Post-poured hidden coping construction method for converting simply supported beams into continuous beams

A technology of simply supported beams and covered beams, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of construction cost and construction speed that need to be further improved, and achieve the effects of lightweight components, convenient transportation, and compact body shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

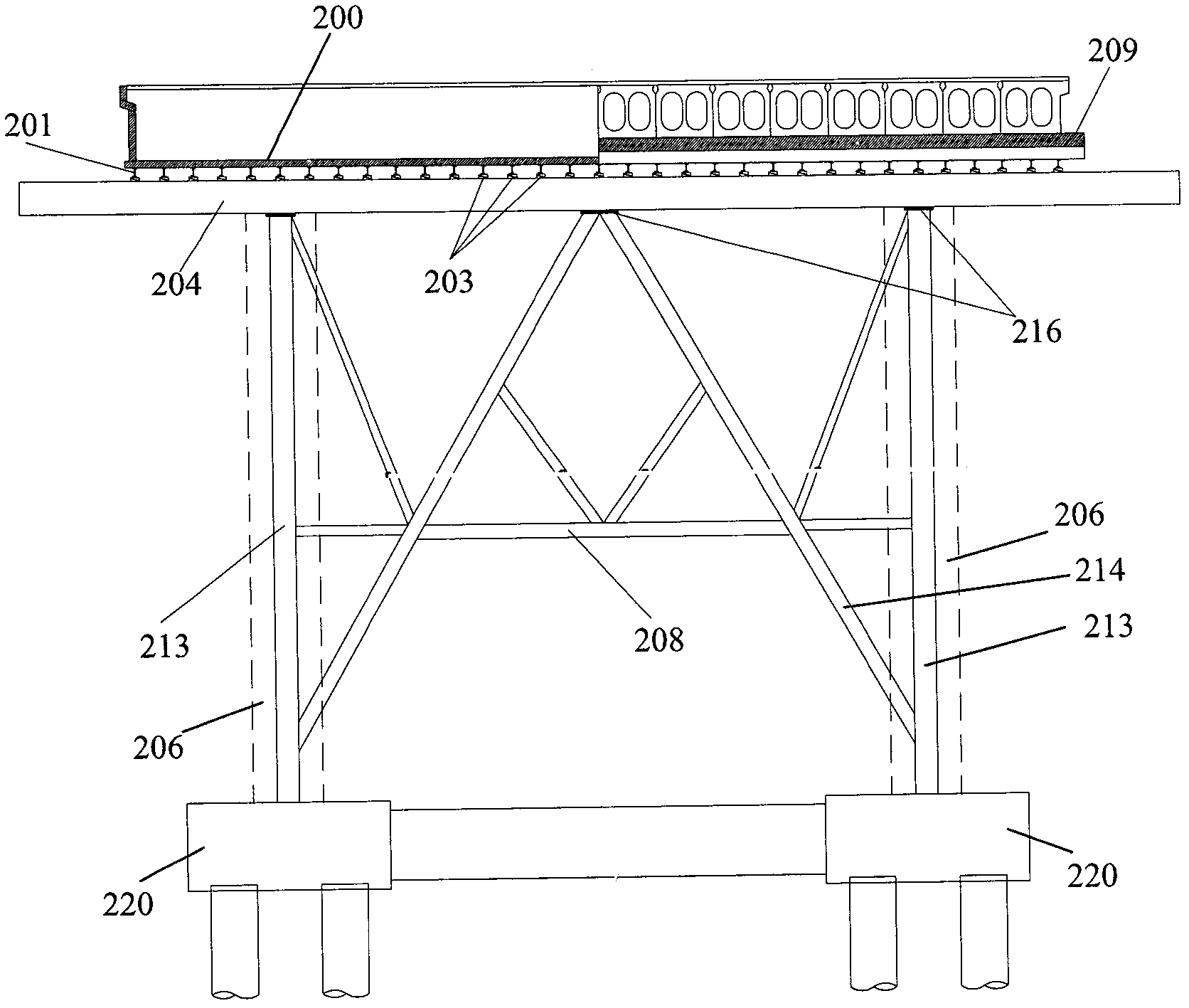

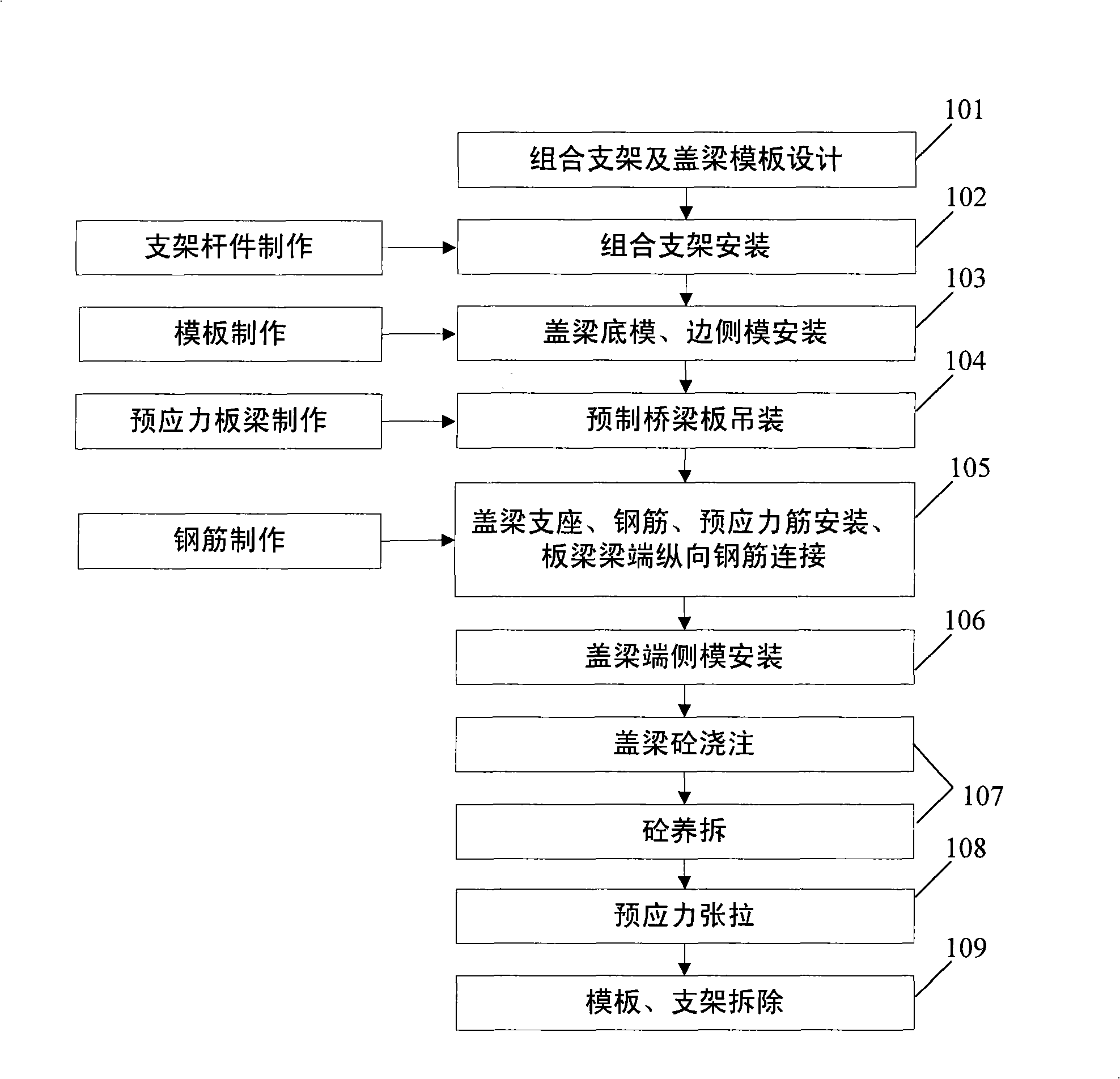

[0031] Such as figure 1 As shown, in process 101, the structural design of the combined support and cast-in-place cover beam (or simply cover beam) formwork is carried out, wherein the combined support is based on the installation construction load of the prefabricated slab girder and the cast-in-place construction load of the cast-in-place cover beam, At the same time, considering the working load of the operating platform at both ends of the cast-in-place cover beam, the structural design is carried out according to the most unfavorable working condition of the combined support. The material of the combined support is Q235 steel and steel plate of different types and specifications. The specifications and sizes of seams are determined by design calculations.

