Full-range sand-adding yield increase construction method for oil well

A construction method and oil well technology, applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve problems such as difficult-to-control fractures, high proportion of prefluid, high sand plugging rate, etc., to increase efficiency and save construction Cost, Pollution Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

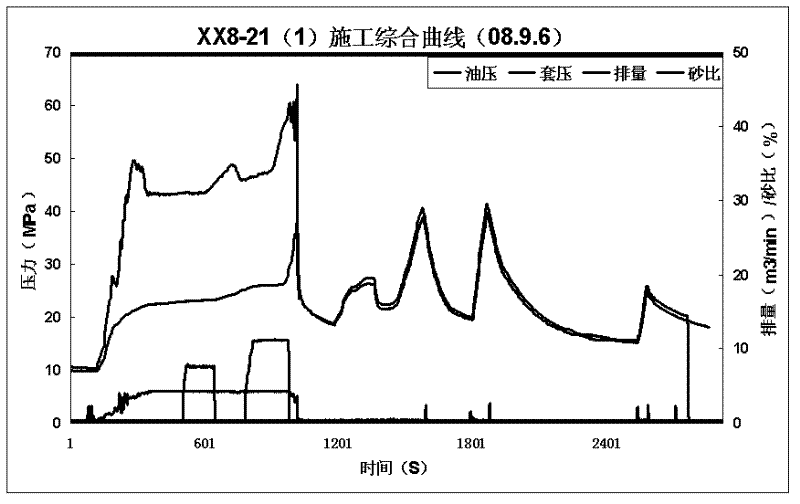

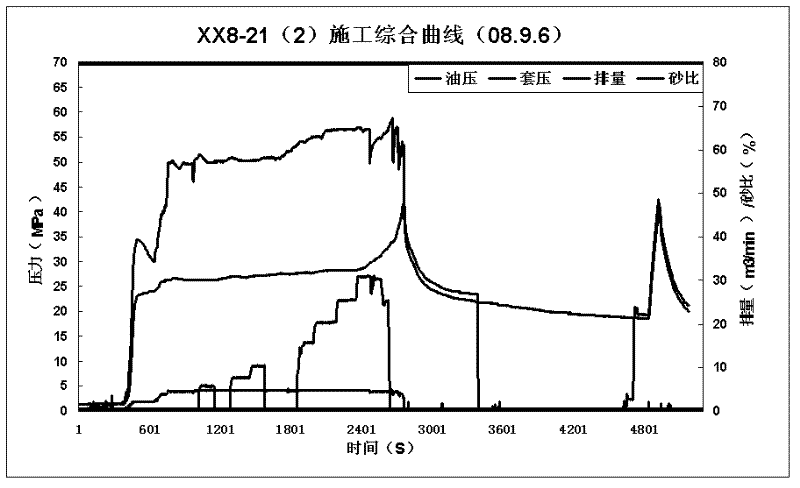

[0024] The construction method of adding sand to increase production in the whole oil well includes the following steps: (1) select volcanic rock vug type or loose sandstone pore type or fracture type reservoir, start the injection pump, 3 The initial displacement speed of / min injects the injection fluid into the oil well through the injection tubing, and gradually increases the displacement to 3-4.5m 3 / min; At the same time, gradually increase the injection pressure to gradually increase the casing pressure by 2-3Mpa; (2) When the injected fluid reaches the volume of one or two injection tubing strings and the injected fluid enters the formation, start adding sand to the injected fluid And gradually increase the sand ratio. The sand ratio refers to the percentage of the sand volume in the injection liquid and the injection liquid volume. The sand ratio adjustment range is controlled at 5-10%, and the sand volume is 2-3.5m 3 ; At the same time, gradually increase the injecti...

Embodiment 2

[0026] For volcanic rock vug reservoirs, the construction method of adding sand to increase production in the whole process of the oil well is as follows: ①Start the injection pump, 3 Inject the injection fluid into the oil well at the initial displacement speed of / min, and gradually increase the displacement to 3-4.5m 3 / min, the displacement lifting speed is 2-2.5m 3 / 5min; at the same time, gradually increase the injection pressure to gradually increase the casing pressure by 2-3Mpa; ②When the injected liquid reaches the volume of two injection strings and the injected liquid enters the formation, start adding sand to the injected liquid, and the initial sand ratio is 5% and gradually increase the sand ratio, the sand ratio adjustment range is controlled at 5-10%, and the sand volume reaches 2-3.5m 3 , to ensure that the length of the artificial fracture extends through the near-wellbore zone; at the same time, gradually increase the injection pressure to gradually increa...

Embodiment 3

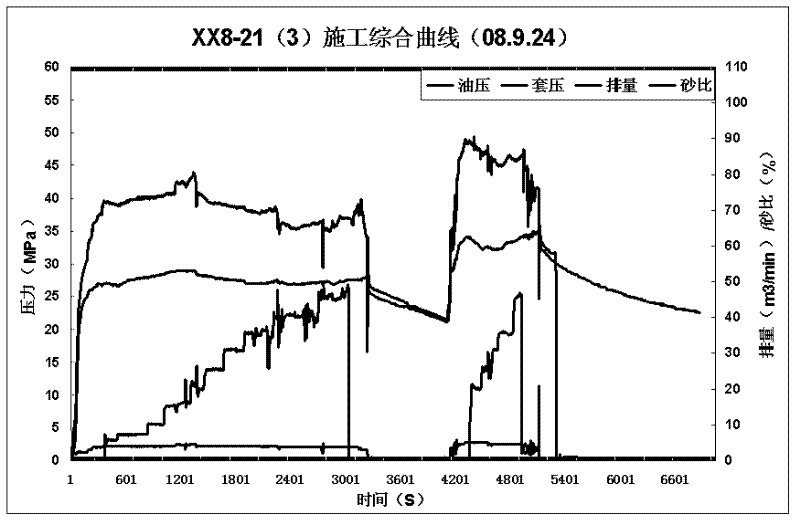

[0030] For volcanic rock vug reservoirs, the construction method of adding sand to increase production in the whole process of the oil well is as follows: ①Start the injection pump, 3 Inject fluid into the oil well at the initial displacement speed of / min, and gradually increase the displacement to 4m 3 / min, the displacement lifting speed is 2.2m 3 / 5min; at the same time, gradually increase the injection pressure to gradually increase the casing pressure by 2.5Mpa; ②When the injected liquid reaches the volume of two injection strings and the injected liquid enters the formation, start adding sand to the injected liquid, and the initial sand ratio is 5 % and gradually increase the sand ratio, the sand ratio adjustment range is controlled at 5-10%, and the sand volume reaches 3m 3 , to ensure that the length of the artificial fracture extends through the near-wellbore zone; at the same time, gradually increase the injection pressure to gradually increase the casing pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com