Gluewater-defoaming device

A technology for glue and foam removal barrels, which is applied in the direction of foam dispersion/prevention, chemical instruments and methods, liquid degassing, etc. It can solve the problems that the bubbles at the bottom of the barrel are difficult to pump up and cannot meet normal production, and achieve a fast speed of foam removal , increase consumption, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

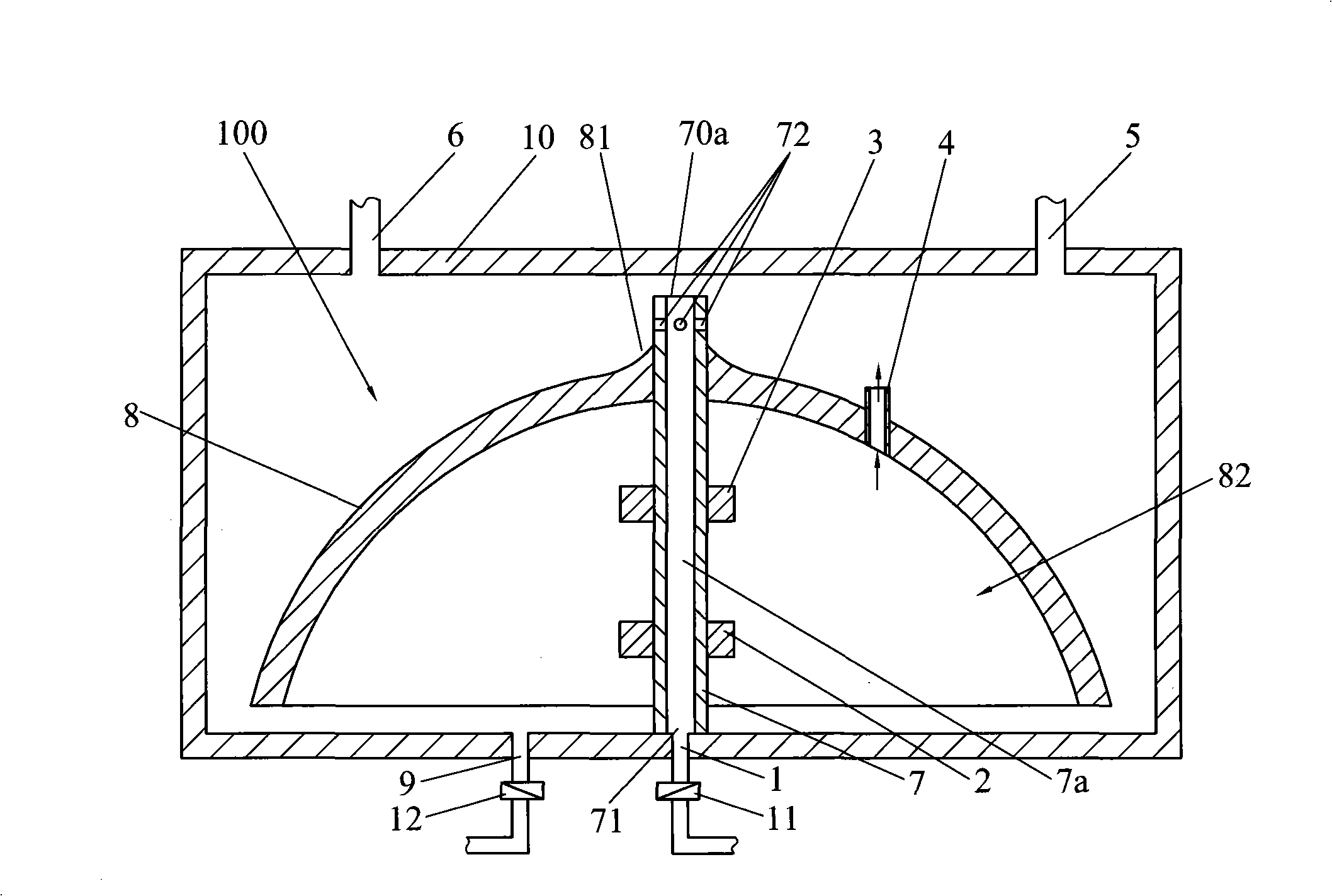

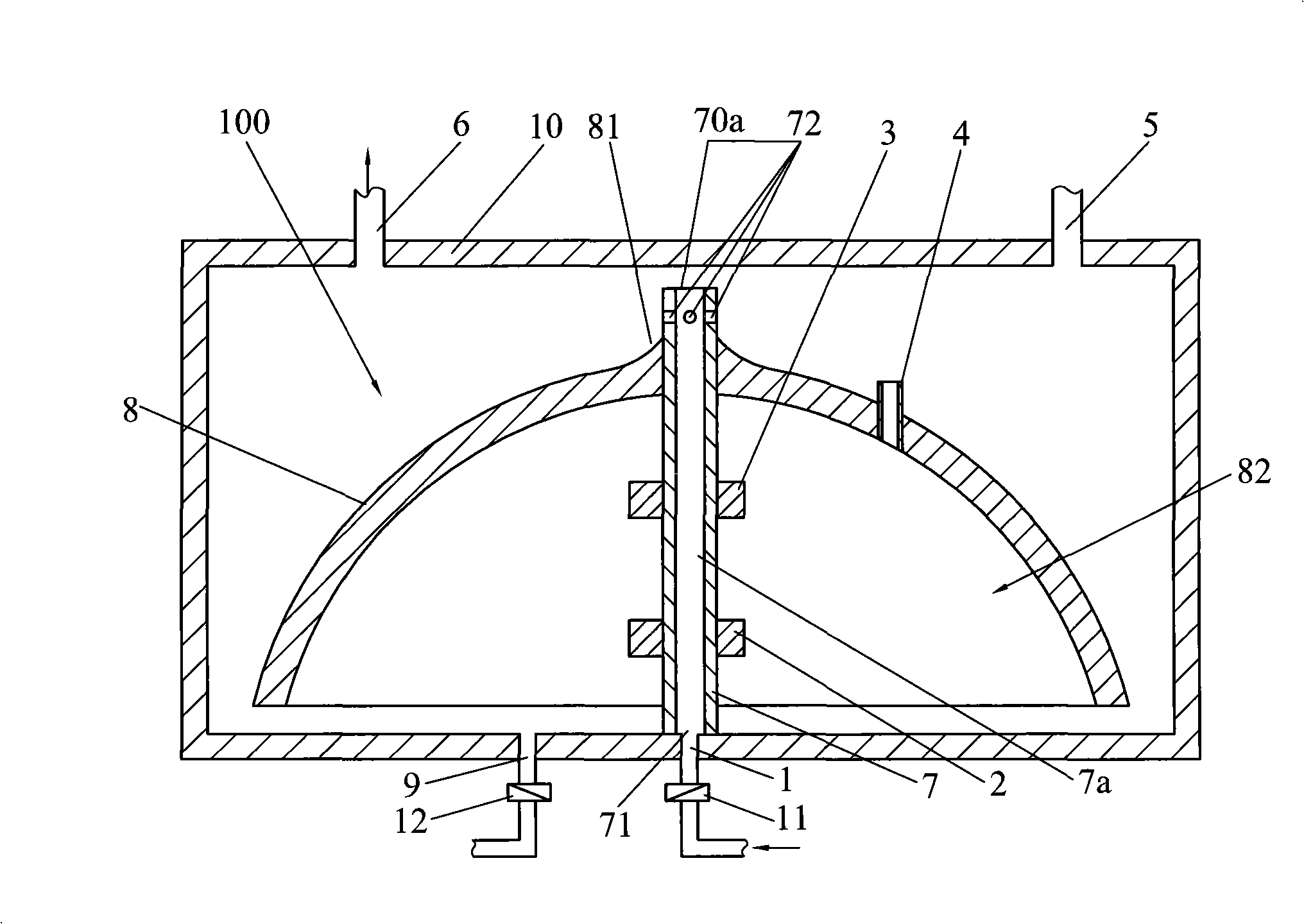

[0021] Such as figure 1 As shown, the glue defoaming device of the present invention includes a glue defoaming bucket 10, and the glue defoaming bucket 10 includes a glue inlet 1, a glue outlet 9, a vacuum port 6 and an air compression port 5, and the vacuum port 6 is connected to the air compression port 5. The vacuum system is connected, and the air compression port 5 is connected with the air compression system; the glue defoaming device of the present invention also includes a defoaming mechanism 100, and the defoaming mechanism 100 includes an internal glue pipe 7 and a hemispherical spherical surface 8, so The inner glue inlet 71 of the inner glue pipe 7 is connected to the glue inlet 1, and the inner glue outlet 72 of the inner glue pipe 7 is located above the vertex 81 of the spherical surface.

