A stamping connector and its light steel structure stiff frame

A technology of stamping connections and connectors, which is applied in the field of light steel structural rigid frames, can solve the problems of large cost of materials and many self-tapping screws, and achieve the effects of improving the overall bearing capacity, beautiful appearance, and increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

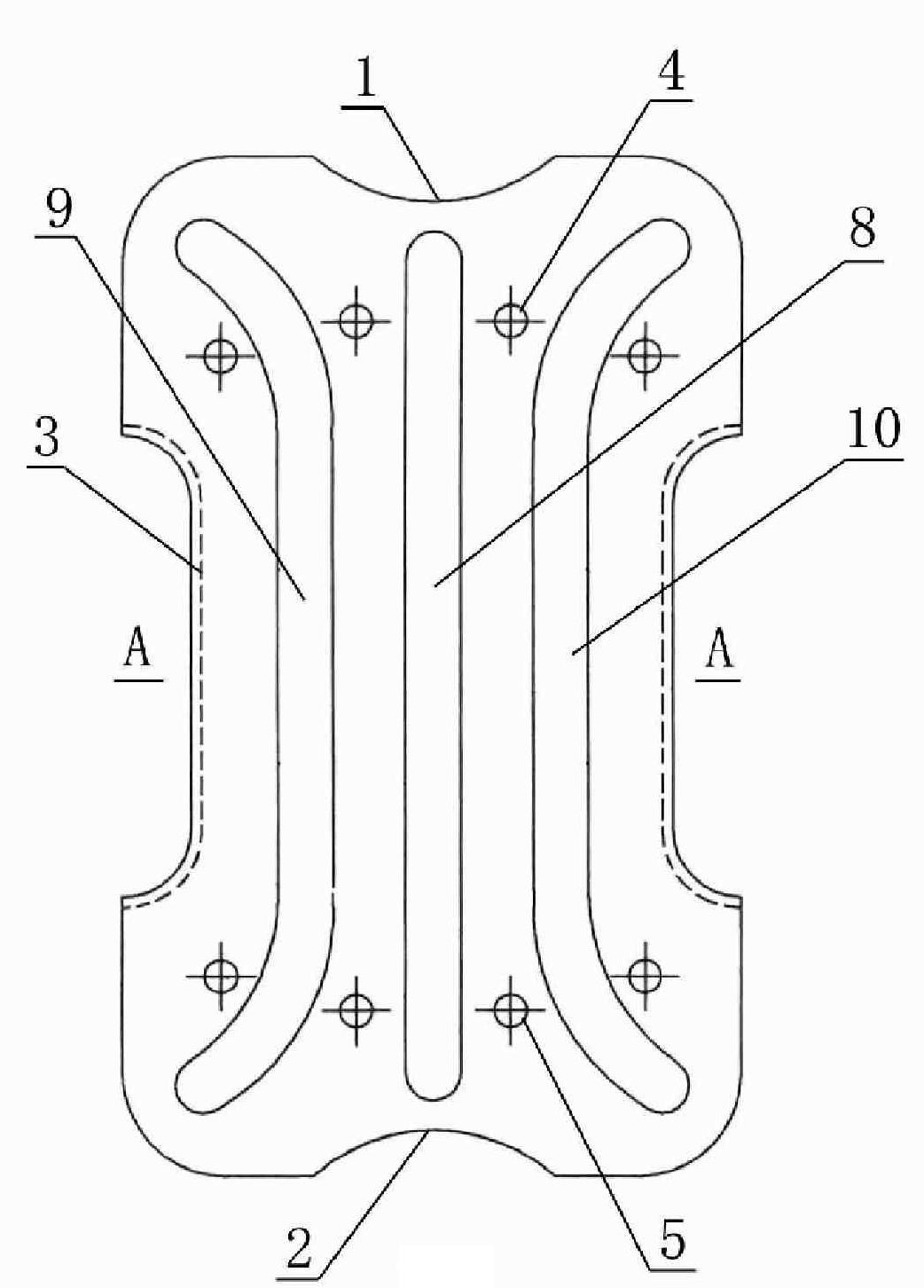

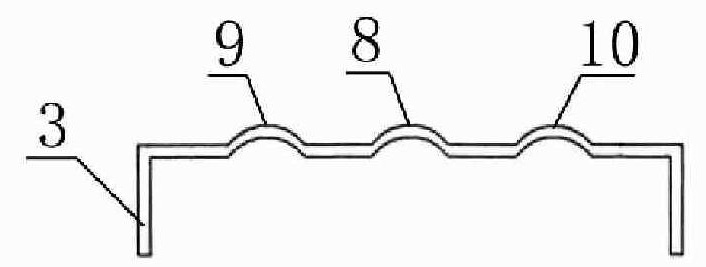

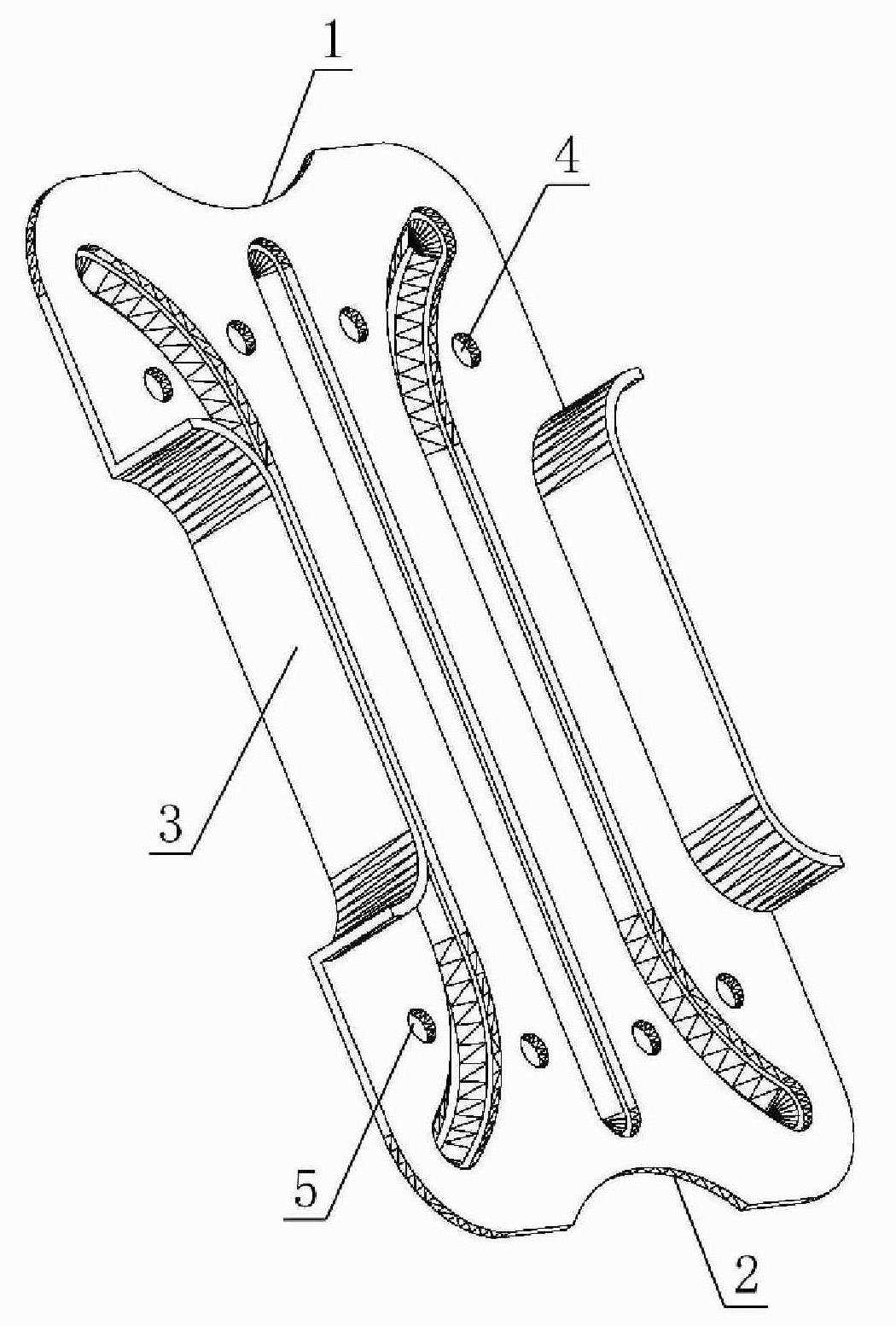

[0030] Examples see Figure 1-5 As shown, this stamped connector is a plate-shaped integral connector stamped from a steel plate. There is an upper arc-shaped gap 1 in the middle of the upper edge of the plate-shaped integral connector, and the lower edge of the plate-shaped integral connector There is a lower arc-shaped gap 2 in the middle position, and the middle position of the left and right sides of the steel plate is concave, and the concave edge has a flange flange 3 that is perpendicular to the plate surface and bends toward the back of the steel plate. On the front of the steel plate, from top to bottom, there is at least one arc-shaped convex streak on the front of the steel plate, such as two, three, four, or five streaks. In this example, there are three arc-shaped convex streaks on the front of the steel plate. , wherein the streak 8 in the middle is a straight strip, the left and right streaks are symmetrical, the upper end of the left streak 9 bends to the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com