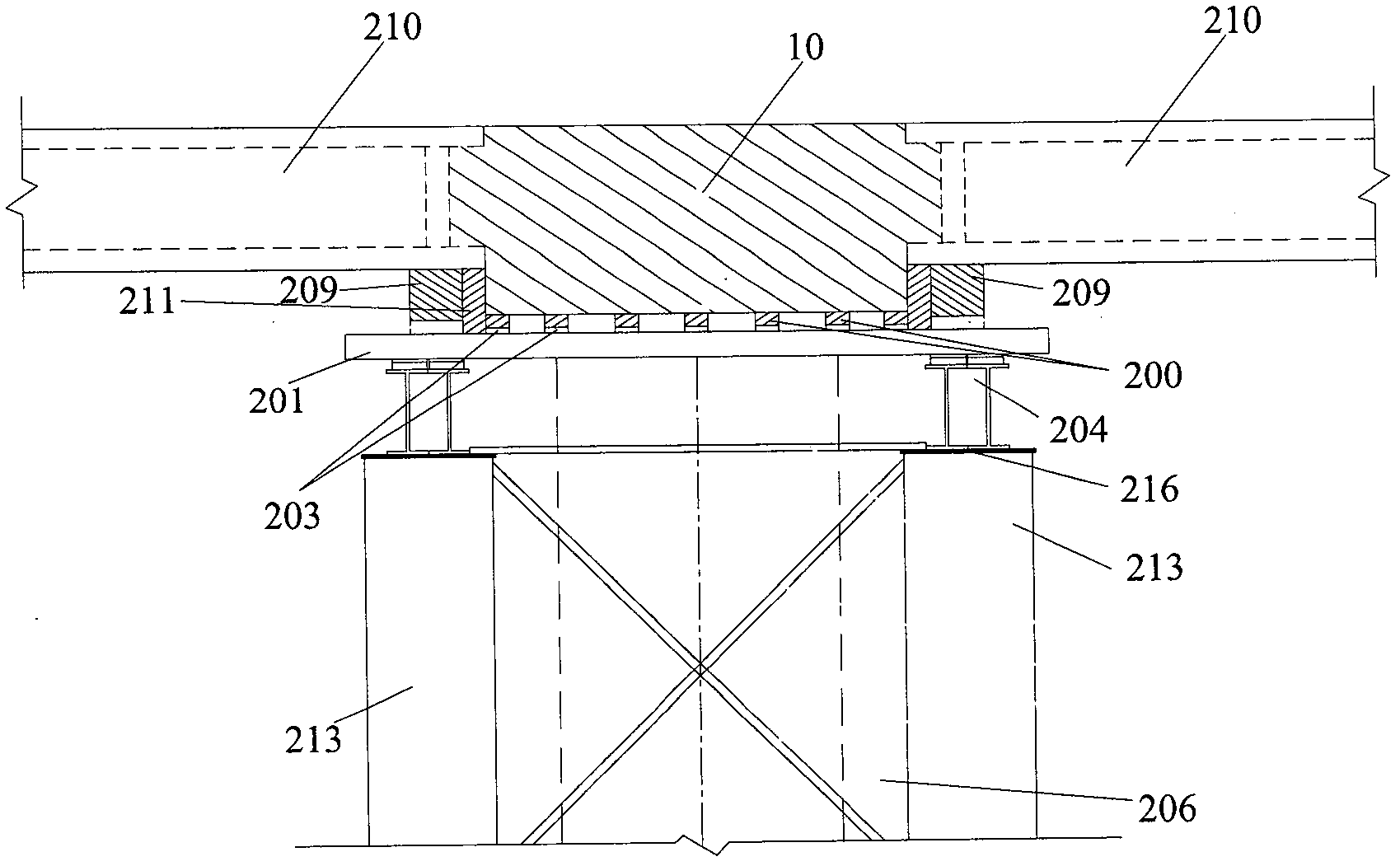

[0032] The formwork of cast-in-place cover beam 10 adopts wooden formwork to carry out construction, and the panel of its base mold is plastic surface nine splints, as figure 2 with image 3 As shown, the corrugated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com