Rush stubble late rice waste grass covering ecological direct sowing method

A technology of rush and late rice, applied in the field of agriculture, can solve problems such as increased labor costs, impact on the ecological environment, and increased labor, and achieve the effect of not affecting the sowing time, improving physical and chemical properties, and increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

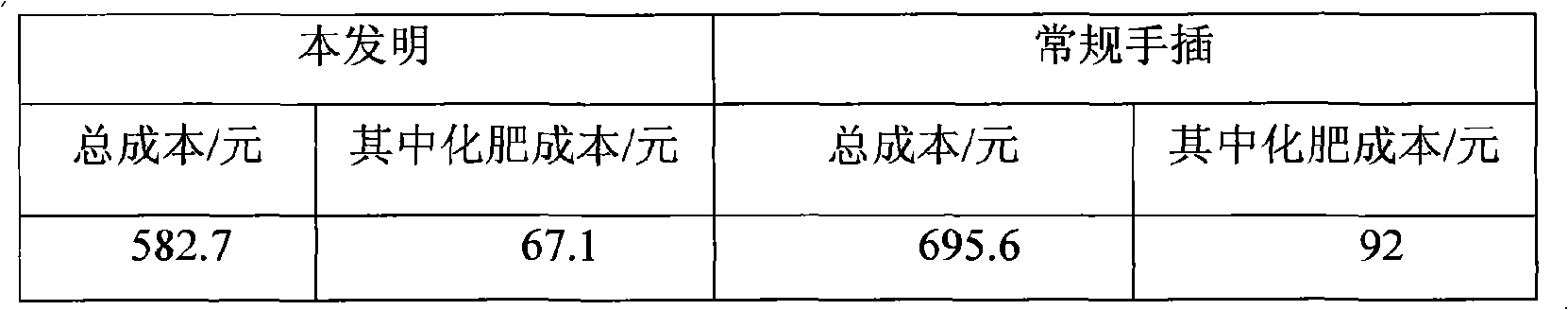

Examples

Embodiment 1

[0031] A kind of rush stubble late rice waste grass covering ecological direct seeding method, it comprises the following steps:

[0032] (1), preparation before sowing:

[0033] ①, rush field preparation

[0034] a. For weeding in the rush field, use herbicides such as Sushou, Guoer, and procaojing for weeding. Do not use chlorsulfuron herbicide, otherwise the residual chlorsulfuron in the soil will affect the growth of inter-sowed late rice seedlings. b. Drainage and irrigation in the rush field When the rush field is placed in the field, dig the surrounding ditches and field operation ditches, and dredge and clean the surrounding ditches and operation ditches before the rush nets are hung. 7 to 10 days before rush harvest, clear the weeds on the fields and dig deep ditches;

[0035] ②, seed preparation

[0036] a. Variety selection, choose a variety with compact plant type, strong stem, medium tillering ability, high fertilizer resistance, more green leaves in the later ...

Embodiment 2

[0051] (1), preparation before sowing:

[0052] ①, rush field preparation

[0053]a. For weeding in the rush field, use herbicides such as Sushou, Guoer, and procaojing for weeding. Do not use chlorsulfuron herbicide, otherwise the residual chlorsulfuron in the soil will affect the growth of inter-sowed late rice seedlings. b. Drainage and irrigation in the rush field When the rush field is placed in the field, dig the surrounding ditches and field operation ditches, and dredge and clean the surrounding ditches and operation ditches before the rush nets are hung. 7 to 10 days before rush harvest, clear the weeds on the fields and dig deep ditches;

[0054] ②, seed preparation

[0055] a. Variety selection, choose a variety with compact plant type, strong stem, medium tillering ability, high fertilizer resistance, many green leaves in the later stage and good color change, choose the conventional variety Yongyou 8, b, seed treatment, first of all sun Seeds, then use 2ml of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com