear in the grown InN epitaxial film, and the migration ability of surface adatoms is relatively low, making the InN single crystal epitaxial growth very difficult. In order to solve the problems of indium drops and low surface migration ability during InN epitaxy, the present invention proposes to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com