Light slat anti-crack construction method

A construction method and slat technology, applied in building components, building thermal insulation materials, etc., can solve the problems of cracking of board seams and easy cracking of board seams, so as to ensure the installation quality and solve the effect of cracking of board seams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

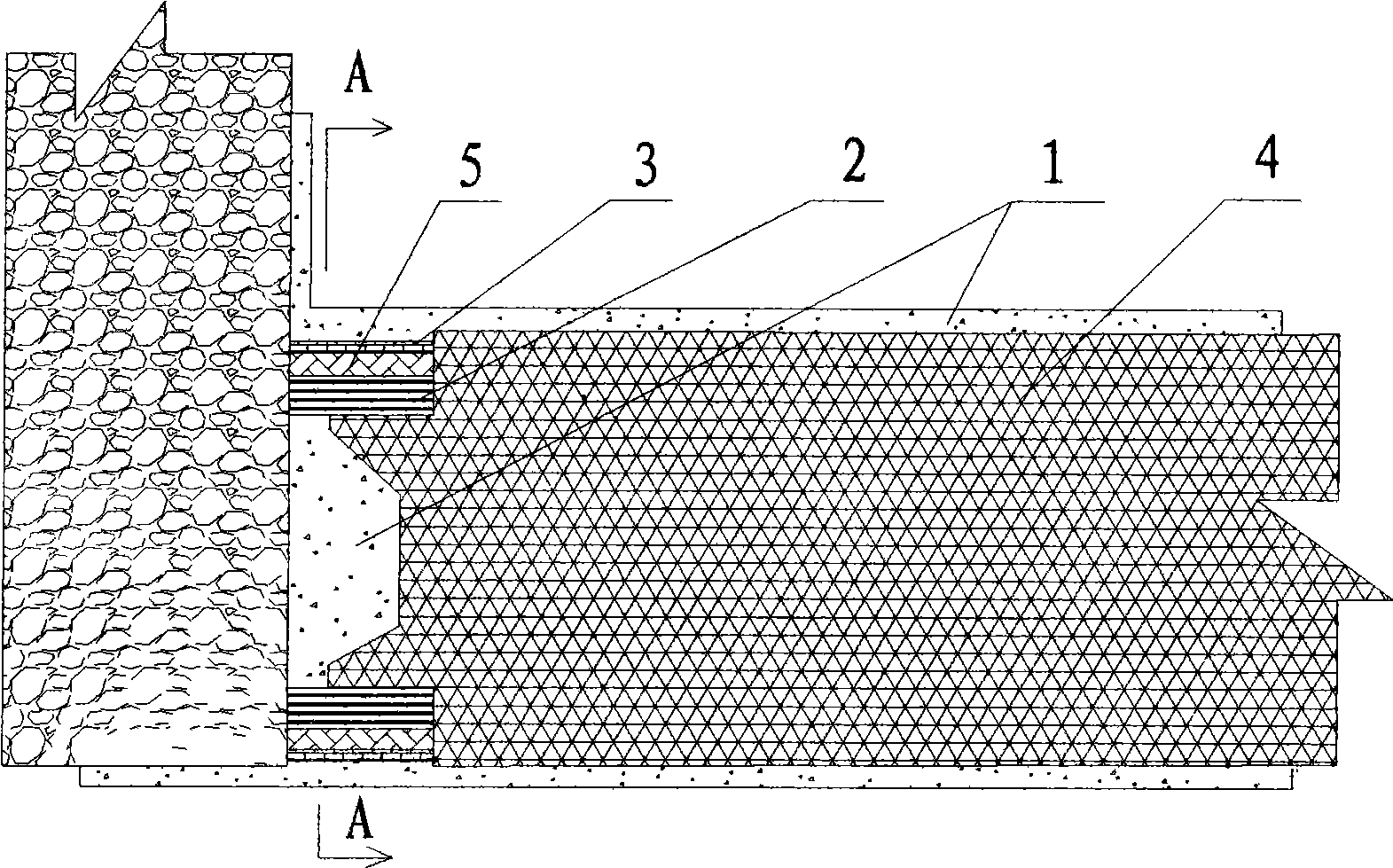

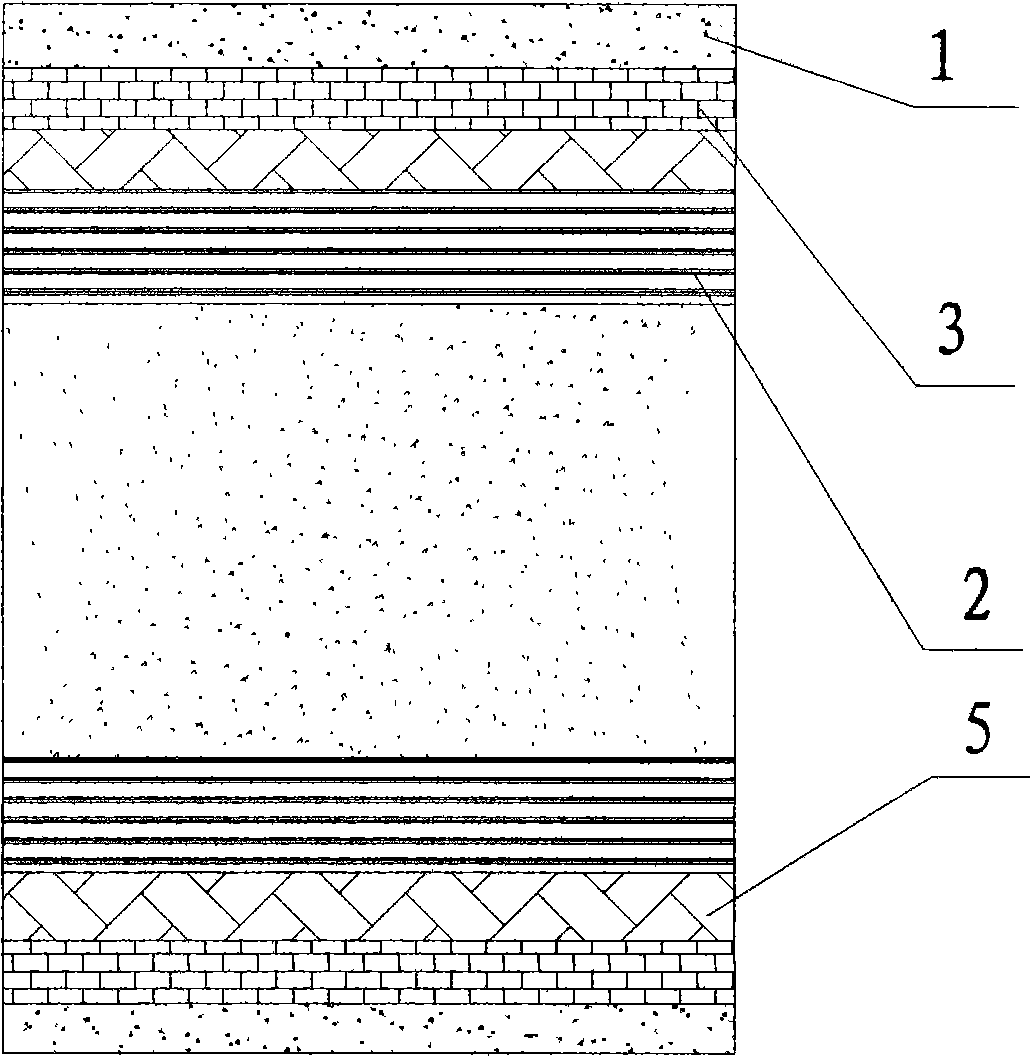

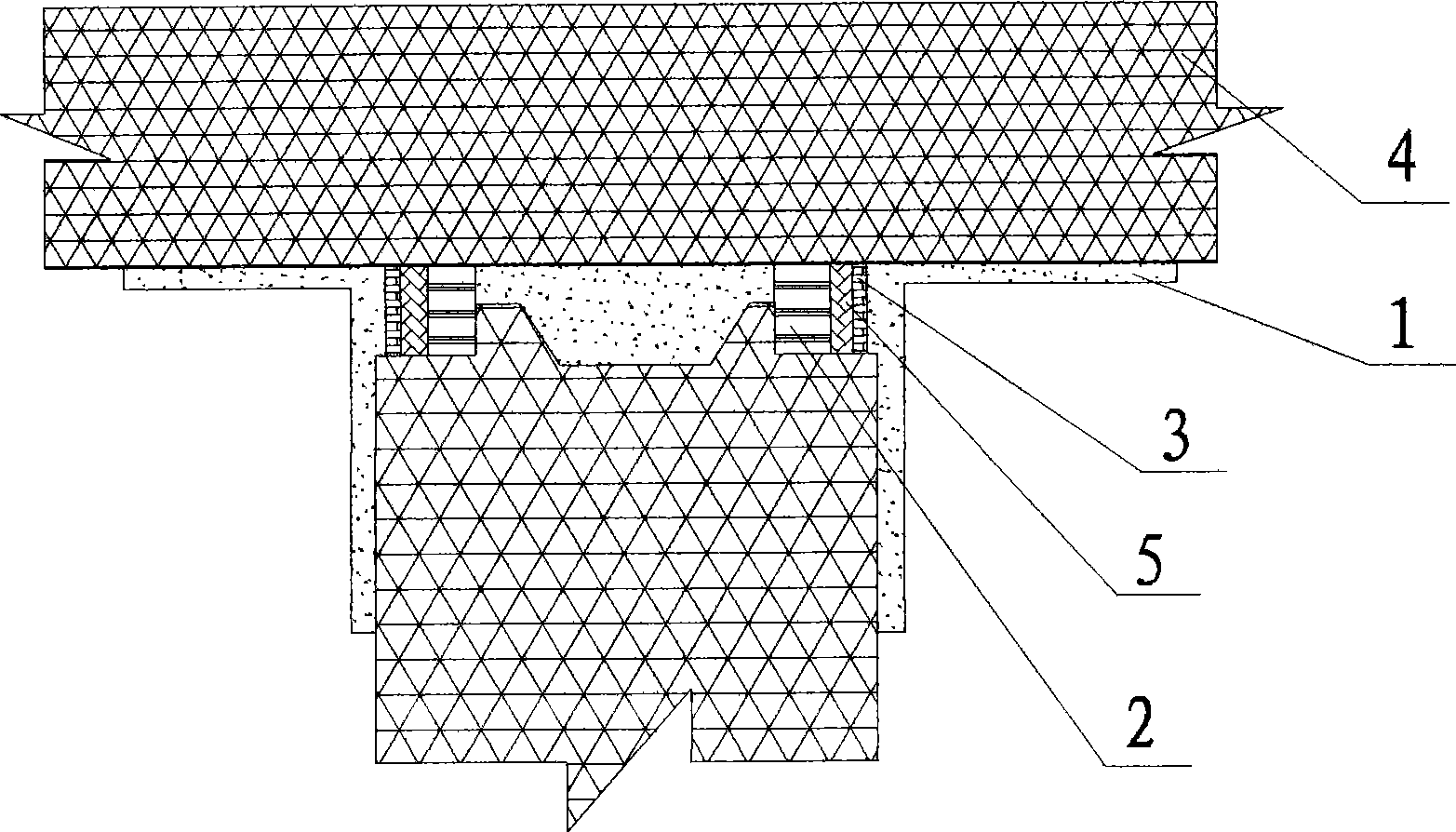

[0017] Referring to the attached drawing, the anti-cracking construction method of light-weight slats. In this construction method, polymer cement mortar 1 is used as the joint material, and waterproof slurry 2 is used for secondary scraping at the joints of slats 4, and anti-cracking is pasted Fiber cloth, the specific steps are as follows:

[0018] A. Apply a layer of 10mm polymer cement mortar 1 on the contact surface of the batten 4 and the batten 4 or the contact surface between the batten 4 and the wall surface;

[0019] B. Assemble the slats 4 by using the lower wedge top plate method, and fill all the joints with polymer cement mortar 1;

[0020] C. Fill the joints in the grooves of the slats with two waterproof grouts 2;

[0021] D. After the waterproof slurry 2 is solidified, first coat a layer of 108 glue 5 on the waterproof slurry 2, then paste the alkali-resistant glass fiber mesh cloth 3 on the 108 glue 5, and finally use the polymer cement mortar 1 to seal the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com