Scrap steel crusher

A shredder and steel scrap technology, which is applied in metal processing, grain processing, high internal friction springs, etc., can solve the problems of small processing range, inability to deal with scrapped cars, large light and thin scraps of household appliances and mixed scraps, etc., and achieve improvement Production efficiency, expanding the range of processed materials, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

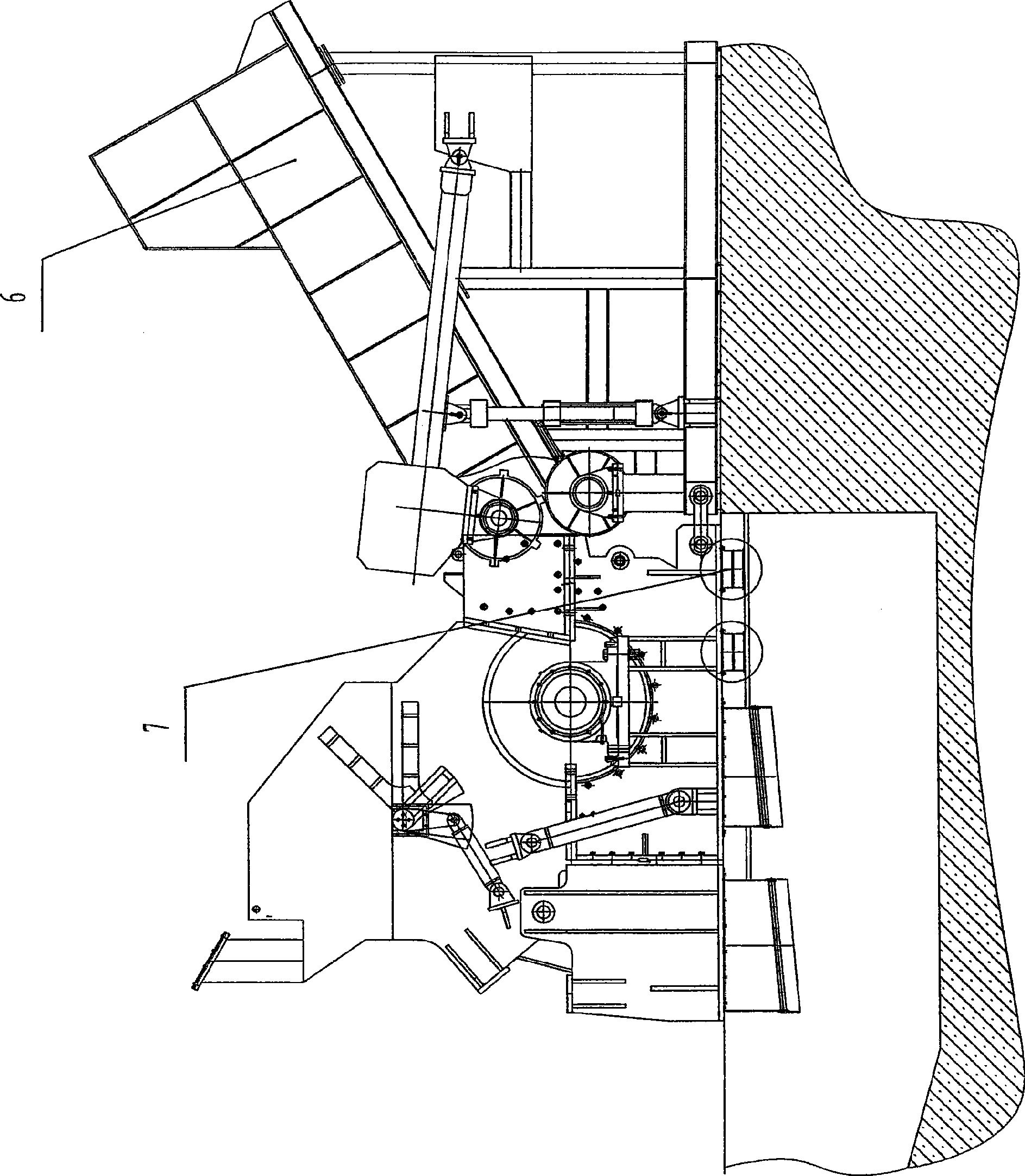

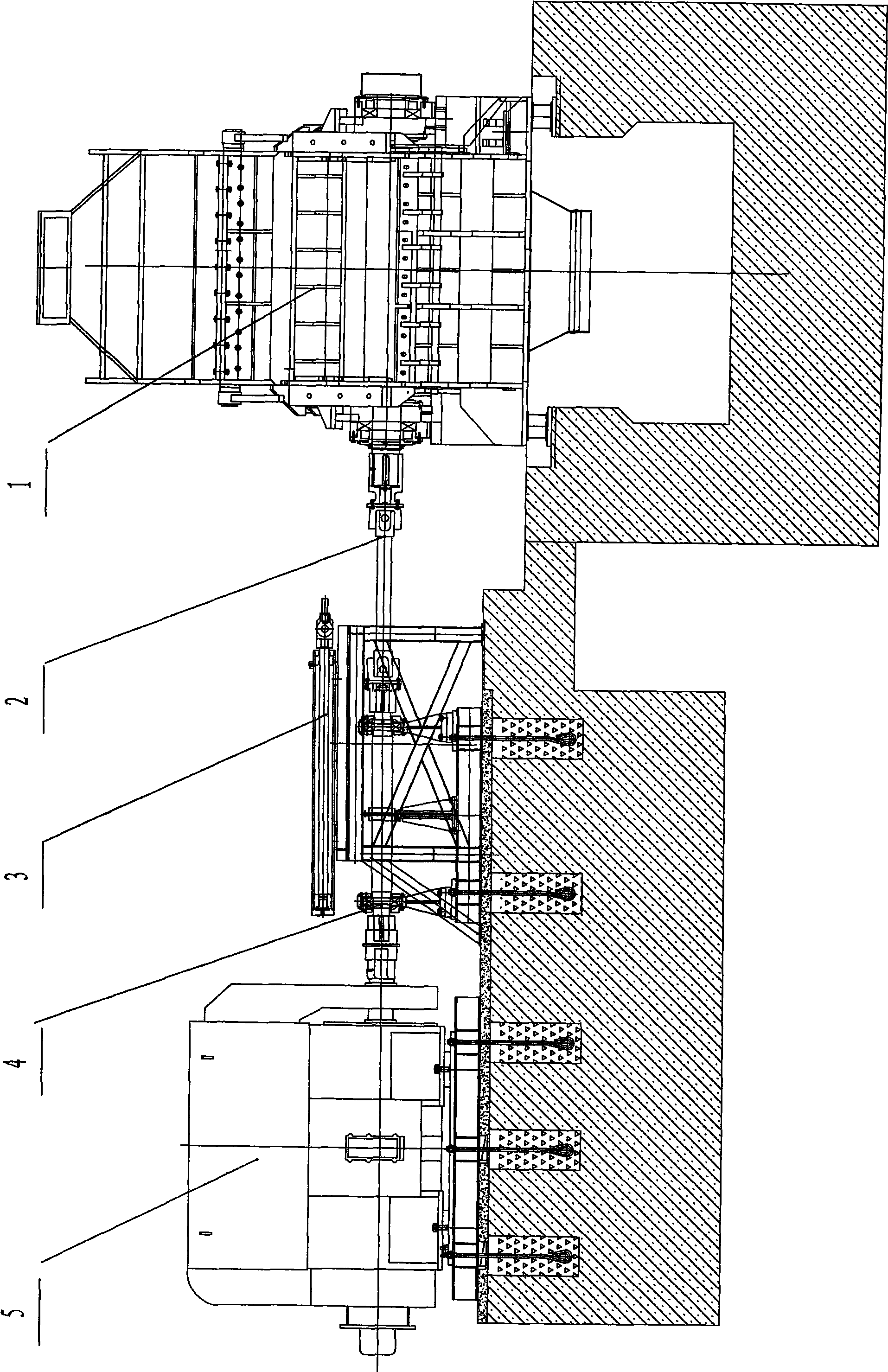

[0042] see Figure 1~2 , The steel scrap crusher involved in the present invention is mainly composed of a feeder 6 with hydraulic double drums, a crusher host 1, a shock absorber 7, a cardan shaft 2, a connecting main shaft 4, an electric motor 5 and a pin puller 3.

