Method and device for testing low-temperature property of drilling fluid

A low-temperature performance and testing device technology, applied in the direction of measuring devices, chemical instruments and methods, flow characteristics, etc., can solve the problem that the drilling fluid system is difficult to meet the requirements of natural gas hydrate and permafrost drilling, and achieve low cost, large size, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

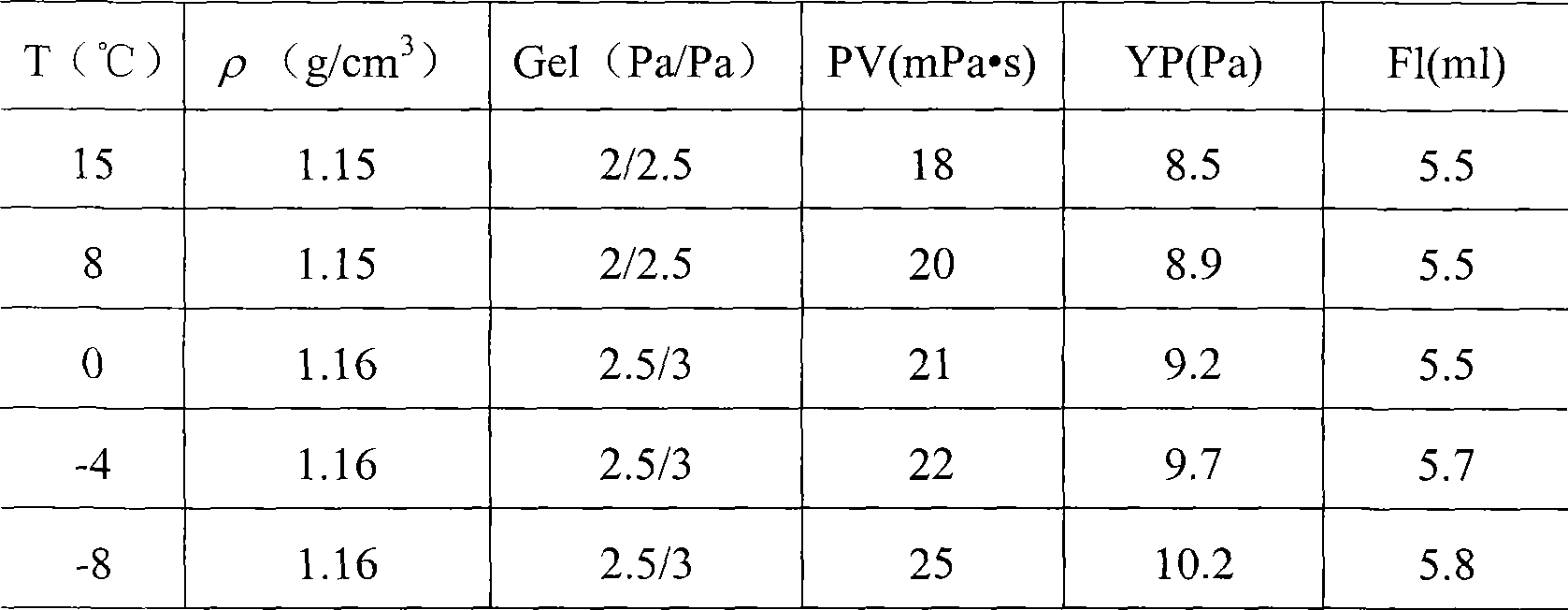

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

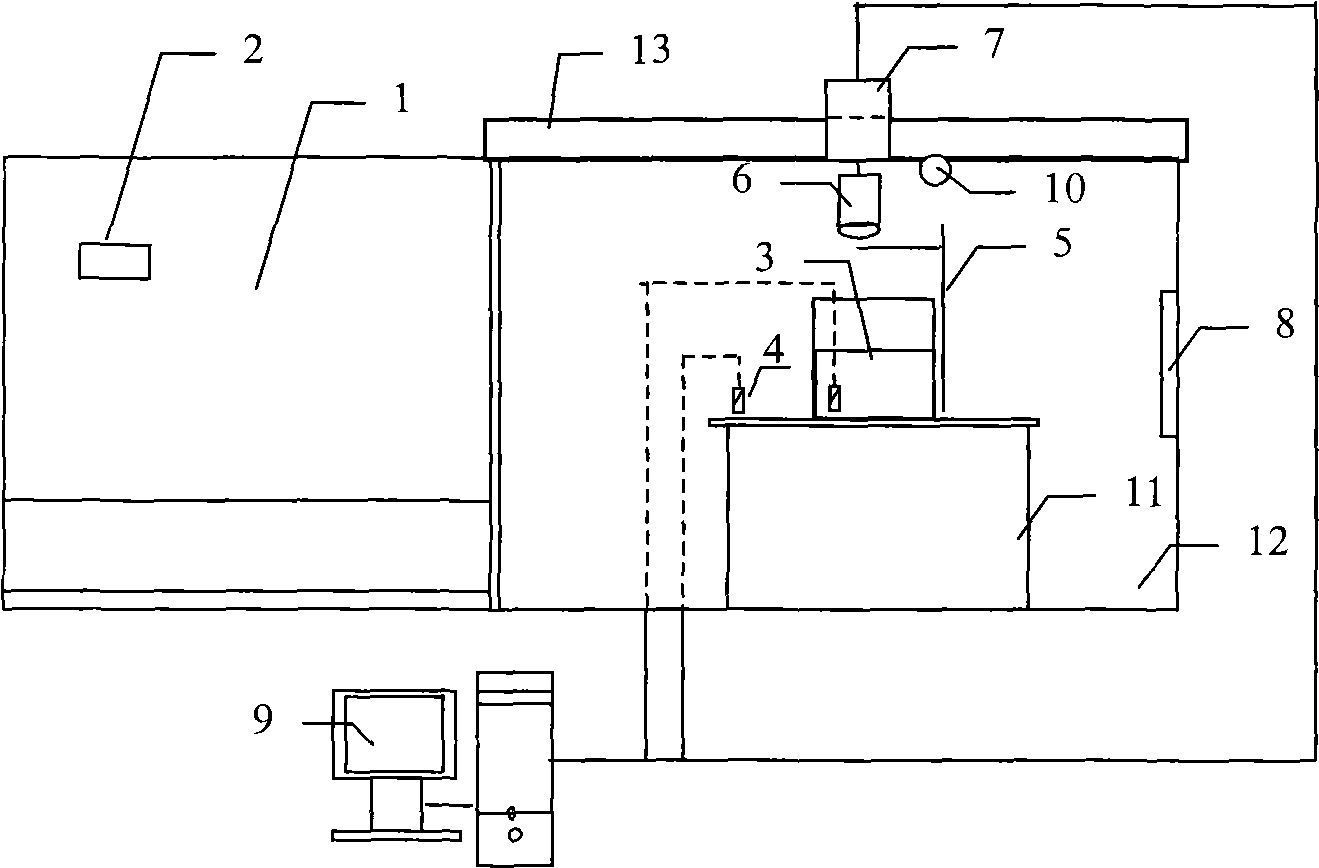

[0017] The device provided by the present invention is a drilling fluid low temperature performance testing device, the structure of which is as follows: figure 1 Shown: It consists of a high and low temperature experimental box 1 with dehumidification and programmable functions, a data acquisition system 9 for collecting and displaying experimental temperature and video images, a camera 6 for obtaining images of scale markings on the test instrument, and a camera located in the experimental box Composed of two temperature sensors 4 in. Wherein: the testing instrument is positioned on the operating platform 11 in the working room 12 of this experiment box; In the drilling fluid 3 on the operating platform, it is used to detect the temperature of the drilling fluid 3; the camera 6 is placed on the top of the test box body, and the camera can adopt a 1.2 million pixel ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com