System implementing low-reductant engine operation mode

一种还原剂、控制系统的技术,应用在发动机元件、燃烧发动机、发动机控制等方向,能够解决没有提供充足供应尿素等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

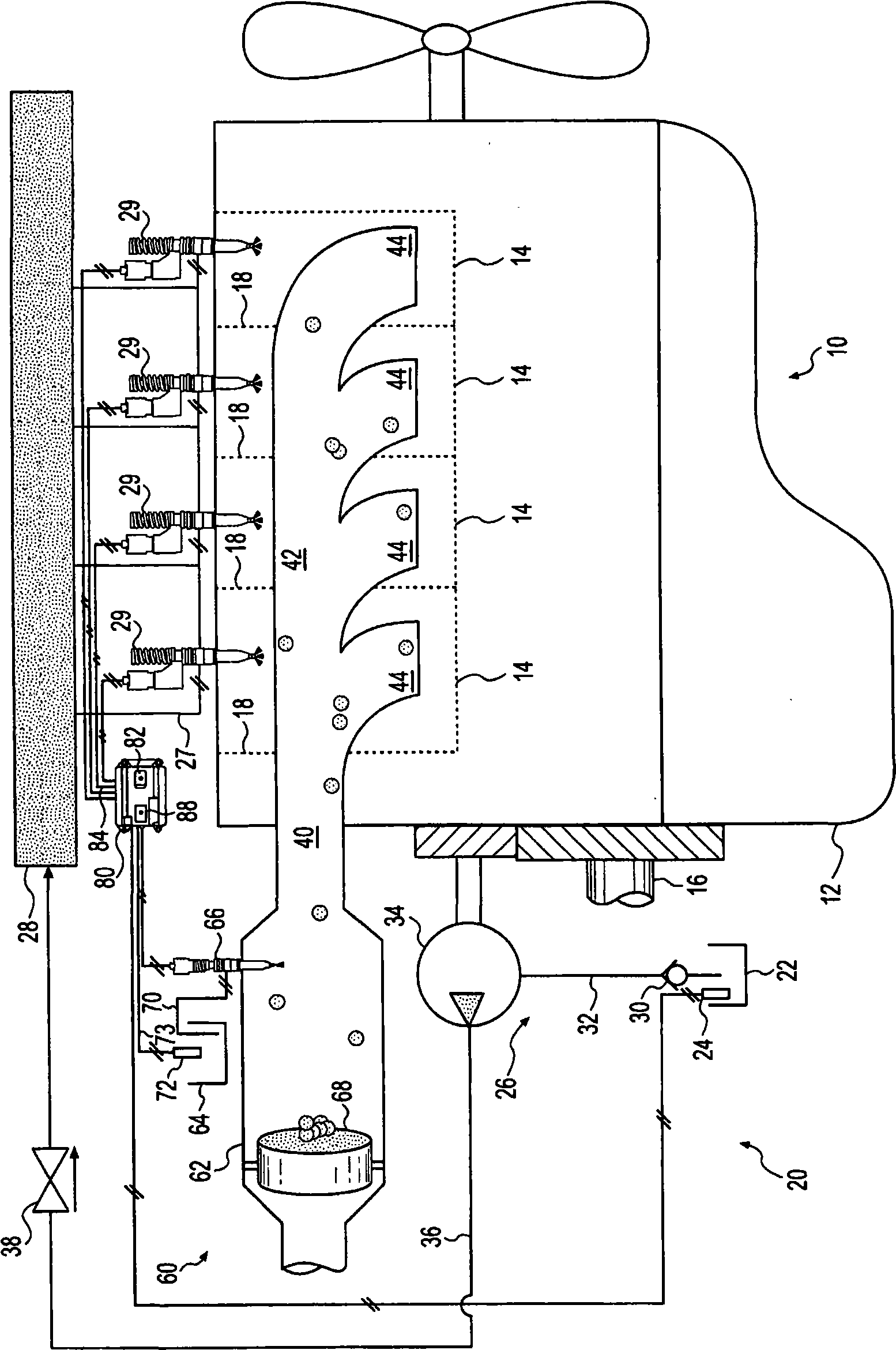

[0014] figure 1 The power unit 10 is shown having a fuel system 20 , an exhaust system 40 and an aftertreatment system 60 . For the present invention, a four-stroke diesel engine is taken as an example to describe and illustrate the power unit 10 . However, those skilled in the art will appreciate that the power unit 10 may be any other type of internal combustion engine, such as a gasoline engine, a gas fuel powered engine or a turbine engine. The power unit 10 may include an engine block 12 at least partially defining a plurality of combustion chambers 14 . In the illustrated embodiment, the power unit 10 has four combustion chambers 14 . However, it is contemplated that the power unit 10 may include a greater or lesser number of combustion chambers 14, and that the combustion chambers 14 may be arranged in an "in-line" configuration, a "V" configuration, or any other suitable configuration.

[0015] same as figure 1 As shown, the power unit 10 may include a crankshaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com