Method for repairing mask plate

A repair method and reticle technology, applied in the field of reticle repair, can solve the problem of not being able to find a reproducible graphic, and achieve the effect of low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the reticle repair method of the present invention will be described in detail below with reference to the accompanying drawings.

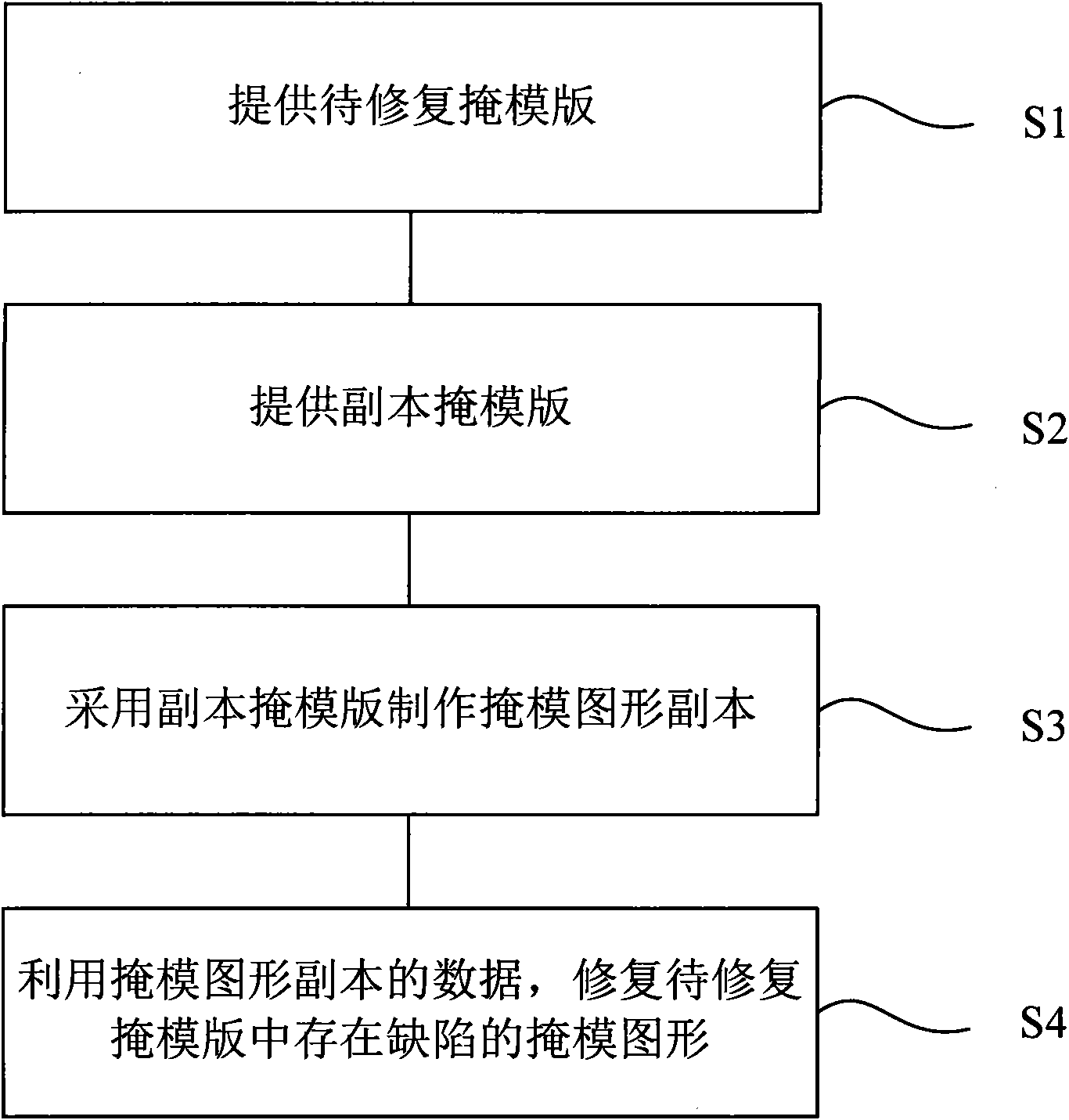

[0024] as attached figure 1 Shown is the flow chart of the implementation steps of the specific embodiment of the reticle repair method. Including the following steps: step S1, providing a reticle to be repaired; step S2, providing a duplicate reticle; step S3, using the duplicate reticle to make a mask pattern replica; step S4, using the data of the mask pattern replica to repair the to-be-repaired reticle There are defects in the mask pattern.