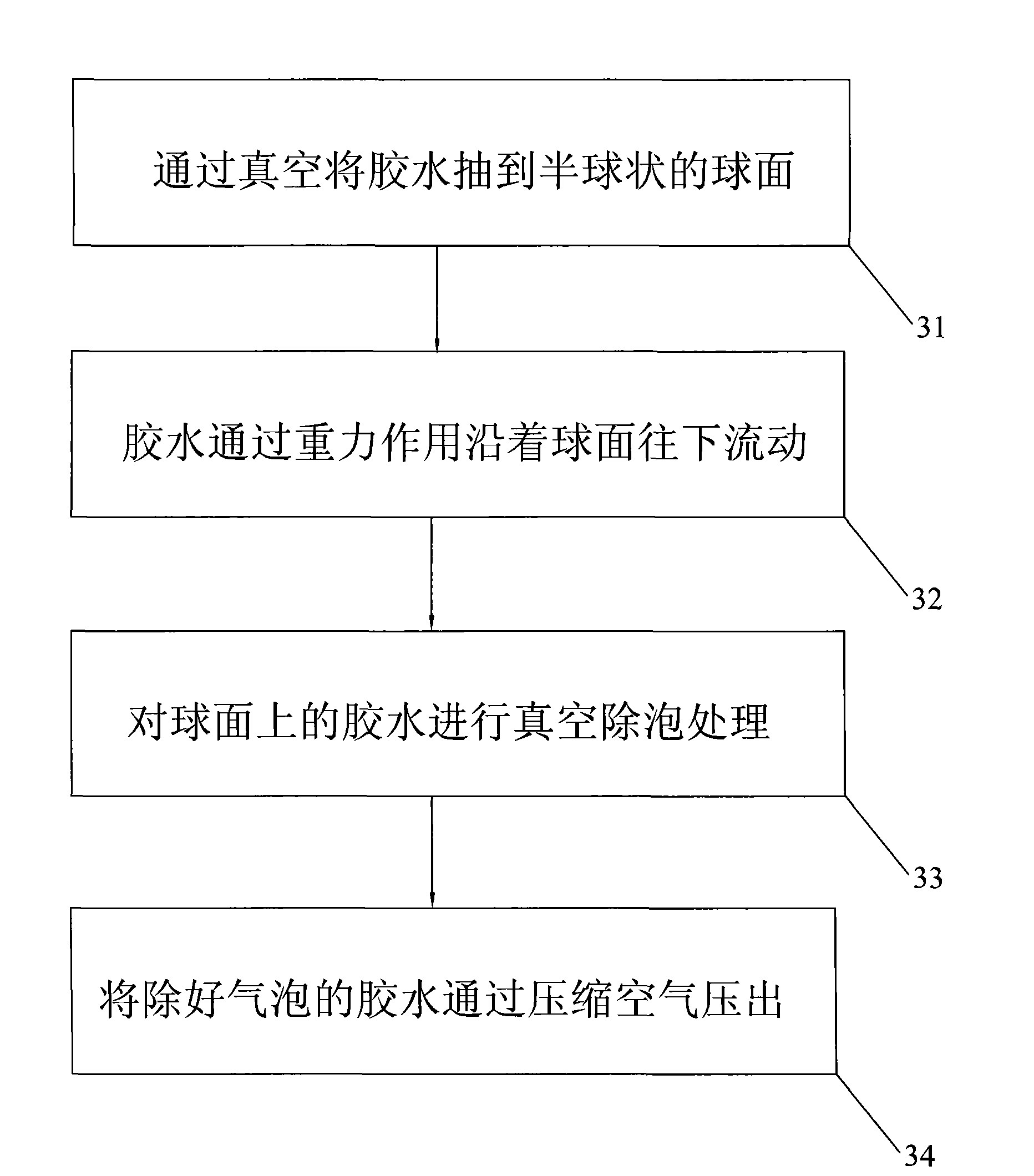

[0022] refer to figure 2 , the steps when using the glue defoaming device of the present invention to carry out glue defoaming are:

[0023] (31) The glue is pumped to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com