Method of micronization

A powder and protein technology, applied in powder delivery, pharmaceutical formulations, peptide/protein components, etc., can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

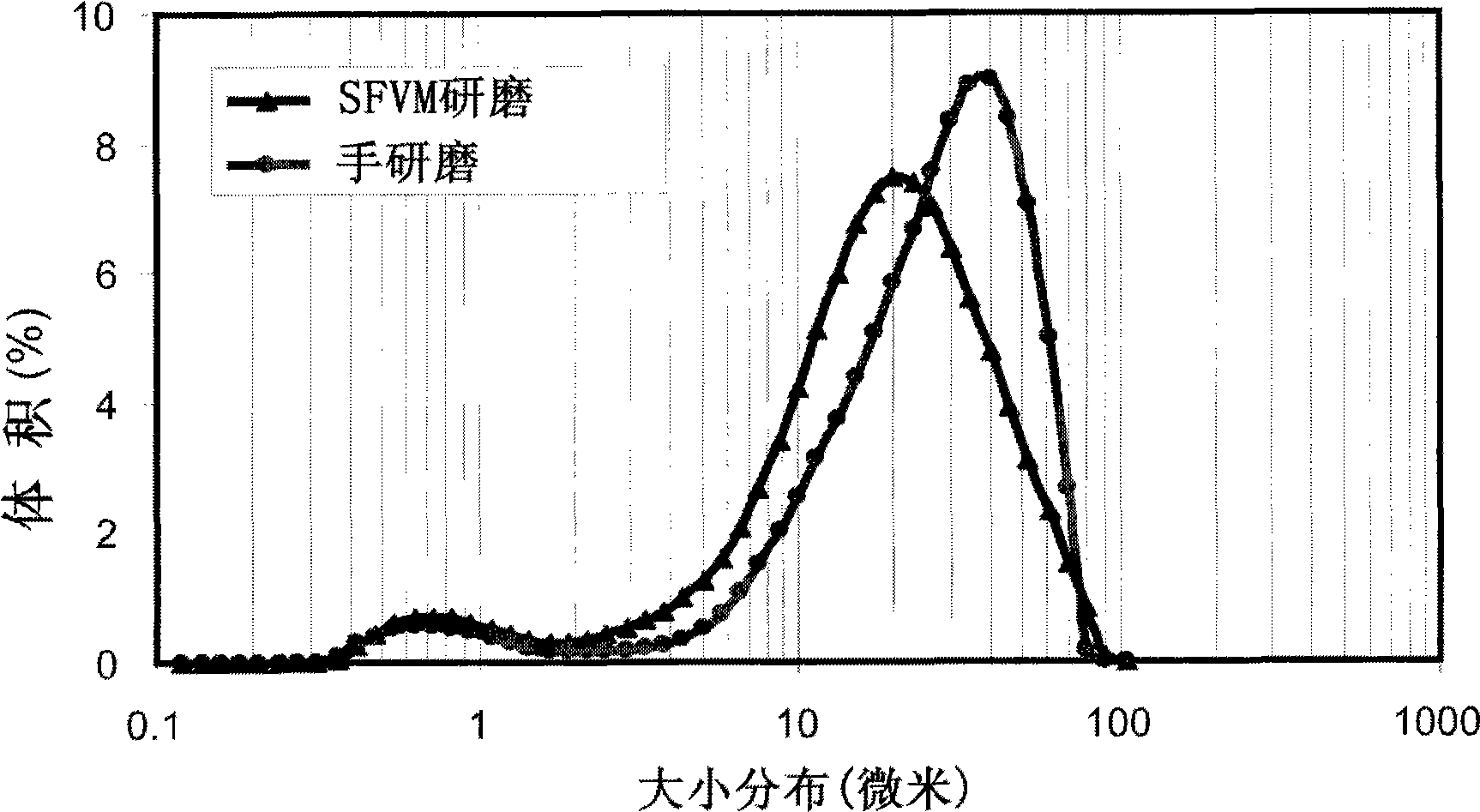

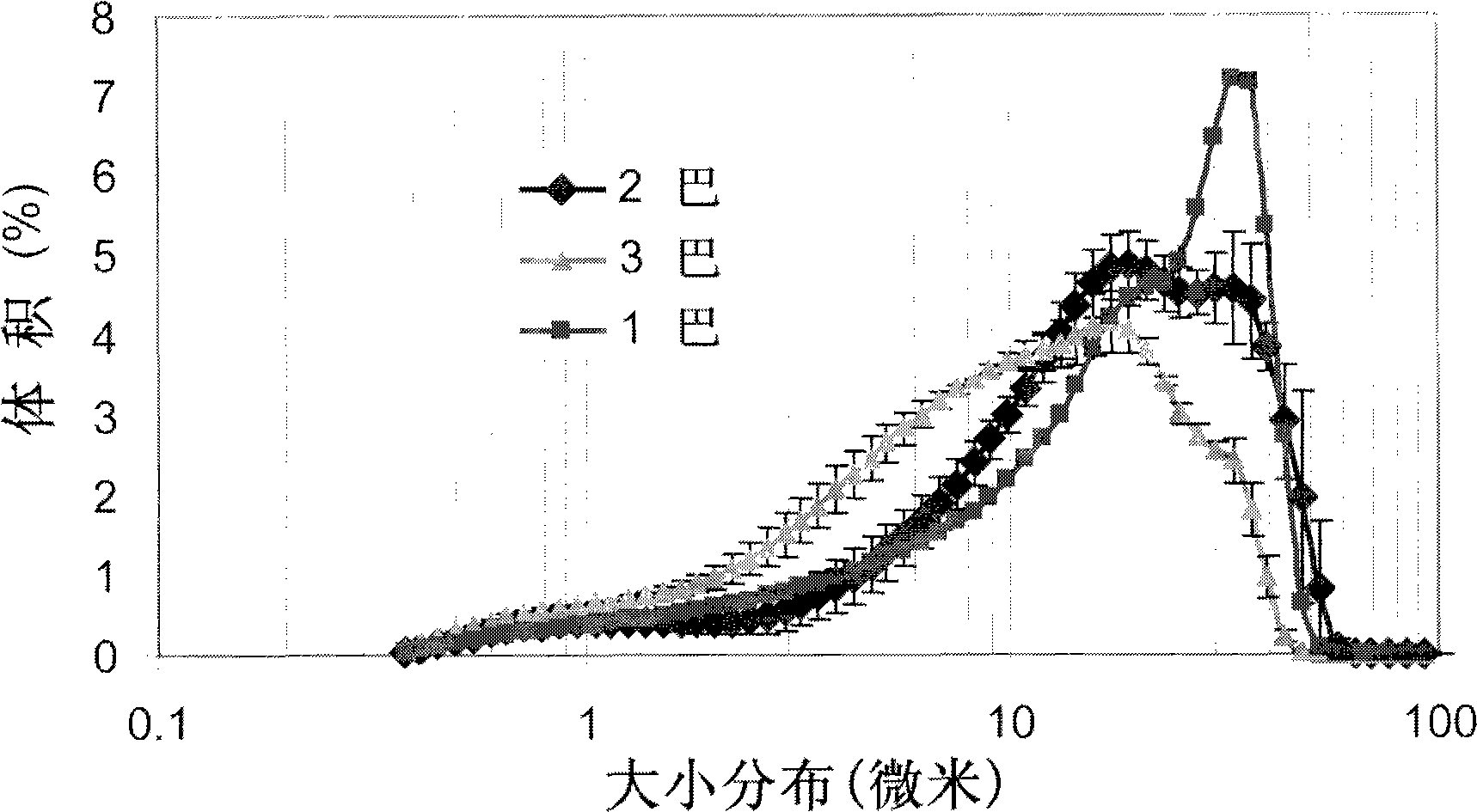

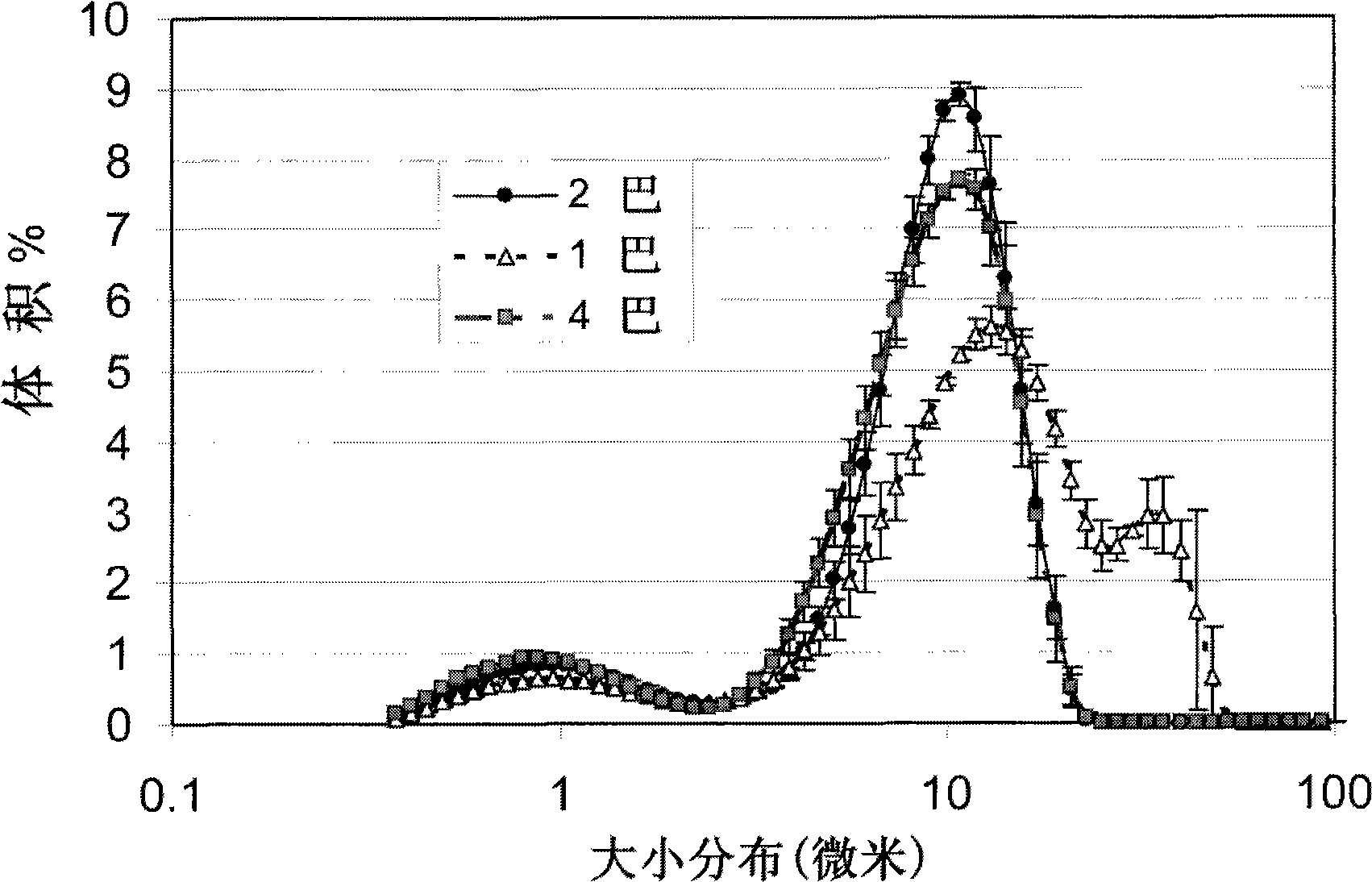

Image

Examples

Embodiment Construction

[0034] Exemplary embodiments of the present invention will be described with respect to SFVM produced by Super Fine Ltd. of Yokneam, Israel. However, it should be understood that other types of grinding machines may be used in accordance with the invention to practice the invention.

[0035] I. Materials

[0036] Biological product

[0037] All batches of human fibrinogen 2 and thrombin biologics were lyophilized at PFI, Tel Hashomer, Israel. Human fibrinogen 2 (sometimes also referred to as BAC2) is concentrated, virus-inactivated human plasma cryoprecipitate (cryoprecipitate is typically prepared as described in EP 534,178) composed primarily of fibrinogen ( approximately 85%) and is plasminogen-depleted (removal of plasminogen is typically performed as described in EP 1,390,485) and no antifibrinolytic agents are added. Biologics arrive as freeze-dried blocks in double-wrapped aluminum foil bags and thick polyethylene bags in a plastic dish. The double-wrapped dishes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com