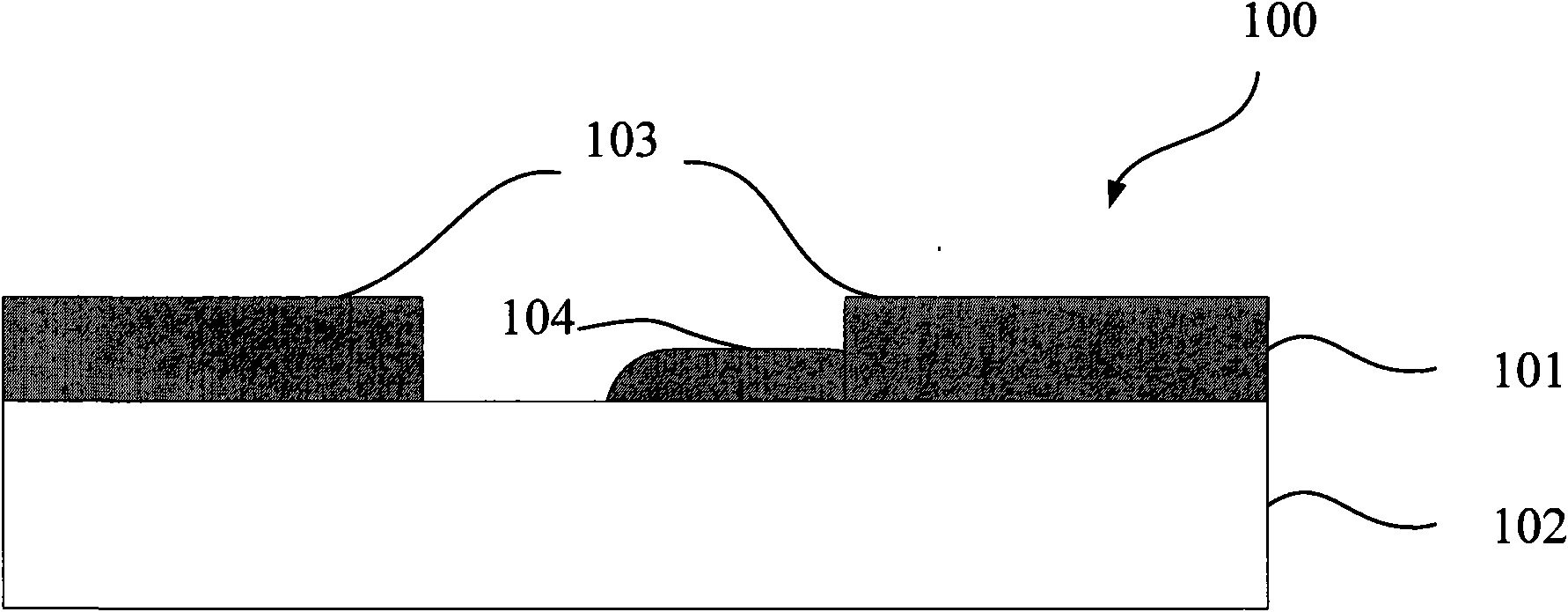

[0025] as attached figure 2 As shown, referring to step S1, a reticle 100 to be repaired is provided. The reticle 100 to be repaired includes a light shielding layer 101 and a substrate 102 . A mask pattern 103 is formed on the light shielding layer, and defects 104 exist in the mask pattern 103 .

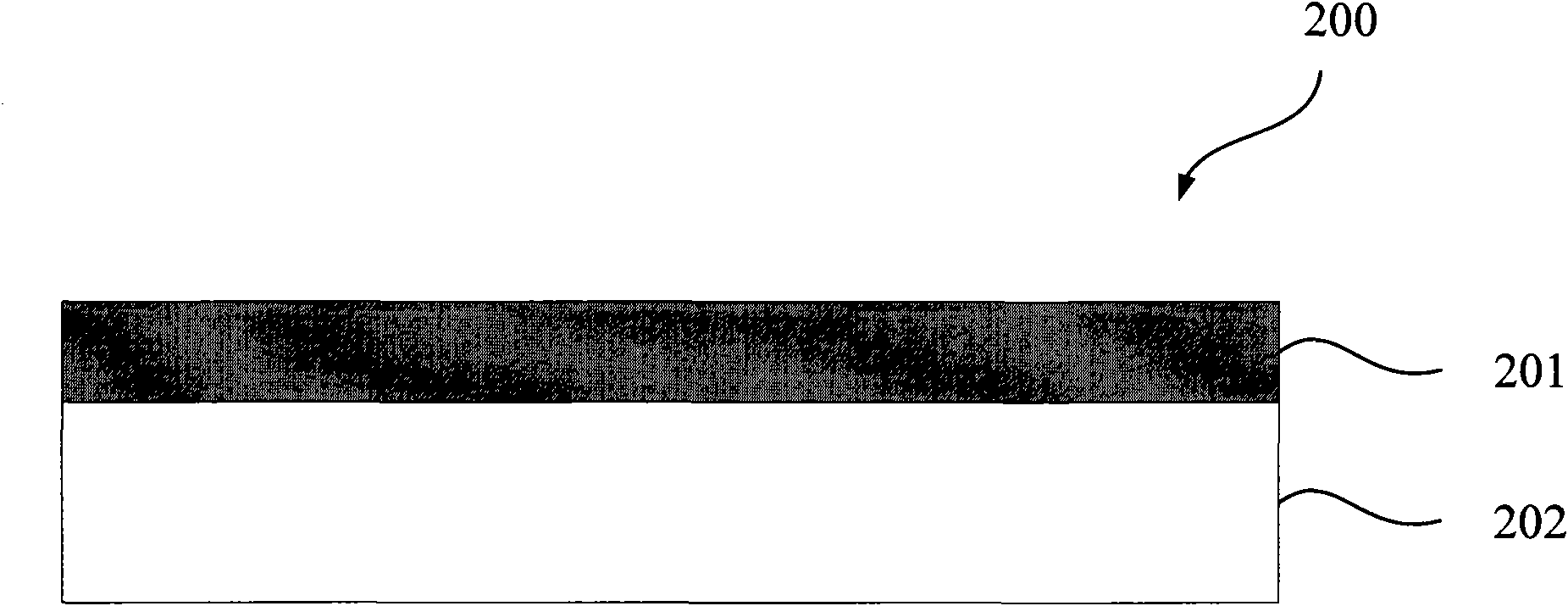

[0026] as attached image 3 As shown, referring to step S2, a re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com