Antiscaling alloy

An alloy and anti-scaling technology, applied in the field of anti-scaling, can solve the problems of ineffective softening, time-consuming and labor-intensive efficiency of descaling, decrease in thermal efficiency, etc., so as to solve the problem of extra energy consumption or pollutant discharge, low price, and forming a trend reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of antifouling alloy, alloy composition is as shown in table 1 by weight percentage;

[0032] Table 1

[0033] C

Si

Ni

Cu

Zn

Ti

V

Cr

mn

Re

sn

Fe

0.07

0.56

23.2

41.2

14.1

4.0

0.5

4.4

3.5

0.1

0.8

margin

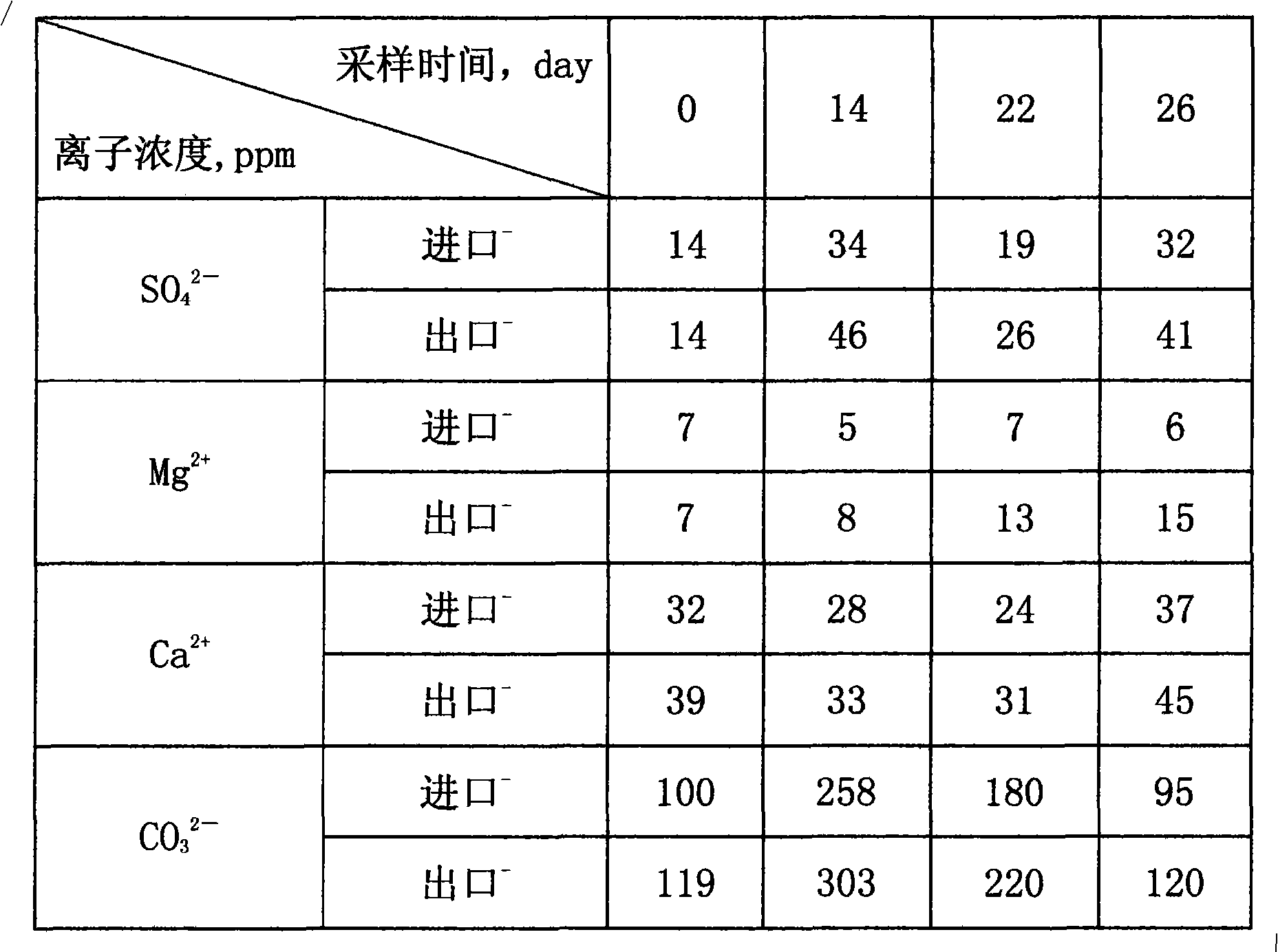

[0034] The anti-scaling alloy is applied to the heating furnace manifold of a water system, and samples are taken at the inlet and outlet respectively, with a flow rate of 5000m 3 / sky.

[0035] The anti-scaling alloy is specifically used in a powder state and packed in a special tank. Due to the huge surface area of the powder, when water flows through the tank, it has sufficient contact with the powdered anti-scaling alloy. Through the electrochemical effect between the powdered anti-scaling alloy and water, the anti-scaling alloy releases a large number of electrons to improve the solubility of the scaling ions in the wa...

