Chassis under limited conditions

A technology of extreme working conditions and vehicle chassis, which is applied in the direction of vehicle components, substructure, elastic suspension, etc., can solve the problems of no guarantee for the life safety of drivers and passengers, affect the driving safety of the vehicle, and poor driving stability, etc., to achieve Reduce the possibility of tail drift, ensure life safety, and optimize the effect of front and rear axle load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

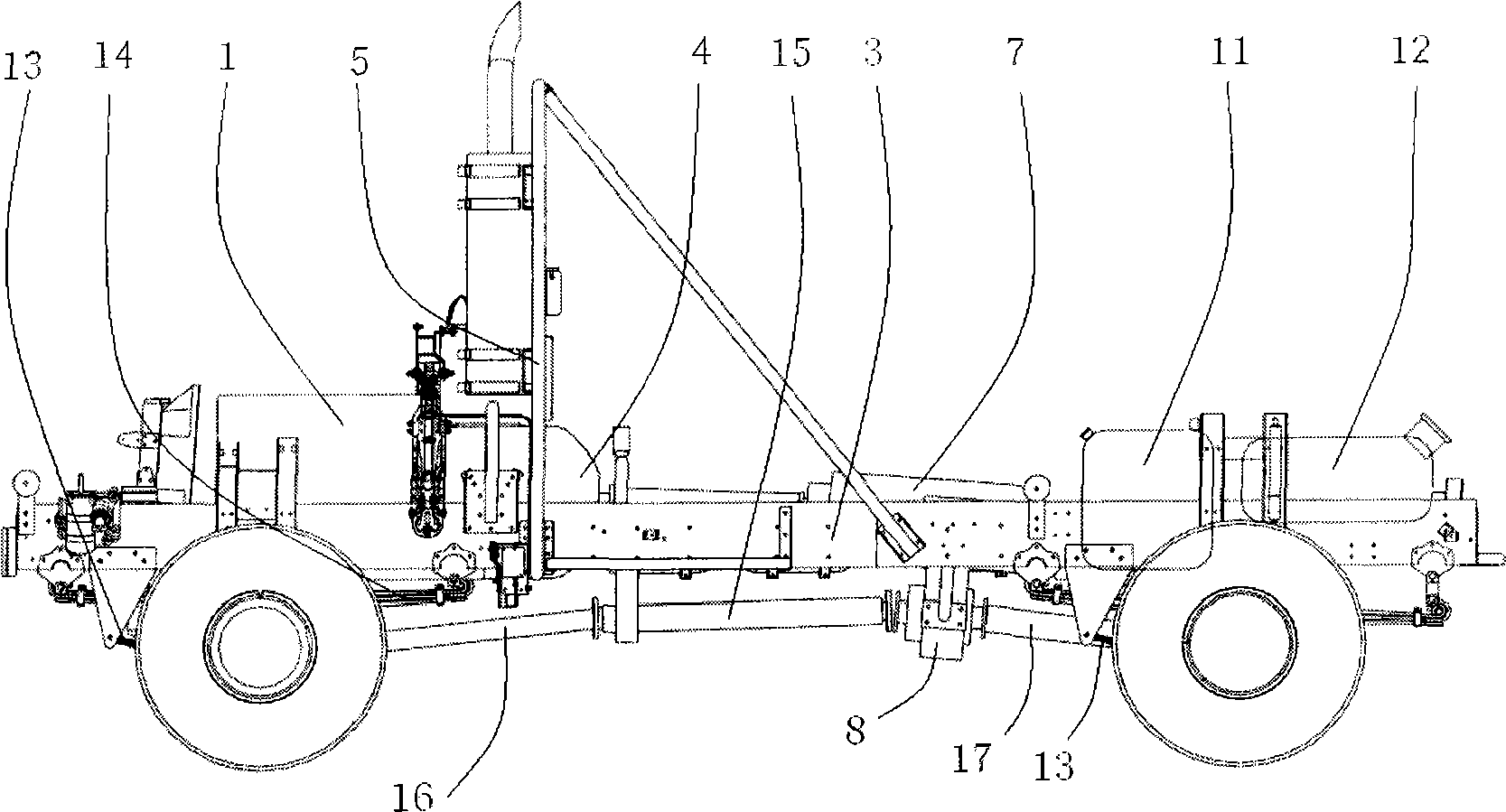

