Computer-assisted forming method of steel arch with wave webs

A computer-aided, wavy web technology, applied in computer control, instruments, simulators, etc., can solve problems such as web buckling deformation, large scraps, and unusability, and achieve improved out-of-plane rigidity, raised stiffness, and energy saving The effect of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

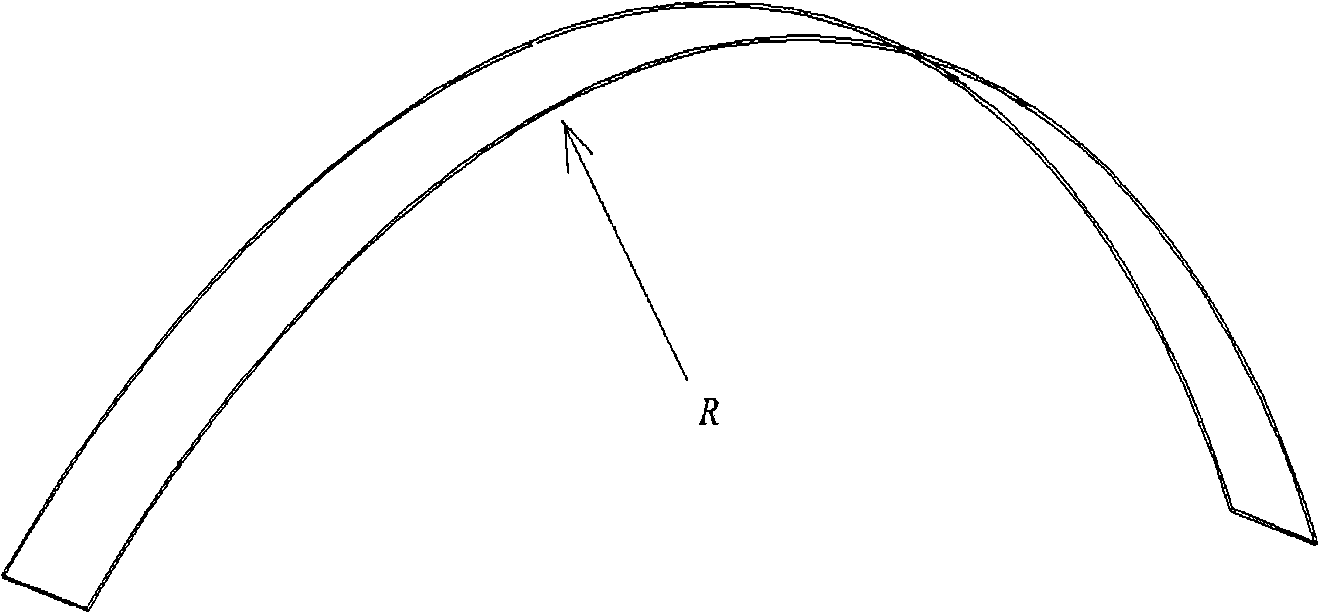

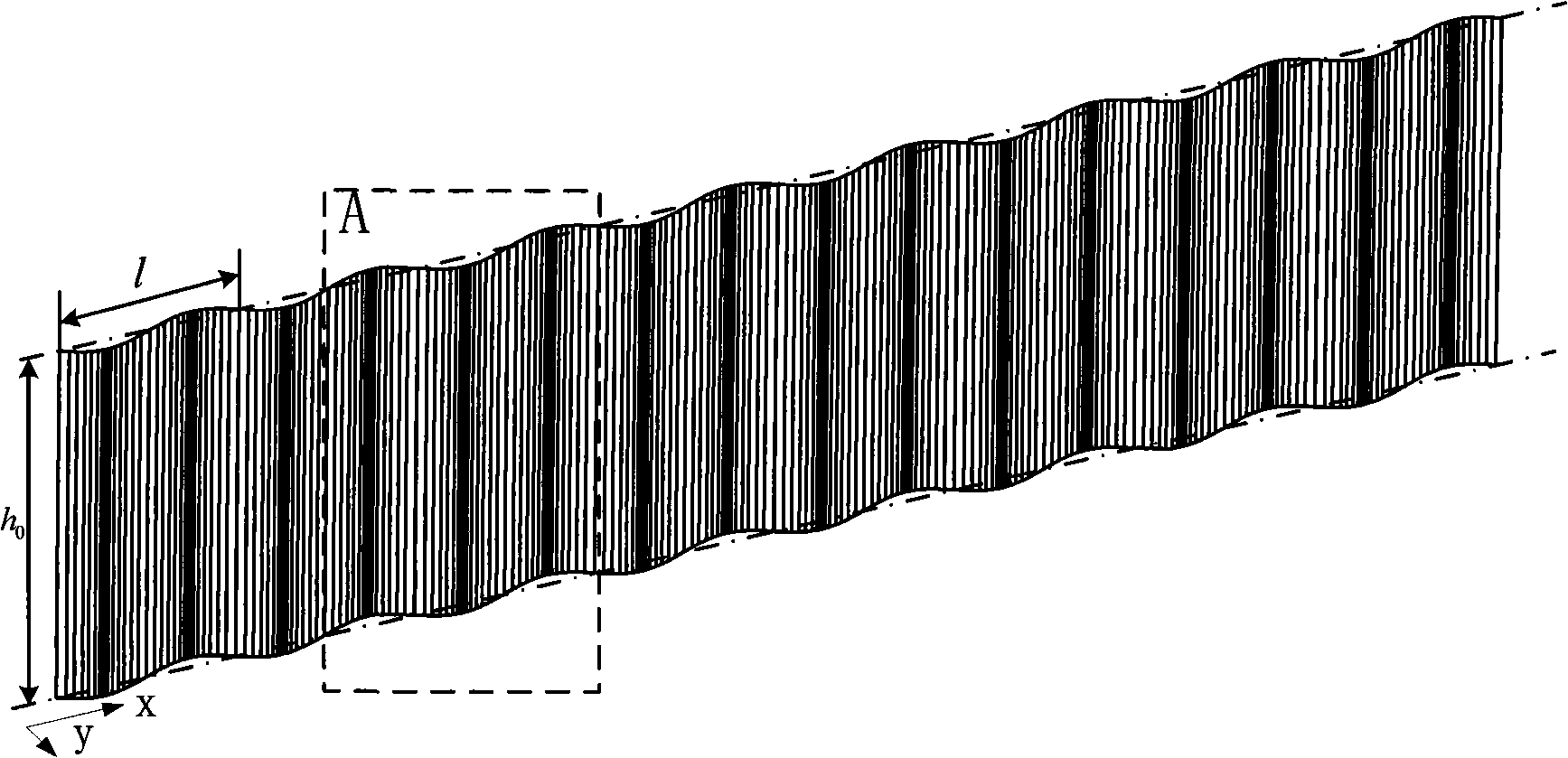

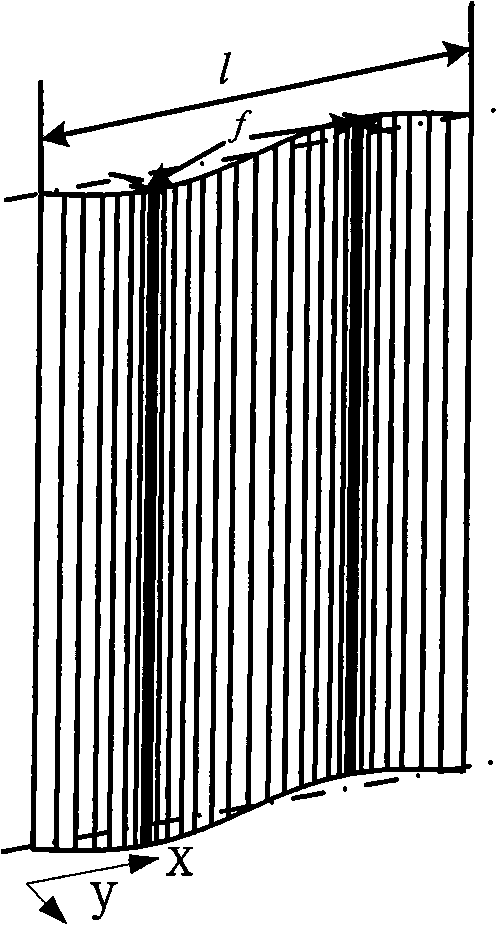

[0054] The invention proposes a computer-aided forming method for a corrugated web steel arch, and its computer-aided control system is divided into five control modules, which respectively correspond to the five steps of corrugated web forming. Firstly, in the first control module, that is, the blanking module, the rectangular flat web and the upper and lower flange plates are cut according to a specific size, and then the upper and lower flange plates are cold-bent into the upper and lower flange arch plates in the second control module. In the third control module, the rectangular strip web is rolled into a uniform wavy web, and then in the fourth control module, the rectangular uniform wavy web is rolled into an upper and lower non-uniform wavy arc web, along the lower wing The indentation of the web area on the side of the flange is deepened, and the indentation of the web area on the side of the upper flange is elongated, so that the web automatically forms an arch, and f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap