Automatic heat insulation assembly process of multilayer composite fibre wall body outer wall

A multi-layer composite and assembly process technology, applied in walls, building materials, building components, etc., can solve the problems of lack of sound insulation and fire prevention, heat preservation and energy saving, light weight, complicated and cumbersome installation of external wall processes, and large volume of end products, etc. Construction flexibility, easy and fast installation, light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

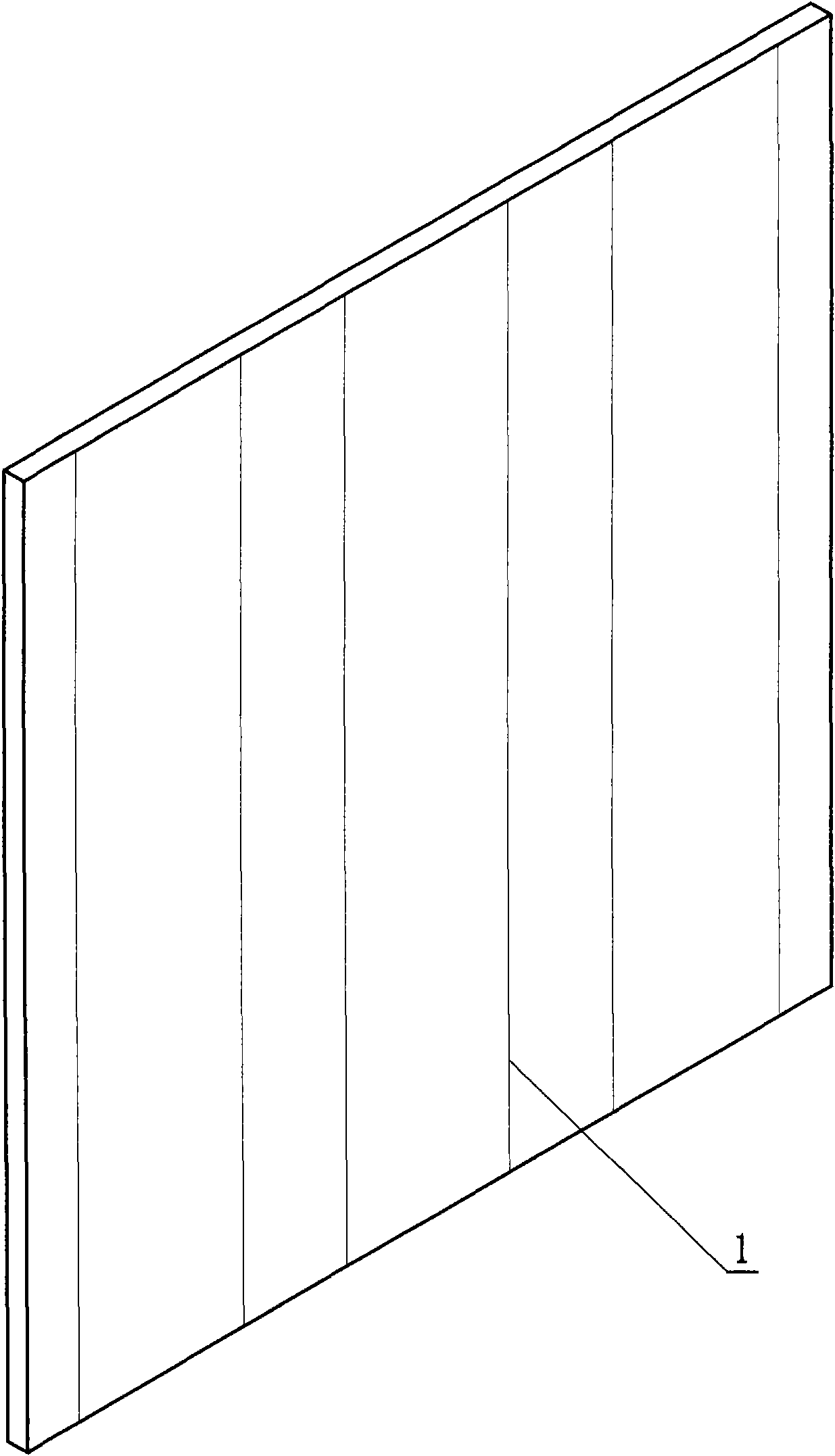

