A kind of preparation method of graphene and tin oxide hollow sphere composite nanomaterial

A technology of composite nanomaterials and hollow spheres, applied in the direction of graphene, tin oxide, nano-carbon, etc., can solve the problems of cumbersome preparation process and weak third-order nonlinear optical response, and achieve simple steps, strong nonlinear optical properties, The effect of promoting crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

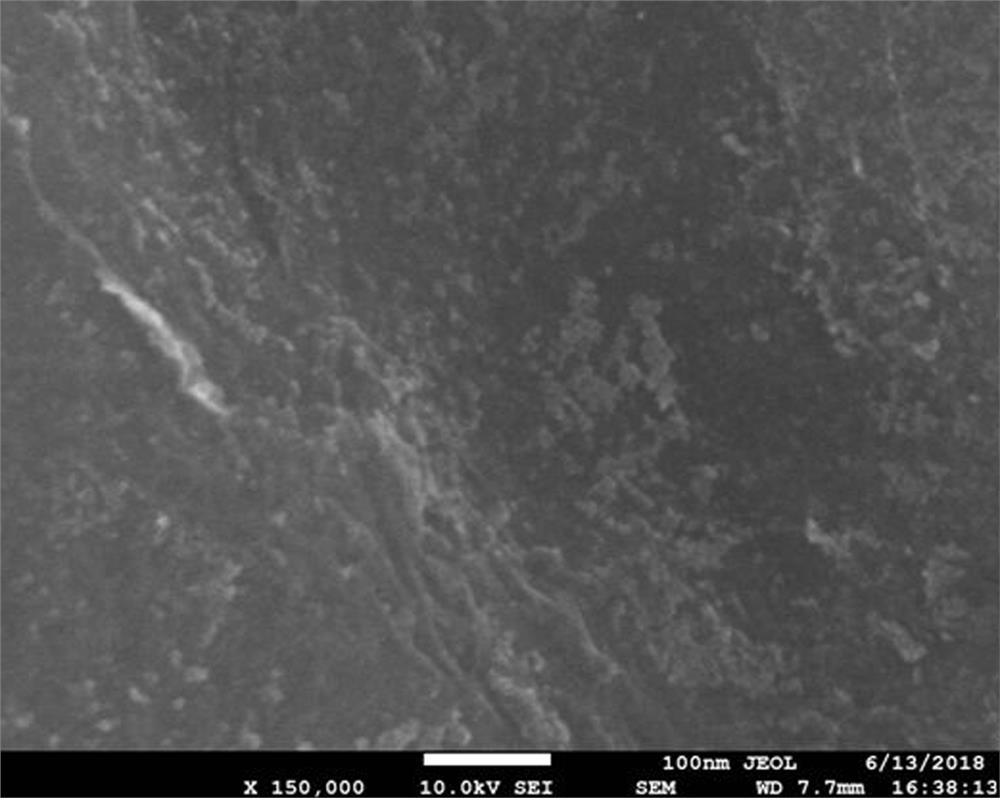

Embodiment 1

[0029] Take 0.182gK 2 SnO 3 ·3H 2 Put O into a beaker, add 35 mL of deionized water, and stir magnetically for 20 minutes to obtain an aqueous solution of potassium sulfate; put 0.24 g of urea into another beaker, add 5 mL of ethanol, and stir magnetically for 20 minutes to obtain a urea solution. Add the potassium sulfate aqueous solution to the urea solution, and ultrasonically treat it for 30 minutes to form a mixed solution;

[0030] Put 0.124mg of graphene oxide in a beaker, add 10mL of deionized water, stir magnetically for 20min, then add the mixed solution prepared above, and put it on a magnetic stirrer and stir continuously for 20min to obtain an intermediate solution;

[0031] Transfer the intermediate solution to a high-pressure stainless steel reactor lined with polytetrafluoroethylene, and put it in a vacuum oven at 190°C for 15 hours;

[0032] After the reaction, put the autoclave into ice water to quench quickly, wash the cooled reaction solution with deioni...

