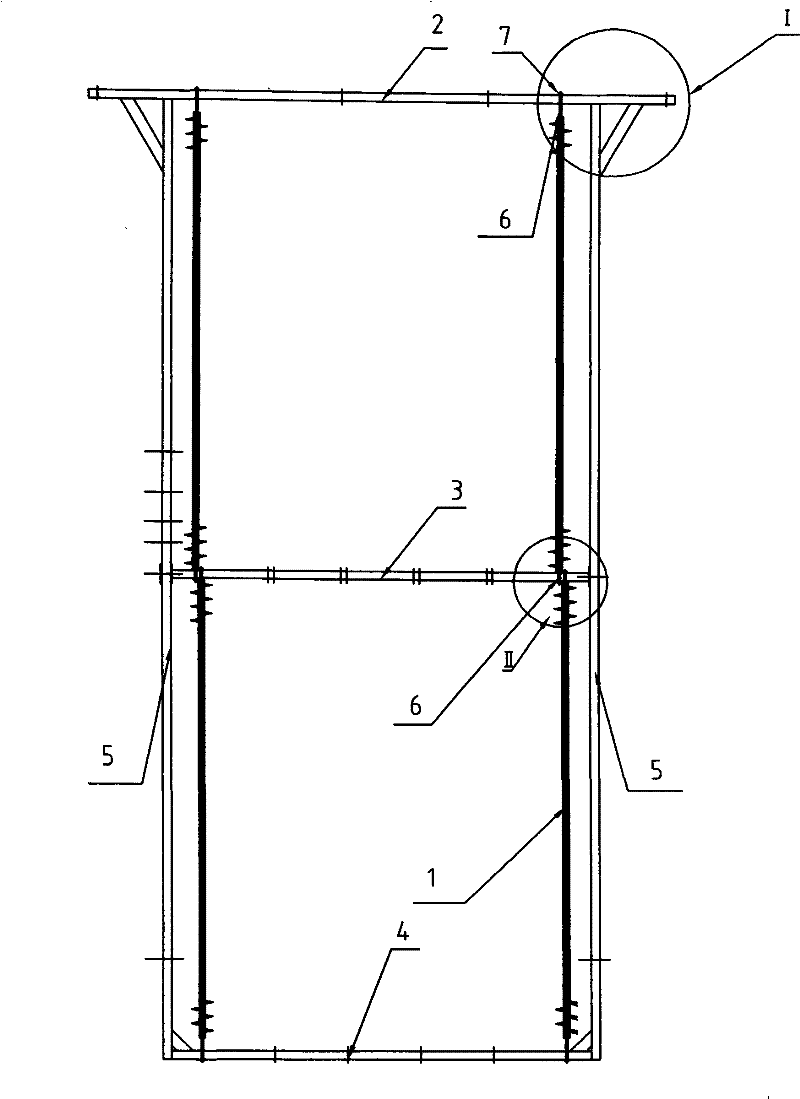

A Novel Connection Structure and Connection Method of Cathode Wire and Cathode Frame

A cathode frame and connection structure technology, applied in the direction of electrode conveying device, electrostatic separation, etc., can solve the problems of easy disconnection at the connection point and inability to run stably for a long time, so as to overcome easy disconnection, stable connection and good performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

