Method for growing AlInN monocrystal epitaxial film

An epitaxial film and single crystal technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of low migration ability of surface adatoms, affecting applications, uneven components, etc., to achieve enhanced lateral migration ability, Effect of improving crystal quality and improving surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

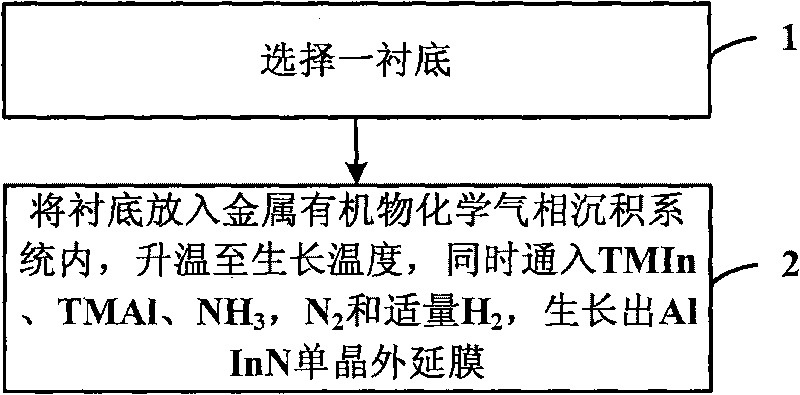

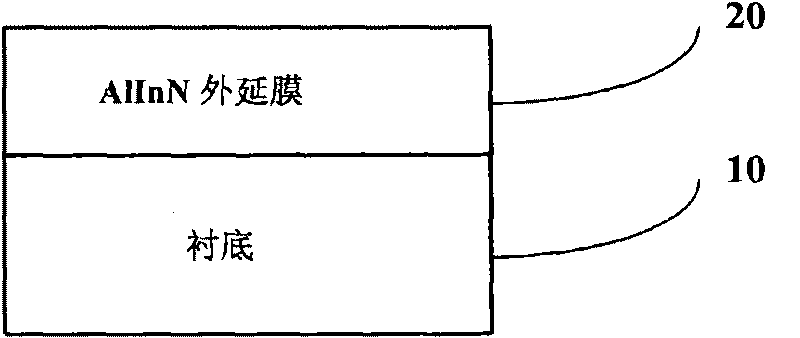

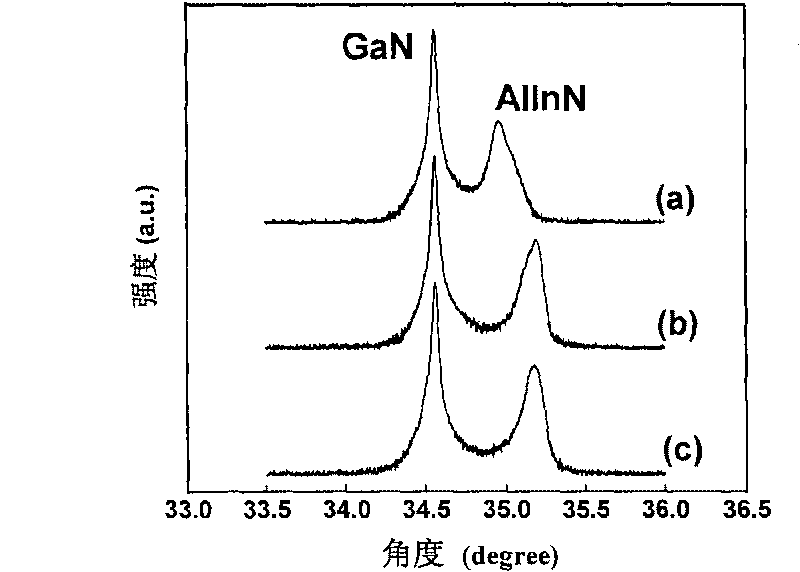

[0028] The key of the invention is to provide a method for growing high-quality AlInN single crystal epitaxial film. Due to the relatively large differences in lattice parameters, bond lengths, and thermal stability between AlN and InN, AlInN is prone to phase separation, resulting in uneven composition. In addition, at a lower growth temperature, the migration ability of surface adatoms is relatively low, especially the adsorbed Al atoms, making it difficult to grow high-quality AlInN single crystal epitaxial films. In order to solve the problems of easy phase separation and low surface migration ability during the growth of AlInN, the present invention proposes to use nitrogen and an appropriate amount of hydrogen as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com