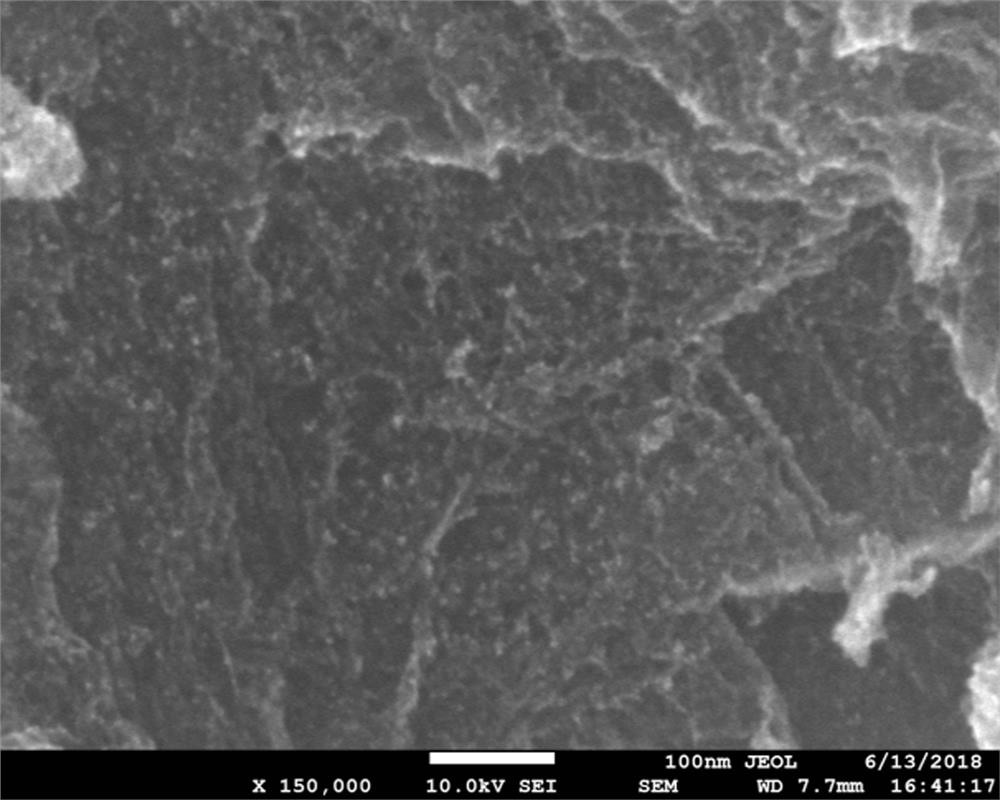

Embodiment 2

[0035] Take 0.182gK 2 SnO 3 ·3H 2 Put O into a beaker, add 30 mL of deionized water, and stir magnetically for 20 minutes to obtain an aqueous solution of potassium sulfate; put 0.24 g of urea into another beaker, add 10 mL of ethanol, and stir magnetically for 20 minutes to obtain a urea solution. Add the potassium sulfate aqueous solution to the urea solution, and ultrasonically treat it for 30 minutes to form a mixed solution;

[0036] Put 0.124mg of graphene oxide in a beaker, add 10mL of deionized water, stir magnetically for 20min, then add the mixed solution prepared above, and put it on a magnetic stirrer and stir continuously for 20min to obtain an intermediate solution;

[0037] Transfer the intermediate solution to a high-pressure stainless steel reactor lined with polytetrafluoroethylene, and put it in a vacuum oven at 190°C for 15 hours;

[0038] After the reaction, put the autoclave into ice water to quench quickly, wash the cooled reaction solution with deion...

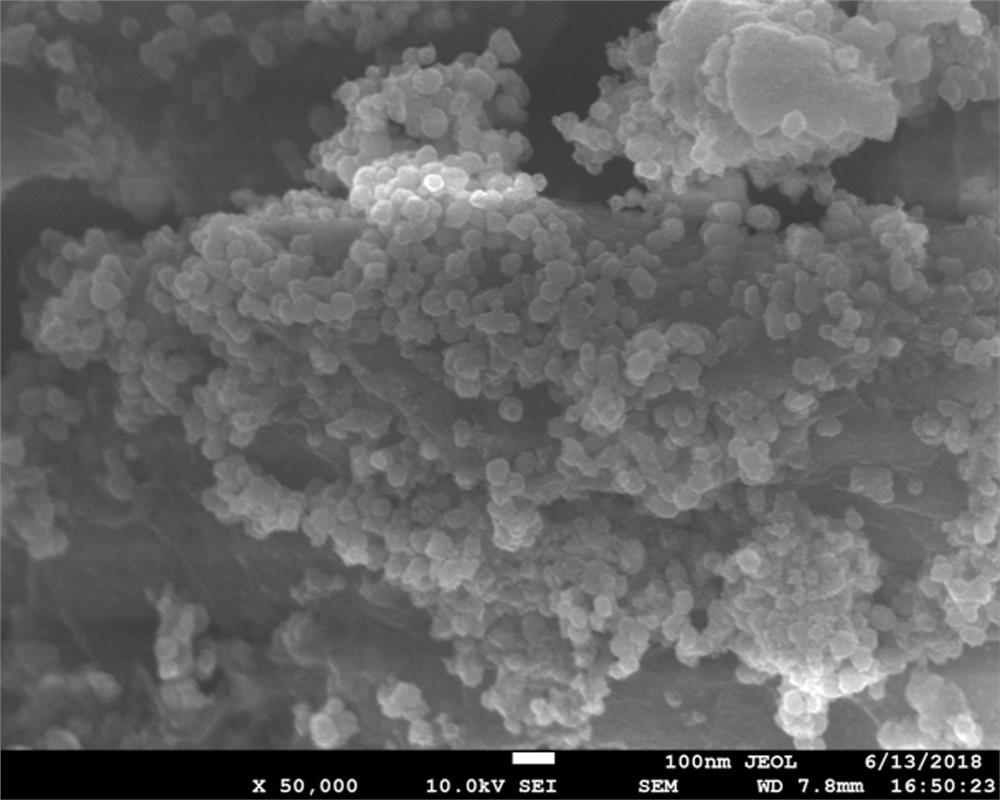

Embodiment 3

[0041] Take 0.182gK 2 SnO 3·3H 2 Put O into a beaker, add 25 mL of deionized water, and stir magnetically for 20 minutes to obtain an aqueous solution of potassium sulfate; put 0.24 g of urea into another beaker, add 15 mL of ethanol, and stir magnetically for 20 minutes to obtain a urea solution. Add the potassium sulfate aqueous solution to the urea solution, and ultrasonically treat it for 30 minutes to form a mixed solution;

[0042] Put 0.124mg of graphene oxide in a beaker, add 10mL of deionized water, stir magnetically for 20min, then add the mixed solution prepared above, and put it on a magnetic stirrer and stir continuously for 20min to obtain an intermediate solution;

[0043] Transfer the intermediate solution to a high-pressure stainless steel reactor lined with polytetrafluoroethylene, and put it in a vacuum oven at 190°C for 15 hours;

[0044] After the reaction, put the autoclave into ice water to quench quickly, wash the cooled reaction solution with deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com