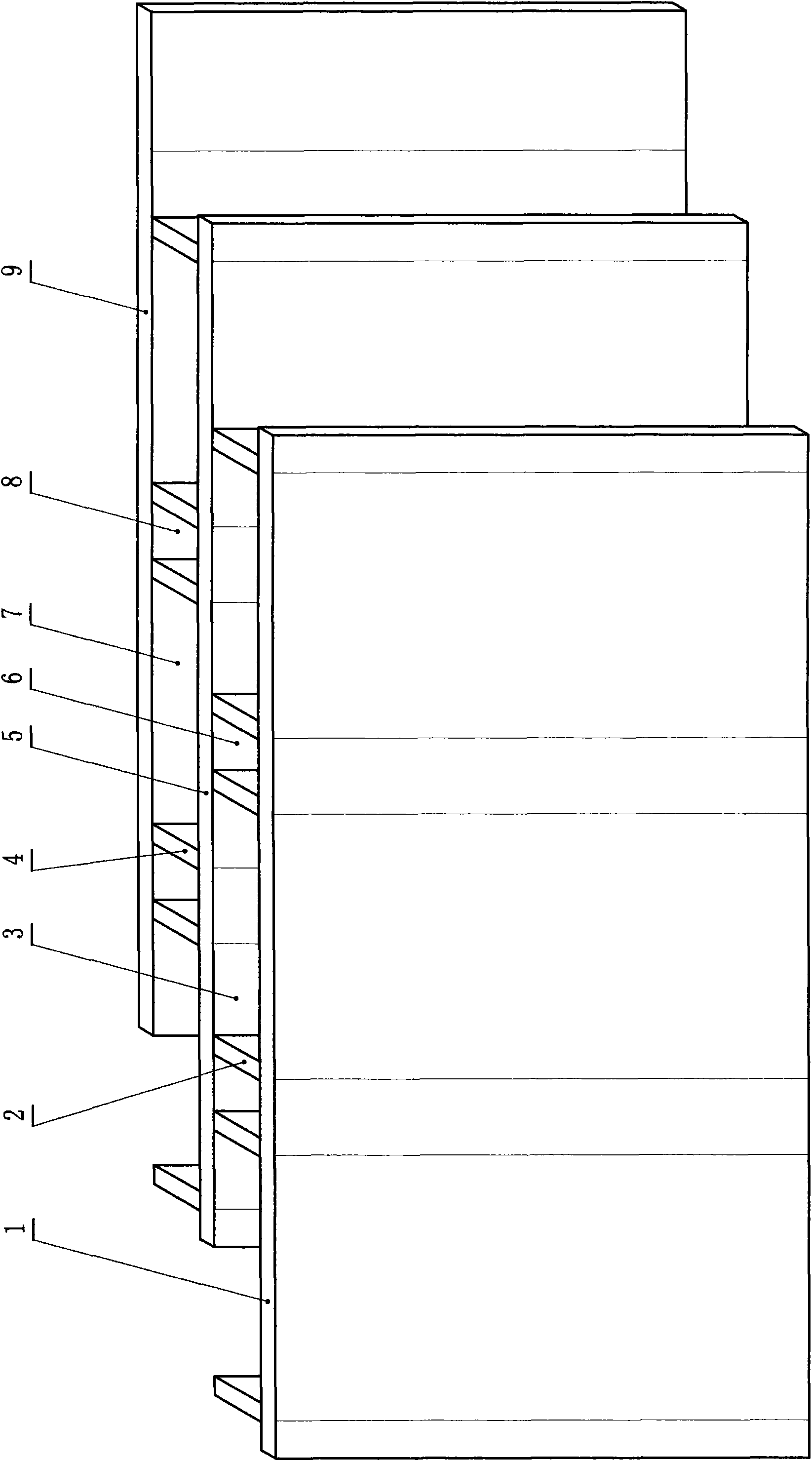

[0011] Such as image 3 The wall body formed by the assembly of the inner layer board, the middle board, the outer layer board and the keel bar has strong thermal insulation and energy saving performance, and can be used for the self-insulation outer wall of the building. In the above-mentioned implementation process, the sound insulation and heat insulation cotton is filled in the panel as required, which can enhance the sound insulation and heat insulation effect of the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com