Sliding device of dual-tower-mast giant self-lifting crane

A technology of lifting equipment and sliding devices, applied in the direction of cranes, layered products, metal layered products, etc., can solve the problems of high friction resistance on the sliding surface, huge pressure on difficult and heavy objects, easy deformation, etc., and achieve surface hardness Large, reduced frictional resistance, high bending strength and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

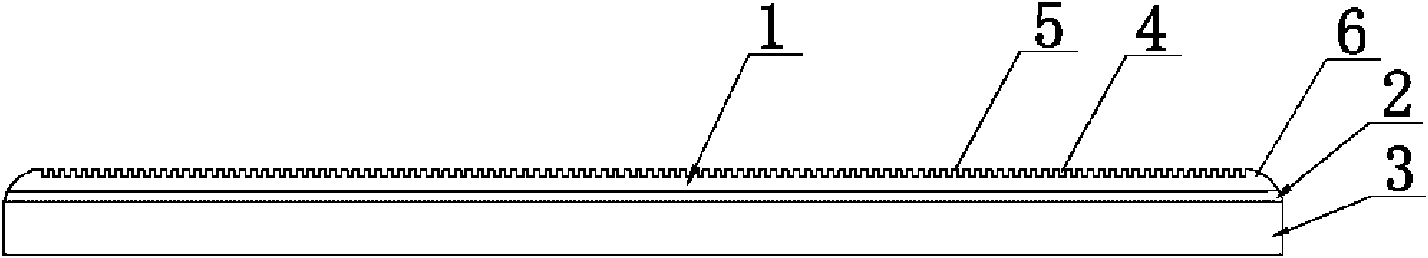

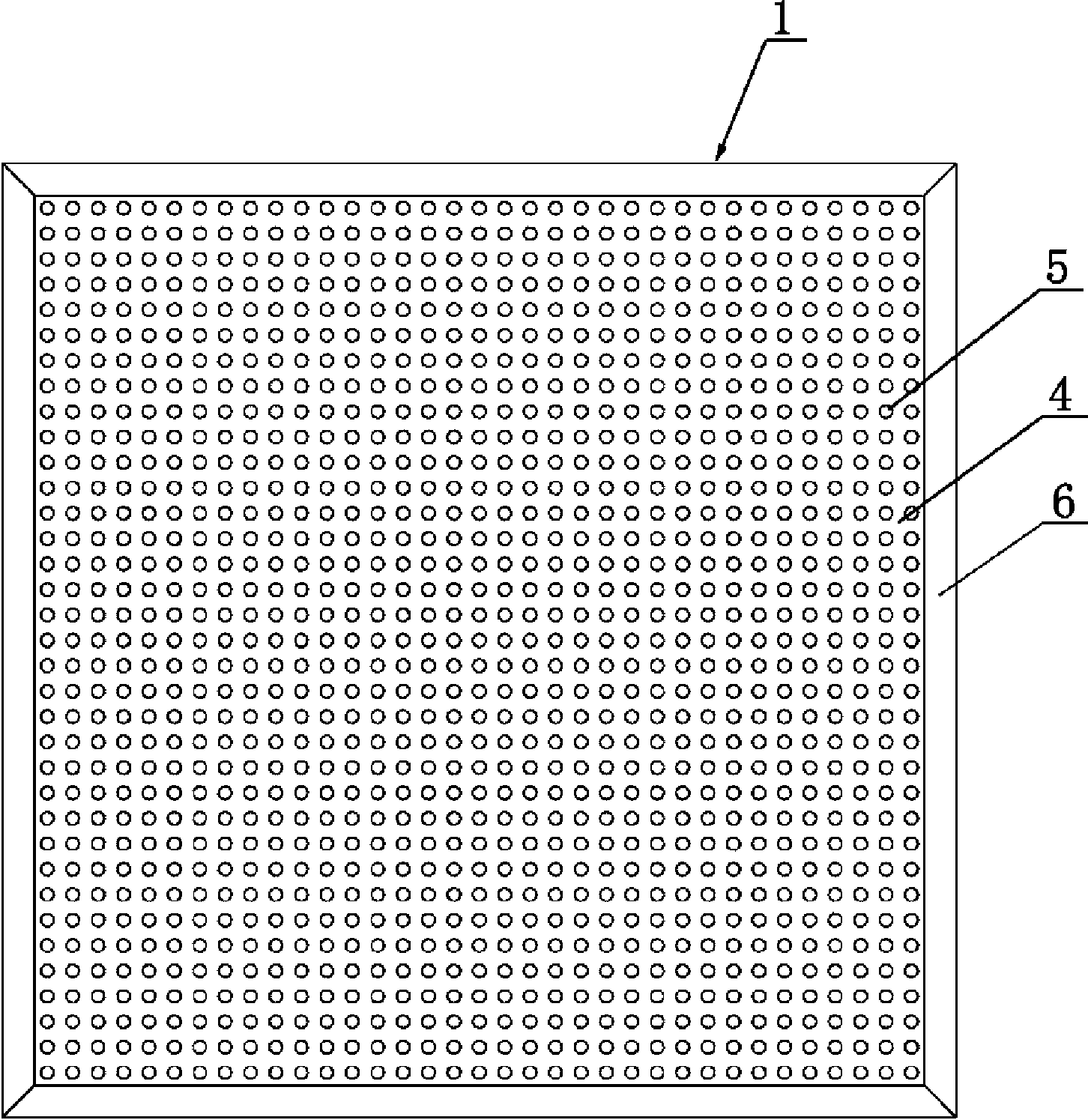

[0013] Examples see figure 1 As shown, the sliding device of this double tower mast giant self-elevating lifting equipment is composed of a PTFE plate 1, an elastic backing plate 2 and a steel bottom plate 3 bonded from top to bottom. The PTFE plate The upper surface is uniformly covered with granular micro-protrusions 5, the gaps between the micro-protrusions are oil injection holes 4, and a circle of guards 6 is formed around the tetrafluoro plate, and the height of the guards is the same as that of the micro-protrusions 5 . The above-mentioned elastic backing plate 2 can be rubber or plastic.

[0014] The invention can be processed into a square shape, and the use is not limited by the direction, as long as the direction of the force is changed, it will walk in the opposite direction of the force, which is very convenient to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com