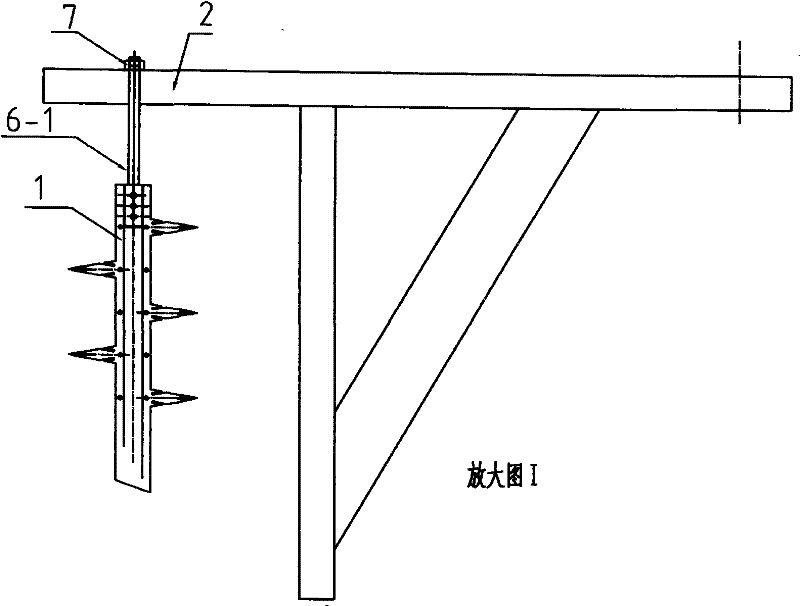

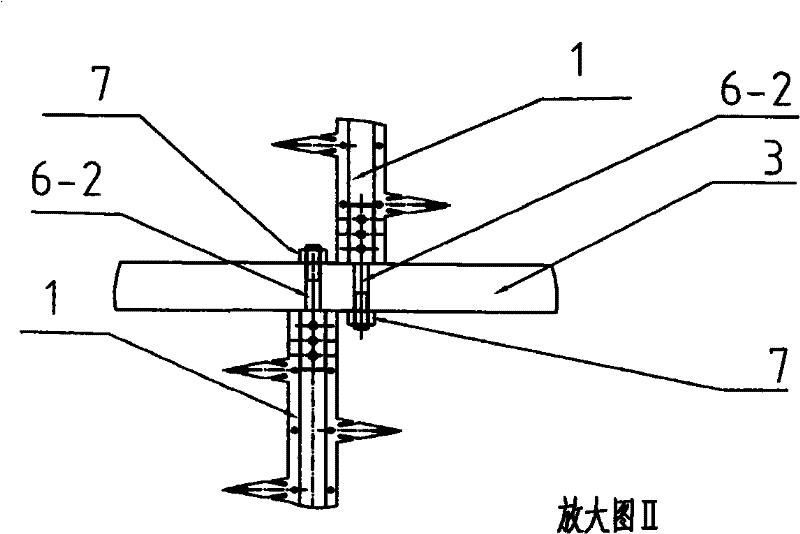

[0021] The cathode wire connection method installed between the upper frame and the middle frame: insert two long and short screws at both ends of the cathode wire, first insert one end of the long screw into the upper frame, and then move the cathode wire up to the long screw At the maximum position of the bottom, at this time, the lower end of the cathode line is one end of the short screw that can be smoothly inserted into the middle frame adjacent to the upper frame, adjust the position of the cathode line, install nuts on both ends, and weld them firmly, the long screw end The nut and the screw are welded and fixed so as to expand with heat and contract with cold, and the nut at the end of the short screw is welded and fixed with the transverse frame as a whole to prevent the rotation of the cathode wire. That is, the cathode wire can be firmly installed between the upper frame and the middle frame. Even if the nut falls off, the cathode wire will not fall off. Therefore...

Embodiment 3

[0023] Install the cathode wire between the lower frame and the middle frame, insert the end with the long screw into the lower frame, push the cathode wire down to the maximum position at the bottom of the long screw, then the top of the cathode wire is the end of the short screw and it can be smoothly Insert it into the middle frame adjacent to the lower frame, adjust the position of the cathode line, install nuts at both ends, and weld them firmly. The long screw end nut and the screw are welded and fixed so as to expand with heat and contract with cold. The frame is welded and fixed as a whole to prevent the cathode wire from rotating. That is, the cathode wire can be firmly installed between the lower frame and the middle frame. Even if the nut falls off, the cathode wire will not fall off. Therefore, the disadvantage that the connection between the cathode line and the cathode frame is easy to drop is overcome.

[0024] figure 2 It is an enlarged view of the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com