Silver, gold nano particle distributed silicon dioxide optical thin-film and preparation method thereof

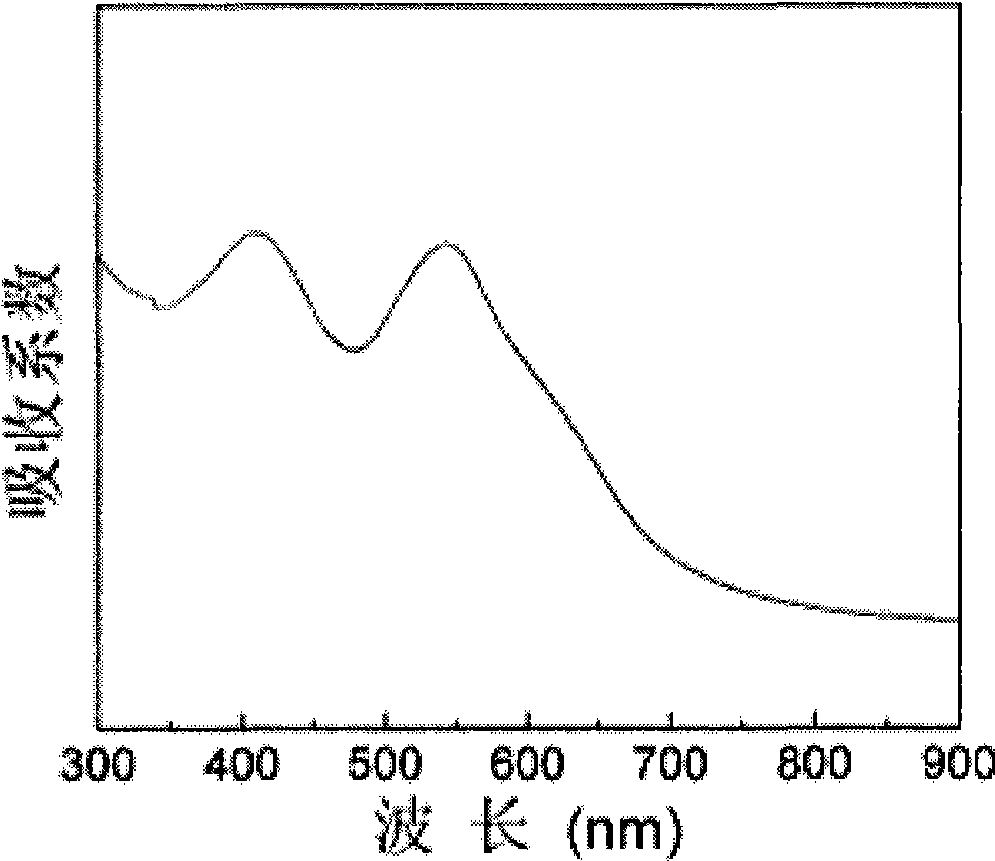

A metal nanoparticle, dispersion technology, applied in the direction of optics, nonlinear optics, instruments, etc., to achieve the effect of excellent nonlinear optical properties and increase the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Dissolve 5ml of tetraethyl orthosilicate in 19.5ml of absolute ethanol, add 2ml of distilled water, then add a few drops of nitric acid, and stir for 1 hour to obtain colorless and transparent SiO 2 parent solution, then add 0.0422g of silver nitrate, and stir again for 1 hour to obtain Ag 0.02 / (SiO 2 ) 0.98 Precursor solution; using the same method, add 0.0977g chloroauric acid to prepare Au 0.02 / (SiO 2 ) 0.98precursor solution. Before the glue is shaken, the substrate is immersed in acetone for ultrasonic cleaning for 5 minutes, then rinsed with distilled water and dried, and then coated on the glass substrate with a glue homogenizer. Coat Ag first 0.02 / (SiO 2 ) 0.98 film, the Ag 0.02 / (SiO 2 ) 0.98 The precursor solution was dripped onto the substrate, and then operated at a speed of 3000 rpm for 10 seconds and then at a speed of 3000 rpm for 30 seconds. After homogenizing, the sample was thermally decomposed at 180°C for 5 minutes, and after cooling, ...

Embodiment 2

[0015] Dissolve 5ml of tetraethyl orthosilicate in 19.5ml of absolute ethanol, add 2ml of distilled water, then add a few drops of nitric acid, and stir for 1 hour to obtain colorless and transparent SiO 2 parent solution, then add 0.9499g of silver nitrate, and stir again for 1 hour to obtain Ag 0.2 / (SiO 2 ) 0.8 Precursor solution; using the same method, add 0.4848g chloroauric acid to prepare Au 0.1 / (SiO 2 ) 0.9 precursor solution. Before spinning the glue, soak the substrate in acetone for ultrasonic cleaning for 5 minutes, then rinse it with distilled water and dry it, and then apply a film on the substrate by the glue leveling method. Coated Au first 0.1 / (SiO 2 ) 0.9 film, the Au 0.1 / (SiO 2 ) 0.9 The precursor solution was dripped onto the substrate, and then operated at a speed of 3000 rpm for 10 seconds and then at a speed of 3000 rpm for 30 seconds. After homogenizing, the sample was thermally decomposed at 180°C for 5 minutes, and after the sample was ...

Embodiment 3

[0017] Dissolve 5ml of tetraethyl orthosilicate in 19.5ml of absolute ethanol, add 5ml of distilled water, then add a few drops of nitric acid, and stir for 1 hour to obtain colorless and transparent SiO 2 parent solution, then add 3.7997g of silver nitrate, and stir again for 1 hour to obtain Ag 0.9 / (SiO 2 ) 0.1 Precursor solution; using the same method, add 5.583g chloroauric acid to prepare Au 0.6 / (SiO 2 ) 0.4 precursor solution. Before the glue is shaken, the substrate is immersed in acetone for ultrasonic cleaning for 5 minutes, then rinsed with distilled water and dried, and then coated on the glass substrate with a glue leveler. Coat Ag first 0.9 / (SiO 2 ) 0.1 film, the Ag 0.9 / (SiO 2 ) 0.1 The precursor solution was dripped onto the substrate, and then operated at a speed of 3000 rpm for 10 seconds and then at a speed of 3000 rpm for 30 seconds. After homogenizing, thermally decompose the sample at 180°C for 5 minutes. After the sample is cooled, apply an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com