Dispersed cobaltosic oxide optical film of silver and gold nano particles and preparation method

A metal nanoparticle, dispersion technology, applied in the direction of optics, nonlinear optics, instruments, etc., to achieve the effect of excellent nonlinear optical properties and increase the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

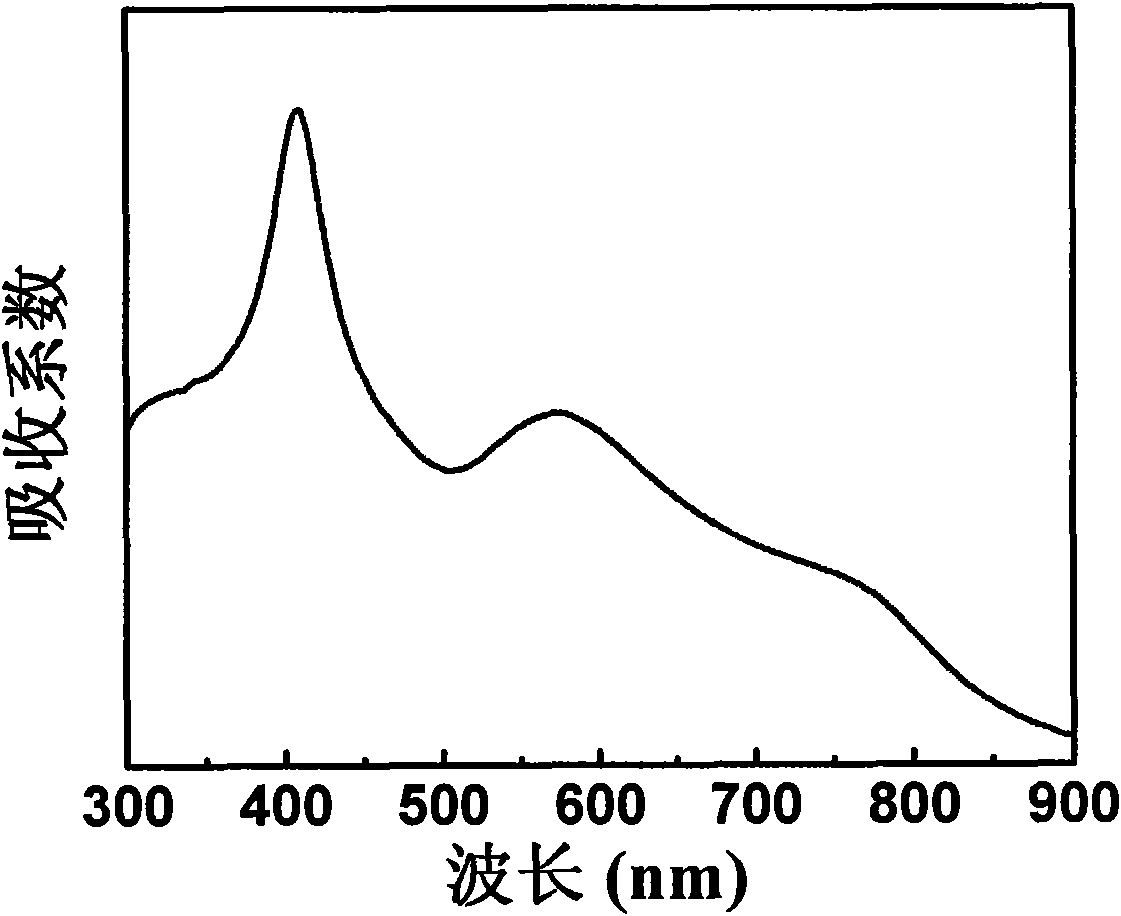

Image

Examples

Embodiment 1

[0007] Weigh 0.8731g of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 0.1699g of silver nitrate (AgNO 3 ) and 0.4188g of chloroauric acid (HAuCl 4 4H 2 (2), join respectively in the 10ml ethylene glycol monomethyl ether solvent, stir 3 hours on the magnetic stirrer, aging 6 hours, obtain the Co parent solution that concentration is 0.3mol / L, the Ag parent solution of 0.1mol / L and 0.1mol / L Au parent solution; then measure 9.8ml of Co parent solution and 0.2ml of Ag parent solution, mix the two solutions, stir on a magnetic stirrer for 5 hours, and age for 8 hours to obtain Ag 0.02 / (Co 3 o 4 ) 0.98 precursor solution. In the same way, measure 9.8ml of Co parent solution and 0.2ml of Au parent solution to prepare Au 0.02 / (Co 3 o 4 ) 0.98 precursor solution. Before gluing, the substrate was ultrasonically cleaned in distilled water, ethanol, and acetone, and then put into a drying oven to dry, and then coated with a layer of prepared Ag 0.02 / (Co 3 o 4 ) 0.98 The precur...

Embodiment 2

[0009] Weigh 0.8731g of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 0.1699g of silver nitrate (AgNO 3 ) and 0.4188g of chloroauric acid (HAuCl 4 4H 2 (2), join respectively in the 10ml ethylene glycol monomethyl ether solvent, stir 3 hours on the magnetic stirrer, aging 6 hours, obtain the Co parent solution that concentration is 0.3mol / L, the Ag parent solution of 0.1mol / L and Au matrix solution of 0.1mol / L; then measure 6ml of Co matrix solution and 4ml of Ag matrix solution, mix the two solutions, stir on a magnetic stirrer for 5 hours, and age for 8 hours to obtain Ag 0.4 / (Co 3 o 4 ) 0.6 precursor solution. In the same way, measure 6ml of Co parent solution and 4ml of Au parent solution to prepare Au 0.4 / (Co 3 o 4 ) 0.6 precursor solution. Before gluing, the substrate was ultrasonically cleaned in distilled water, ethanol, and acetone, and then put into a drying oven to dry, and then coated with a layer of prepared Ag 0.4 / (Co 3 o 4 ) 0.6 The precursor solutio...

Embodiment 3

[0011] Weigh 0.8731g of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 0.1699g of silver nitrate (AgNO 3 ) and 0.4188g of chloroauric acid (HAuCl 4 4H 2 (2), join respectively in the 10ml ethylene glycol monomethyl ether solvent, stir 3 hours on the magnetic stirrer, aging 6 hours, obtain the Co parent solution that concentration is 0.3mol / L, the Ag parent solution of 0.1mol / L and 0.1mol / L Au parent solution; then measure 1ml of Co parent solution and 9ml of Ag parent solution, mix the two solutions, stir on a magnetic stirrer for 5 hours, and age for 8 hours to obtain Ag 0.9 / (Co 3 o 4 ) 0.1 precursor solution. In the same way, measure 4ml of Co parent solution and 6ml of Au parent solution to prepare Au 0.6 / (Co 3 o 4 ) 0.4 precursor solution. Before gluing, the substrate was ultrasonically cleaned in distilled water, ethanol, and acetone, and then put into a drying oven to dry, and then coated with a layer of prepared Ag 0.9 / (Co 3 o 4 ) 0.1 The precursor solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com