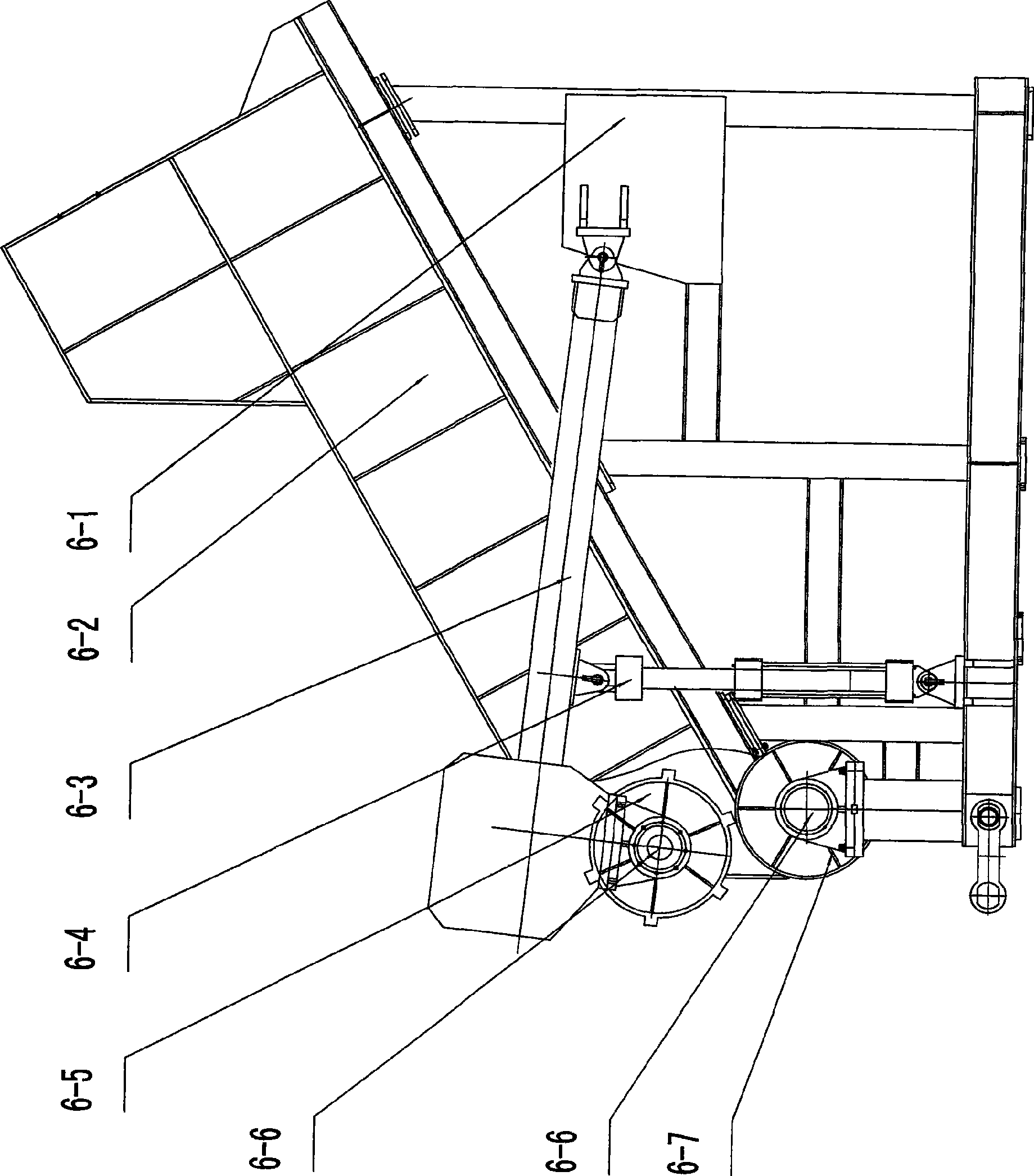

[0043] see image 3, the feeder 6 with hydraulic double drums is placed on the front side of the main crusher 1, and consists of a support 6-1, a chute 6-2, an upper drum lifting arm 6-3, a compression cylinder 6-4, The upper pressing roller 6-5, the hydraulic motor 6-6 and the lower pressing roller 6-7 are composed. The bracket 6-1 is placed on the front side of the crusher host 1, the chute 6-2 is obliquely arranged on the bracket 6-1, and the front end of the upper roller lifting arm 6-3 is rotatably connected to the front of the bracket 6-1. The side of the upper part, the middle is hinged with the piston rod of the compression cylinder 6-4, the cylinder tail of the compression cylinder 6-4 is hinged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com