Embodiment 2

[0040] A kind of antifouling alloy, alloy composition is as shown in table 3 by weight percentage:

[0041] table 3

[0042] C

Si

Ni

Cu

Zn

Ti

V

Cr

mn

Re

sn

Fe

0.06

0.7

14.2

33.1

15.1

3.1

0.3

7.4

5.5

0.3

0.6

margin

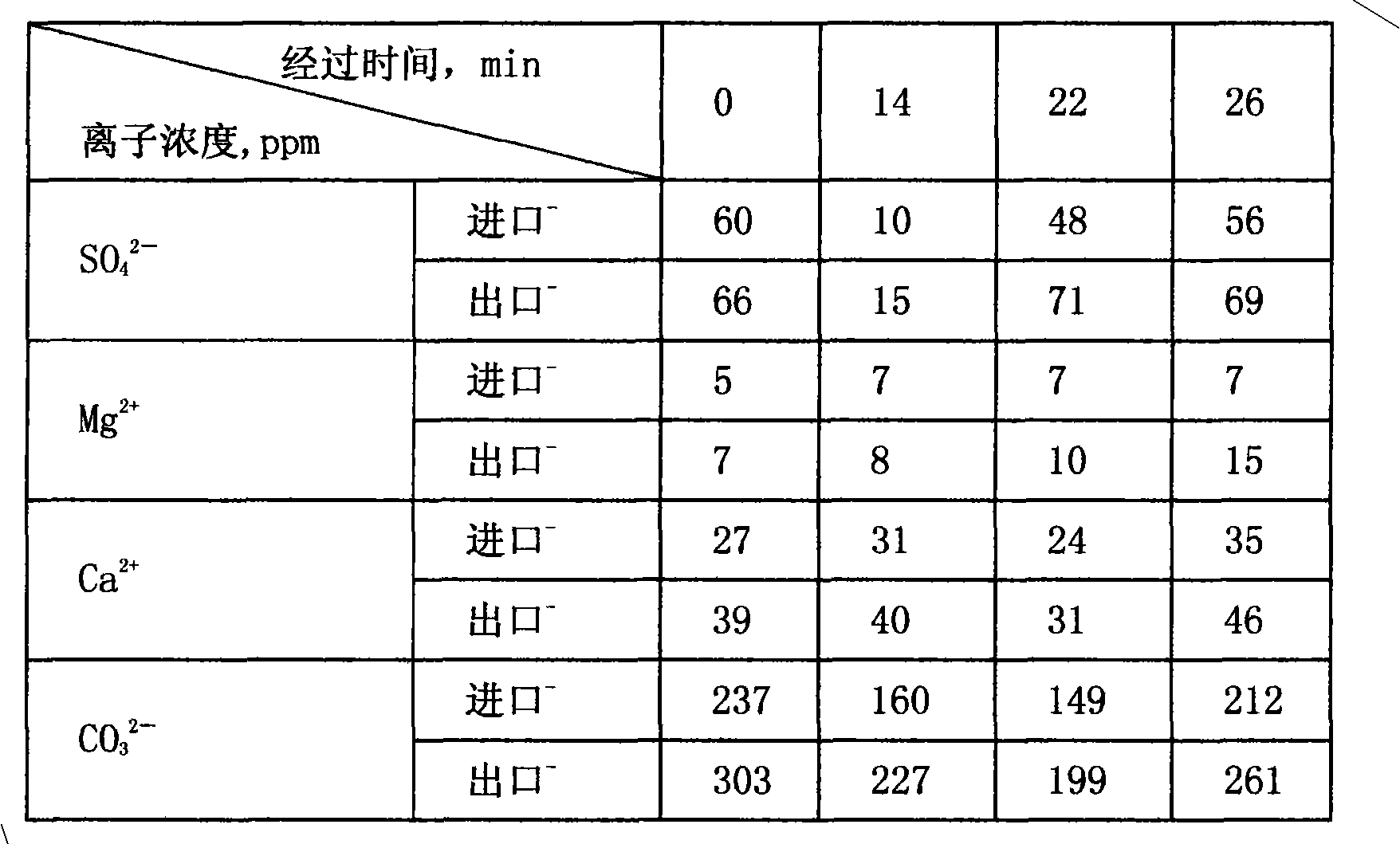

[0043] Unlike Example 1, the antifouling alloy was used in a porous form, not in a powder state. The anti-scaling device is a tank body equipped with alloy porous blades. During use, the blades rotate and fully contact with the liquid flowing through the tank body. The alloy anti-scaling device is installed on the water system heating furnace header. Through the electrochemical effect between the alloy and water, the alloy releases a large number of electrons to improve the solubility of scale-forming ions in water.

[0044] The test data are shown in Table 4: Due to the electrostatic catalysis of the alloy, despite the large...

Embodiment 3

[0048] An anti-fouling alloy, its main characteristics are as follows:

[0049] 1) a kind of antifouling alloy, its concrete composition and the weight percent of each composition are specifically as follows:

[0050] Ni: 16%, Cu: 30%, Zn: 15%, Ti: 5%, V: 0.4%, Cr: 6%, Mn: 4%, B: 0.1%, four of La, Ce, Pr, Nd One or its combination: 0.3%, Sn: 0.2%, C≤0.10%, Si: 0.5%, Fe: balance.

[0051]2) The specific form of the anti-fouling alloy is one of the following or a combination thereof: powder, granular, spherical, porous plate, layered sprayed on the surface of other materials. The particle size of powder is required to be about 0.9-20mm; the particle size of granular is required to be about 1.5mm, and the particle size of spherical shape is required to be about 8mm.

[0052] When the use state of the anti-fouling alloy is mainly powder, the outlet or / and inlet of the anti-fouling device for containing the anti-fouling alloy is equipped with a filter screen. The pore size of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com