Connecting device of fast-assembling light road slab

A connecting device and road slab technology, which is applied in the direction of roads, roads, special pavement, etc., can solve the problems of road slab damage, failure to lay double layers, easy to be stuck by sand and other materials, etc., to achieve perfect functions, convenient disassembly and Installation and private storage are high in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The accompanying drawings show the embodiments of the present invention, and the embodiments of the present invention are further described below with reference to the accompanying drawings, but are not intended to limit the present invention.

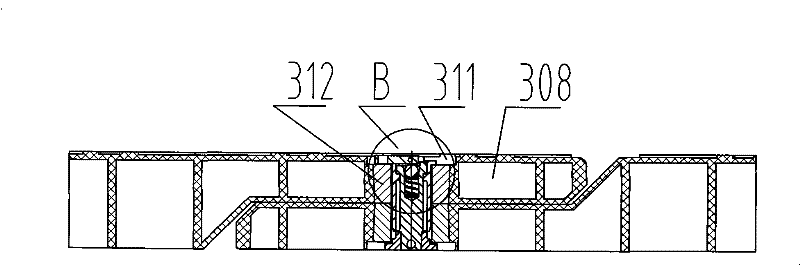

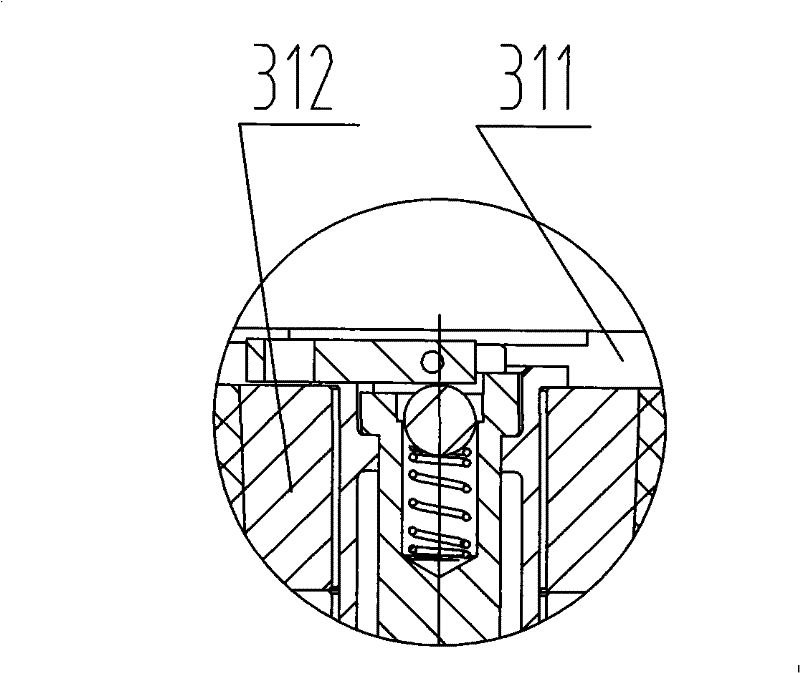

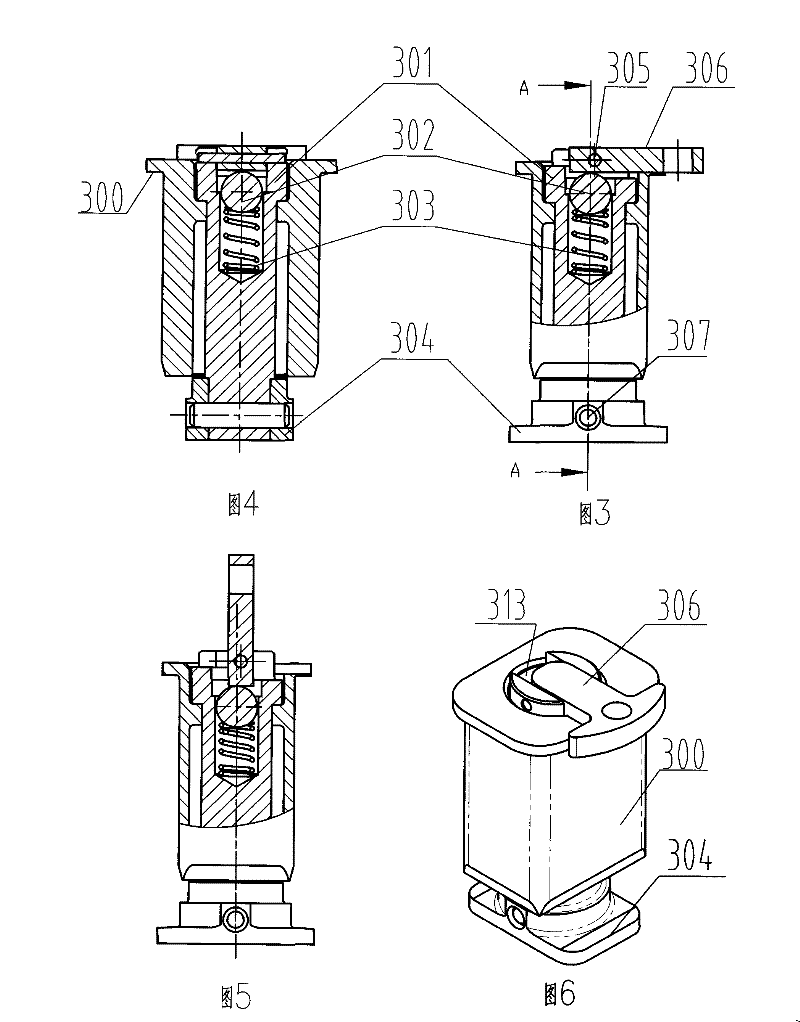

[0035] The overall structure of this embodiment is shown in the figure, which includes mounting holes 311 opened on the surface of the light-weight pavement board 308 , and connecting members are penetratingly connected between the corresponding mounting holes 311 on the adjacent pavement boards 308 , and the mounting holes 311 The inner wall is bonded and fixed with a pre-embedded sleeve 312 , and the connecting member includes a casing 300 , which is slidingly matched with the inner wall of the pre-embedded sleeve 312 , and whose top bulges and is clamped with the upper end of the inner hole of the pre-embedded sleeve 312 , and is arranged on the casing 300 . A rotating shaft 301 with its inner cavity and its outer circumferenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com