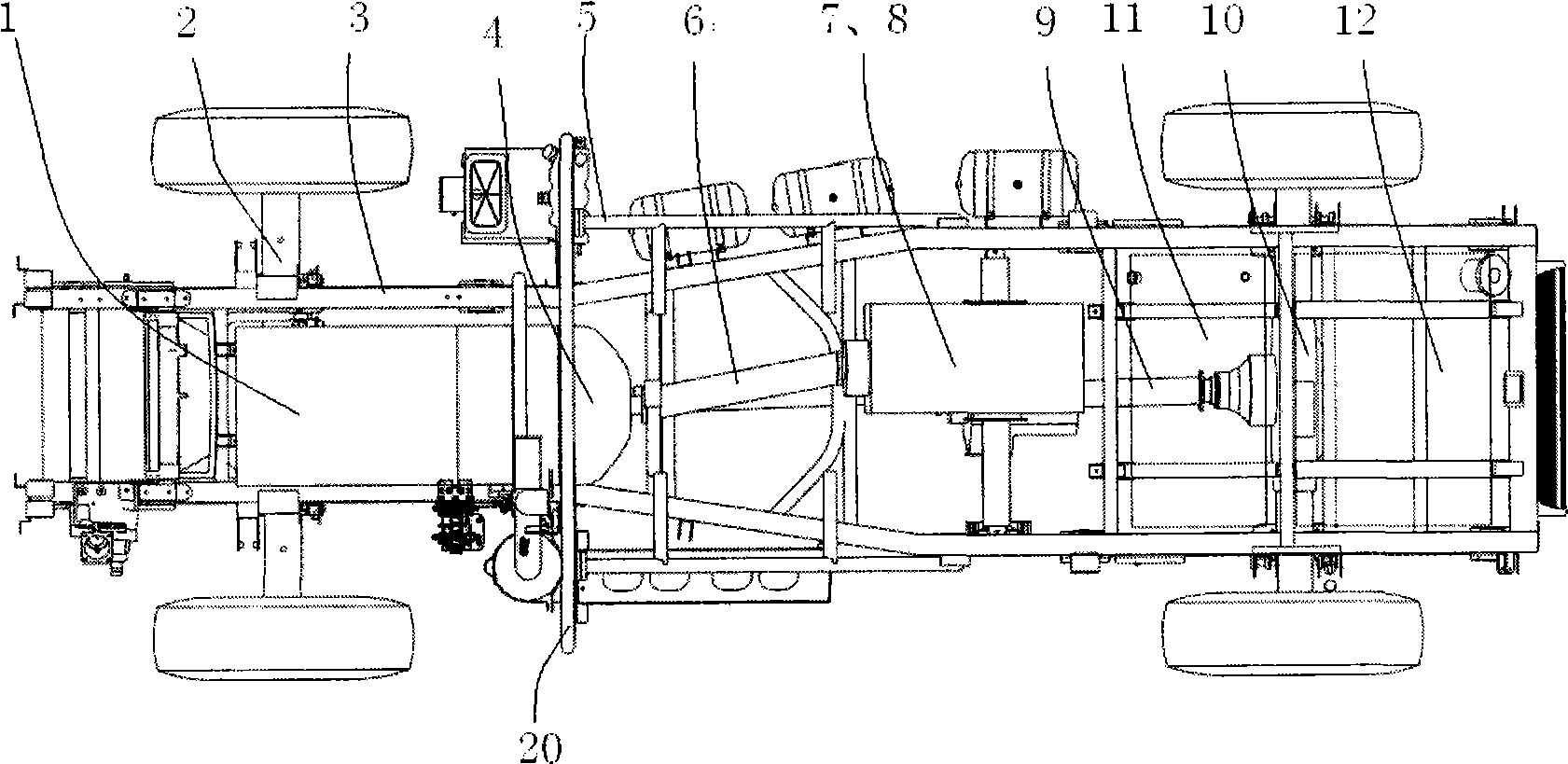

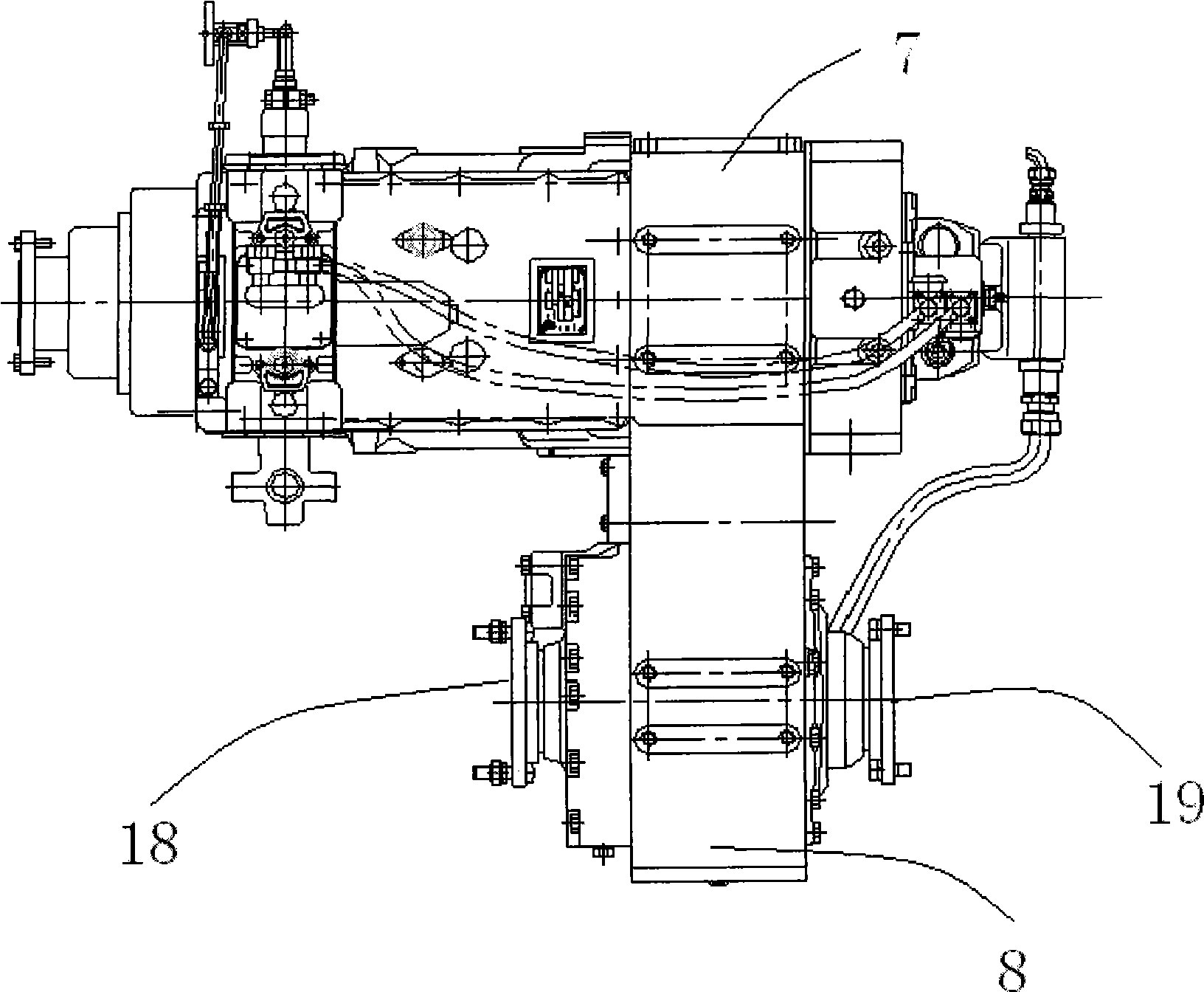

[0020] The extreme working condition vehicle chassis of the present invention will be further described in detail below in conjunction with the embodiments shown in the accompanying drawings. The extreme working condition vehicle chassis of the present invention mainly comprises vehicle frame 3, automobile engine 1, automobile clutch 4 with flange output, leaf spring 14 with few leaf springs of thrust rod 13, gearbox 7, transfer case 8, Chassis roll cage 5, and main fuel tank 11 and auxiliary fuel tank 12. Vehicle frame 3 is front narrow rear wide structure, and vehicle engine 1 and front axle 2 are installed in the narrower part of vehicle frame front end, rear axle 10 is installed in the wider automobile part of rear end, and the output end of automobile engine 1 is fixedly installed with belt The automobile clutch 4 output by the flange; the gearbox 7 is integrated with the transfer case 8, the gearbox 7 is located in the middle of the frame, and is connected with the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com